Transport fixing equipment for liquid level alarm

A fixed equipment and alarm technology, applied in the petroleum field, can solve the problems of cumbersome steps and long time consumption, and achieve the effect of improving efficiency and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

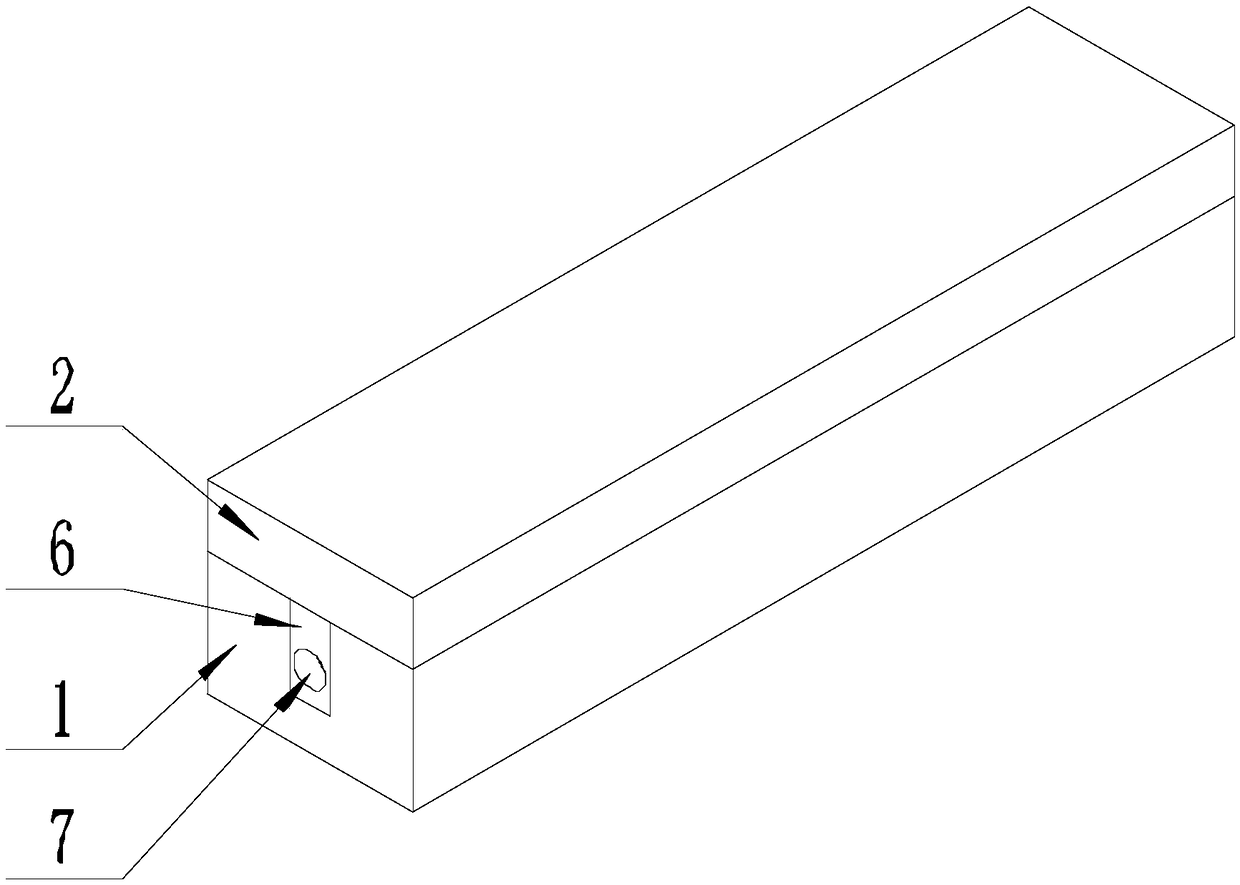

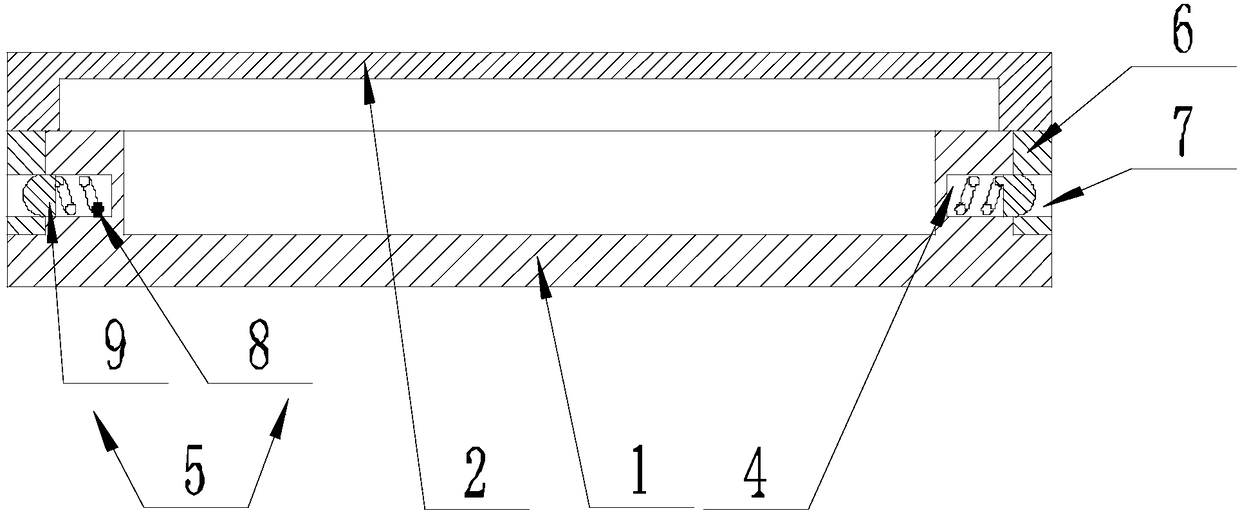

[0036] Such as Figure 1-Figure 5 As shown, the transportation fixture for the liquid level alarm of the present invention includes a packing case 1 and a top cover 2 located above the opening of the packing case 1, and matching bars 6 are arranged at both ends of the lower surface of the top cover 2. The bars 6 are provided with through holes 7, and the axes of the through holes 7 coincide with each other;

