Opposed-piston and opposed-cylinder two-stroke internal combustion engine without connection rod

A two-stroke internal combustion engine, opposed piston technology, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problem of increasing the deformation and wear degree of internal combustion engine parts, which is not conducive to the compact design of the whole engine, and affects the mechanical efficiency of the internal combustion engine, etc. problems, to achieve the effect of favoring crushing and atomization, avoiding fuel short circuits, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

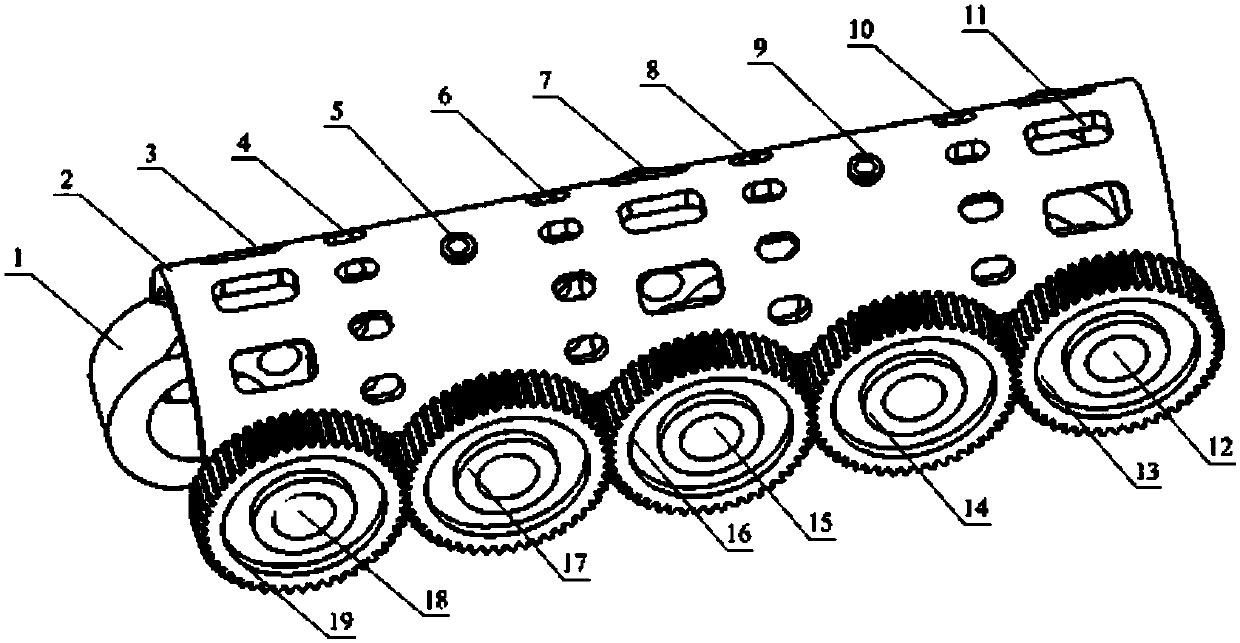

[0029] The invention provides a two-stroke internal combustion engine with no connecting rods and opposed pistons and opposed cylinders. Figure 1 to Figure 8 The structure schematic diagram of the present invention is described.

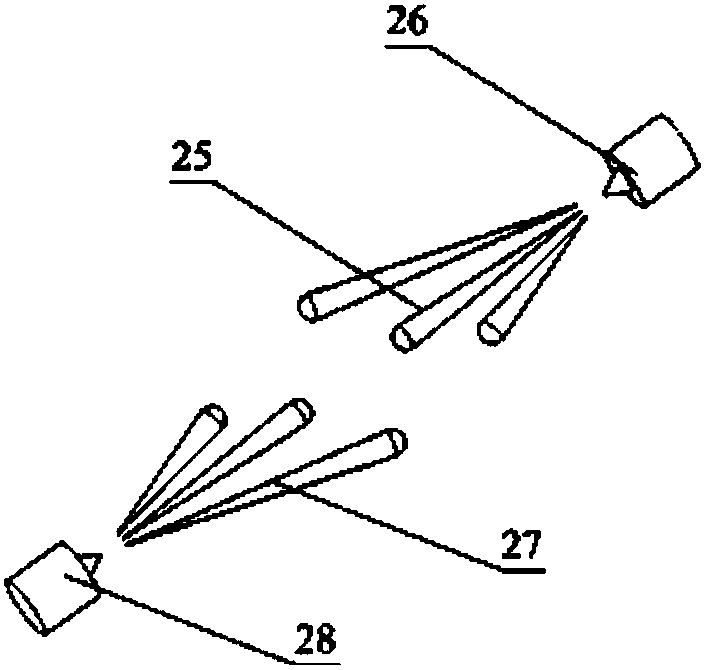

[0030] Such as Figure 1 to Figure 8 As shown, a non-connecting rod type opposed piston opposed cylinder two-stroke internal combustion engine provided by the present invention includes an opposed cylinder liner 2, and a plurality of opposed pistons are arranged in the cylinder liner 2, and the opposed pistons will The interior of the cylinder liner 2 is divided into multiple cylinders, the opposed pistons are provided with a power output mechanism, the power output mechanism is provided with a synchronization mechanism, and the cylinder liner 2 is symmetrically provided with multiple groups of double injectors, Under the constraints of the synchronous mechanism, the power output mechanism converts the reciprocating linear motion of the opposed pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com