Regulating method for fish culture using biogas slurry

A biogas slurry and fish pond technology, which is applied in fish farming, application, climate change adaptation, etc., can solve the problems of centralized discharge of aquaculture wastewater, utilization and consumption of difficult-to-arable land, and large amount of biogas slurry, and promote the purification of biogas slurry. , saving bait and realizing the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

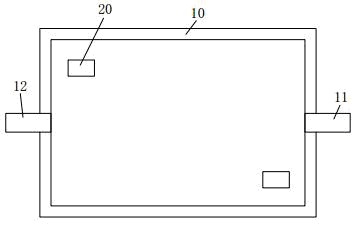

[0020] Example 1 Reference figure 1 and figure 2

[0021] A control method for fish farming using biogas slurry, comprising the following steps:

[0022] 1) A fish pond 10 is prefabricated. The location of the fish pond needs to be located in a mild climate, good lighting conditions, and non-polluting area; the upper side of the fish pond is provided with a biogas slurry inlet pipe 11, and the other side of the upper part of the fish pond is provided with There is an outlet pipe 12 for controlling the water level, and the bottom of the fish pond is provided with a drain pipe 13; the area of the fish pond is 1.5 mu, and the water storage capacity is 2000m 3 , install two multi-functional shallow aerobic aeration devices in the fish pond. After the fish pond is full of water, start to inject biogas slurry, and turn on the multi-functional shallow aerobic aeration device to cultivate plankton and aerobic microorganisms in the water .

[0023] 2) One week later, fish fry wi...

Embodiment 2

[0028] Example 2 Reference figure 1 and figure 2

[0029] A control method for fish farming using biogas slurry, comprising the following steps:

[0030] 1) A fish pond 10 is prefabricated. The location of the fish pond needs to be located in a mild climate, good lighting conditions, and non-polluting area; the upper side of the fish pond is provided with a biogas slurry inlet pipe 11, and the other side of the upper part of the fish pond is provided with There is an outlet pipe 12 for controlling the water level, and the bottom of the fish pond is provided with a drain pipe 13; the area of the fish pond is 1.75 mu, and the water storage capacity is 2300m 3 , install two multi-functional shallow aerobic aeration devices in the fish pond. After the fish pond is full of water, start to inject biogas slurry, and turn on the multi-functional shallow aerobic aeration device to cultivate plankton and aerobic microorganisms in the water .

[0031] 2) One week later, fish fry w...

Embodiment 3

[0036] Example three reference figure 1 and figure 2

[0037] A control method for fish farming using biogas slurry, comprising the following steps:

[0038] 1) A fish pond 10 is prefabricated. The location of the fish pond needs to be located in a mild climate, good lighting conditions, and non-polluting area; the upper side of the fish pond is provided with a biogas slurry inlet pipe 11, and the other side of the upper part of the fish pond is provided with There is an outlet pipe 12 for controlling the water level, and the bottom of the fish pond is provided with a drain pipe 13; the area of the fish pond is 2.0 mu, and the water storage capacity is 2600m 3 , install two multi-functional shallow aerobic aeration devices in the fish pond. After the fish pond is full of water, start to inject biogas slurry, and turn on the multi-functional shallow aerobic aeration device to cultivate plankton and aerobic microorganisms in the water .

[0039] 2) One week later, fish fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com