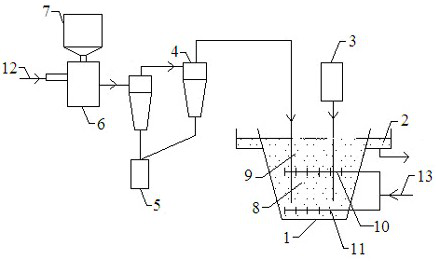

A preparation method and device for a microcapsule material based on the dual control of the particle size of the substrate and the shell material

A technology of microcapsules and shell materials, applied in microcapsule preparations, microsphere preparation and other directions, can solve the problems of poor coating effect of microcapsule materials, complicated equipment and operation steps, and large droplet particle size of shell materials, etc. The effect of adaptive separation, simplified preparation steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The height-to-diameter ratio of the microcapsule reactor is 2, the cone angle is 60°, the gas holdup rate in the wrapping area is 10%, and the gas holdup rate in the separation area is 20%. The shell material is natural polymer material, surfactant, dispersant, The complex emulsion prepared by emulsifier, the substrate is strong oxidizing particles, the mass ratio of shell material to substrate is 3:1, the temperature is 67°C, and the reaction time is 1.5h. The prepared microcapsule material has a good shape. The particle size is relatively uniform, and the coating rate is 87.2%.

Embodiment 2

[0032] The height-to-diameter ratio of the microcapsule reactor is 2, the cone angle is 70°, the gas holdup rate in the wrapping area is 20%, and the gas holdup rate in the separation area is 30%. The shell material is natural polymer material, surfactant, dispersant, The complex emulsion prepared by emulsifier, the substrate is strong oxidizing particles, the mass ratio of shell material to substrate is 3:1, the temperature is 67°C, and the reaction time is 1.5h. The prepared microcapsule material has a good shape. The particle size is relatively uniform, and the coating rate is 89.7%.

Embodiment 3

[0034] The height-to-diameter ratio of the microcapsule reactor is 2, the cone angle is 60°, the gas holdup rate in the wrapping area is 20%, and the gas holdup rate in the separation area is 35%. The shell material is natural polymer material, surfactant, dispersant, The complex emulsion prepared by emulsifier, the substrate is strong oxidizing particles, the mass ratio of shell material to substrate is 3:1, the temperature is 67°C, and the reaction time is 1.5h. The prepared microcapsule material has a good shape. The particle size is relatively uniform, and the coating rate is 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com