Automatic and precise measuring machine for tapered bearing shims

A technology of precise measurement and tapered bearings, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as low work efficiency, low measurement accuracy, and errors, and achieve high equipment automation and ensure positional accuracy requirements. Reasonable effect of the overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

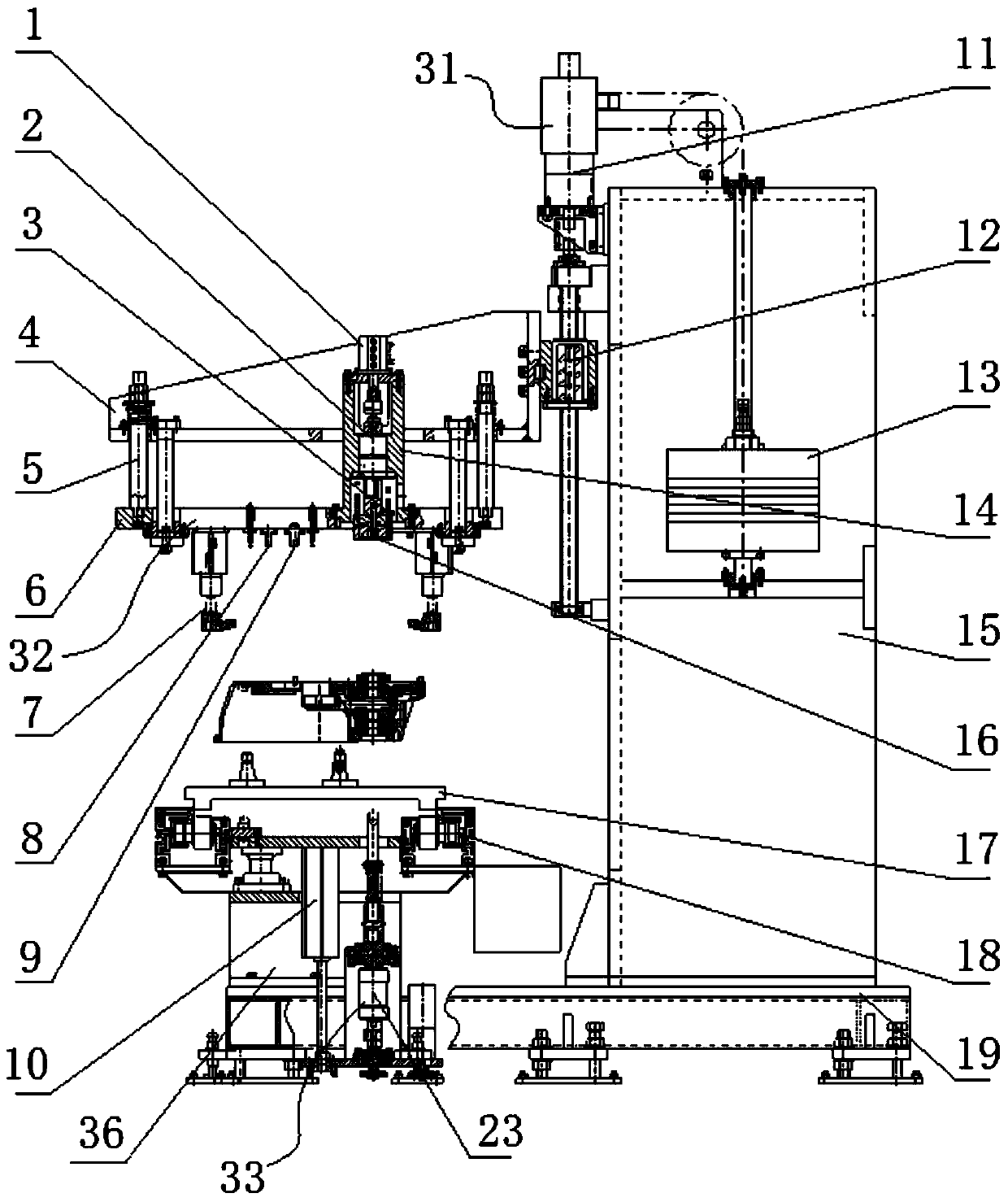

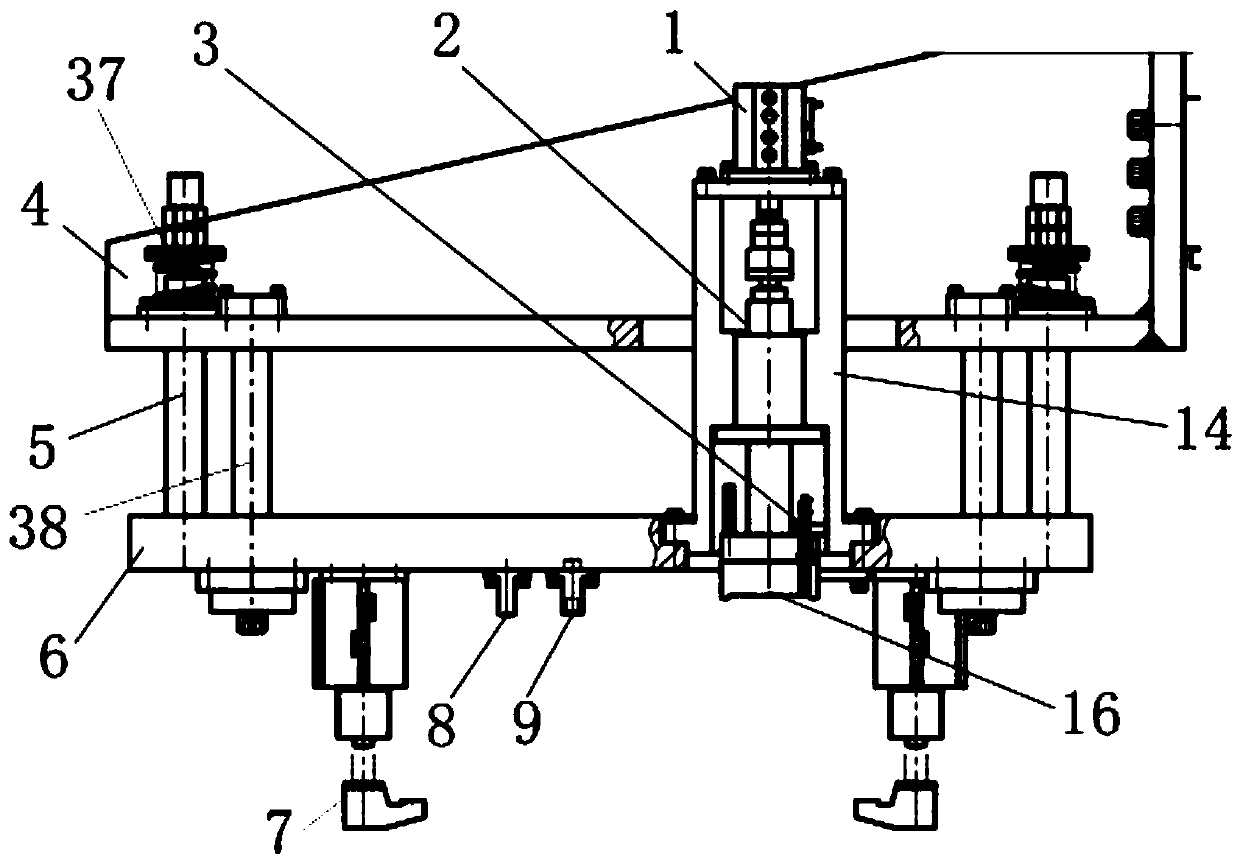

