A kind of anti-chaos rope winch with forced parallel tightness between ropes

An anti-chaotic rope and tight-fitting technology, which is applied in the direction of hoisting device and clockwork mechanism, can solve the problems of accelerating the wear and service life of the wire rope, affecting the normal use of the winch, and messing up the wire rope of the winch. The effect of the winch tangled rope problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

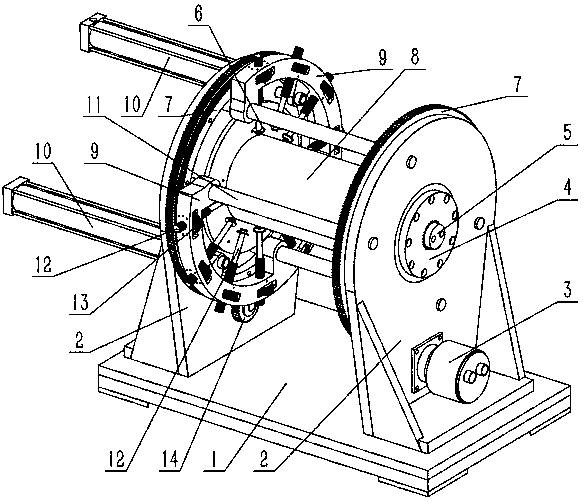

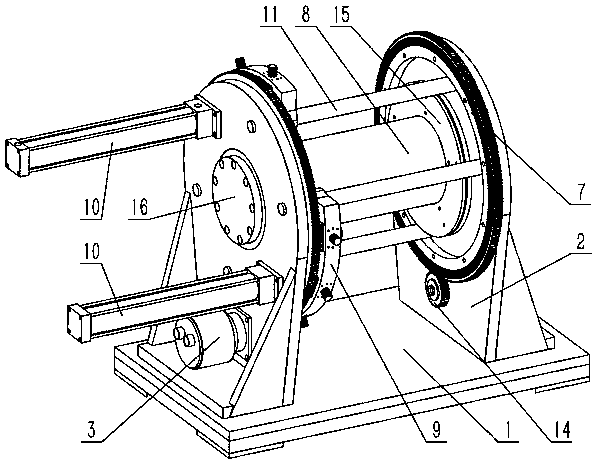

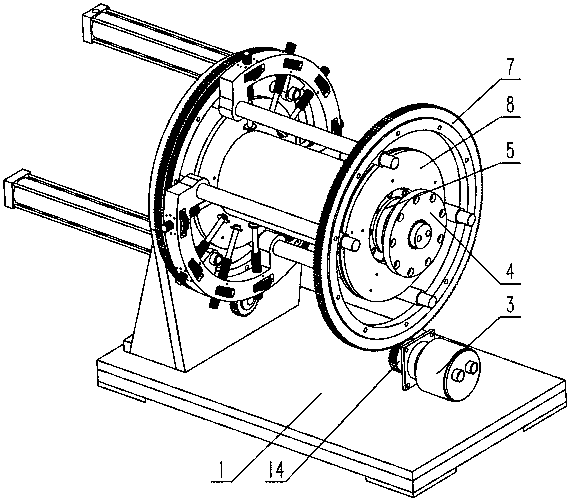

[0031] Example: such as Figure 1 to Figure 17 The rope-to-rope forced-tight anti-disorder winch shown in the drawing includes a winch bracket 1, two roller brackets 2 are installed symmetrically and vertically on both sides of the winch bracket 1, and a through hole is provided in the middle of the two roller brackets 2, one of which is A non-power end cover 16 is provided outside the through hole of the roller support 2, and a power end cover 4 is provided outside the through hole of the other roller support 2. The middle part of the power end cover 4 is provided with a spline groove, and a fixed shaft drive motor 5 is installed in the spline groove. A drum 8 is also arranged between the two drum brackets 2, and one side of the drum 8 is mounted on the inner side of the non-powered end cover 16 through a bearing 17, and the other side is mounted on the outside of the shell of the fixed-axis drive motor 5 . The inner sides of the two roller brackets 2 are also respectively ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com