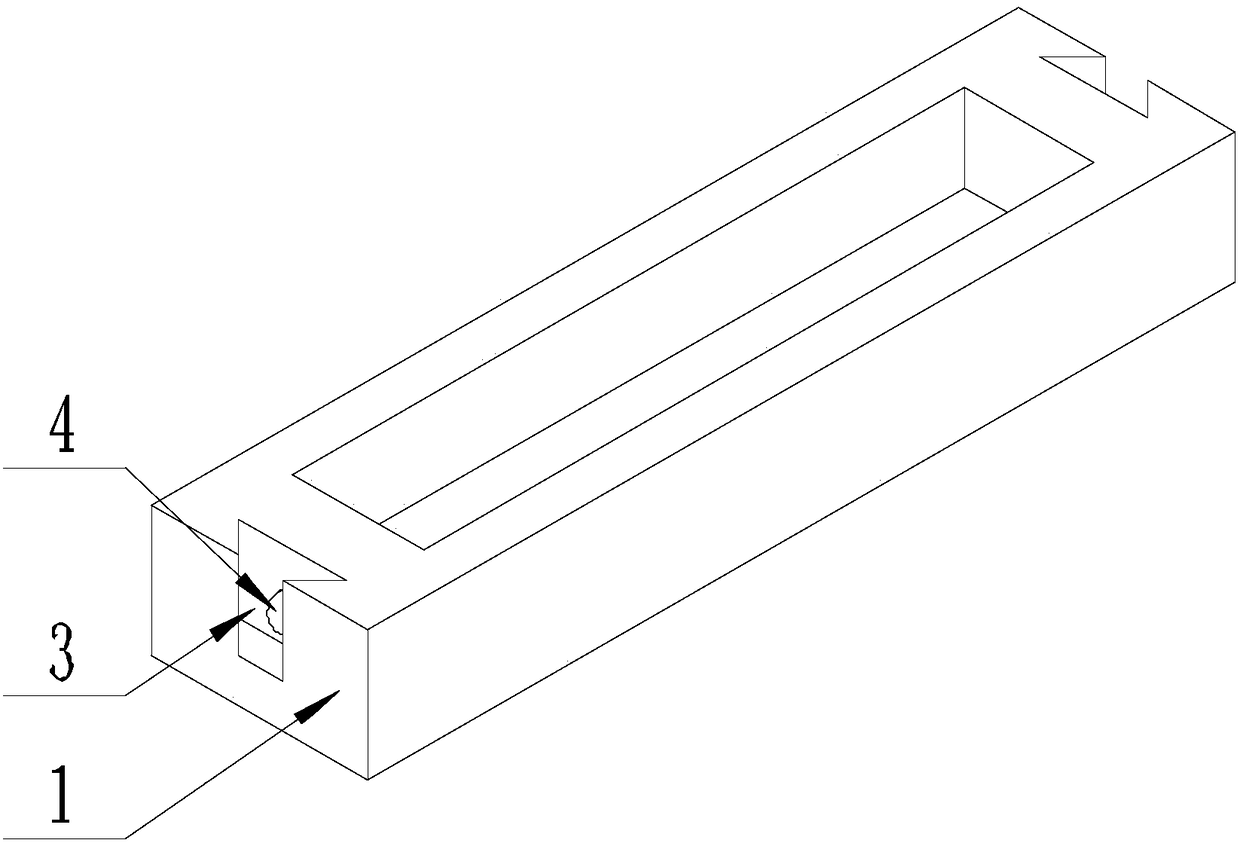

[0037] Mounting grooves 3 are all arranged on a pair of opposite outer walls of the packing box 1, the extension axes of the mounting grooves 3 are perpendicular to the horizontal plane, and mounting holes 4 are all arranged at the groove bottoms of the mounting grooves 3, and the mounting holes 4 The axis of the shaft is perpendicular to the extension axis of the installation groove 3, and telescopic parts 5 are arranged in the installation holes 4, and the telescopic direction of the telescopic parts 5 is parallel to the axis of the installation hole 4. , the matching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com