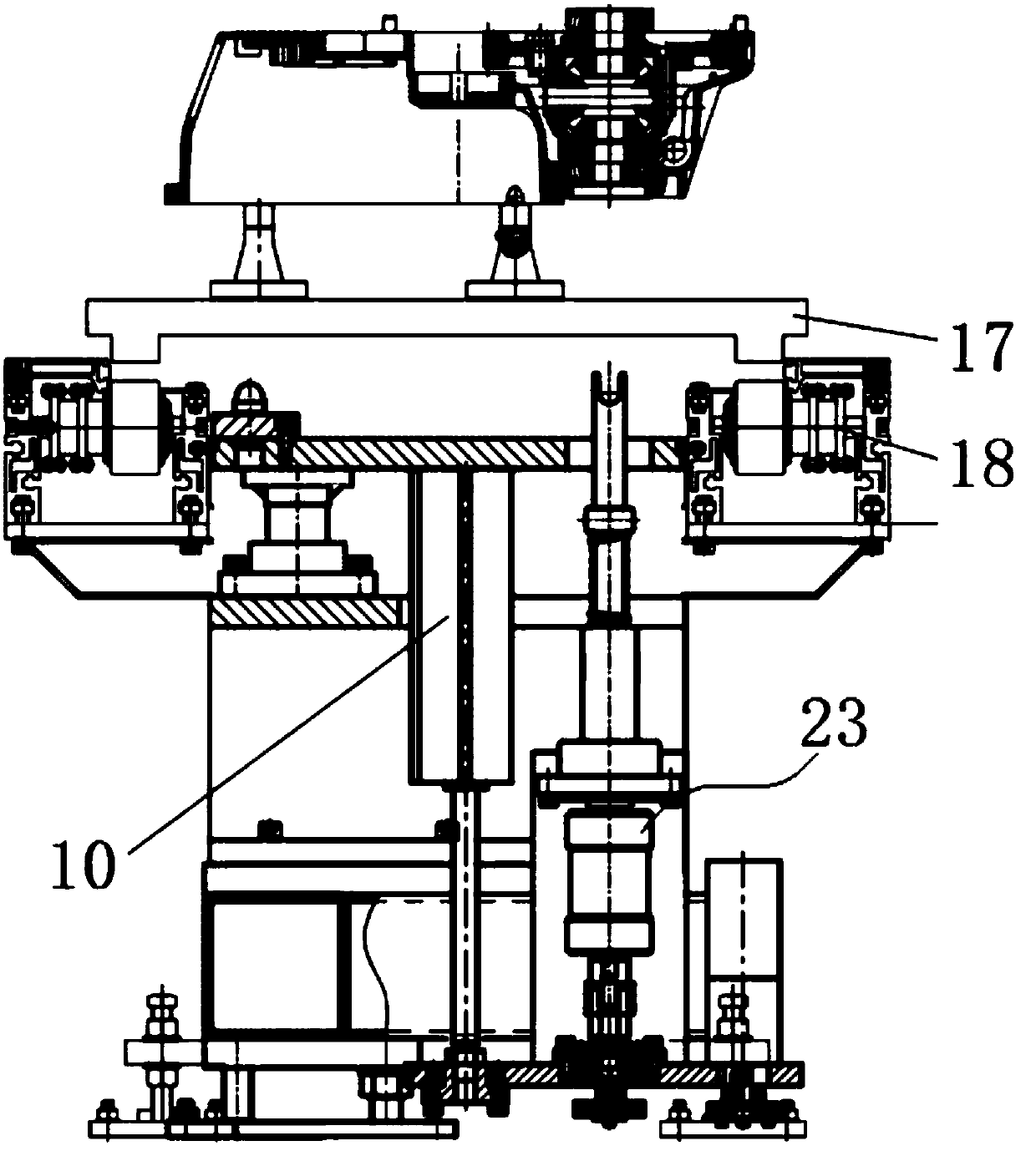

[0030] Such as Figure 1~6 As shown, the present invention includes frame 15, lifting head of bed 4, head of bed elevating mechanism 31, away from shell measuring mechanism 32, changing shell measuring mechanism 35, pallet support 36, rotation simulation mechanism 33 and pallet lifting mechanism 34 , wherein the head of the bed lifting mechanism 31 is fixedly mounted on the frame 15, the lifting head of the bed 4 is driven up and down by the head of the bed lifting mechanism 31, and the measuring mechanism 32 from the shell and the measuring mechanism 35 of changing the shell are all arranged on the lifting bed On the head 4 , a pallet support 36 is arranged directly below the lifting bed head 4 , and the rotation simulation mechanism 33 and the pallet lifting mechanism 34 are both arranged on the pallet support 36 .

[0031] Such as Figure 1~2 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com