Cross-beam-free type dispersing deflexion expansion joint mechanism

A technology of expansion joints and displacement, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of frequent expansion joint diseases, single function reduction, and complex structure, so as to achieve reliable longitudinal expansion function, simplified structure, and easy maintenance. good replacement condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

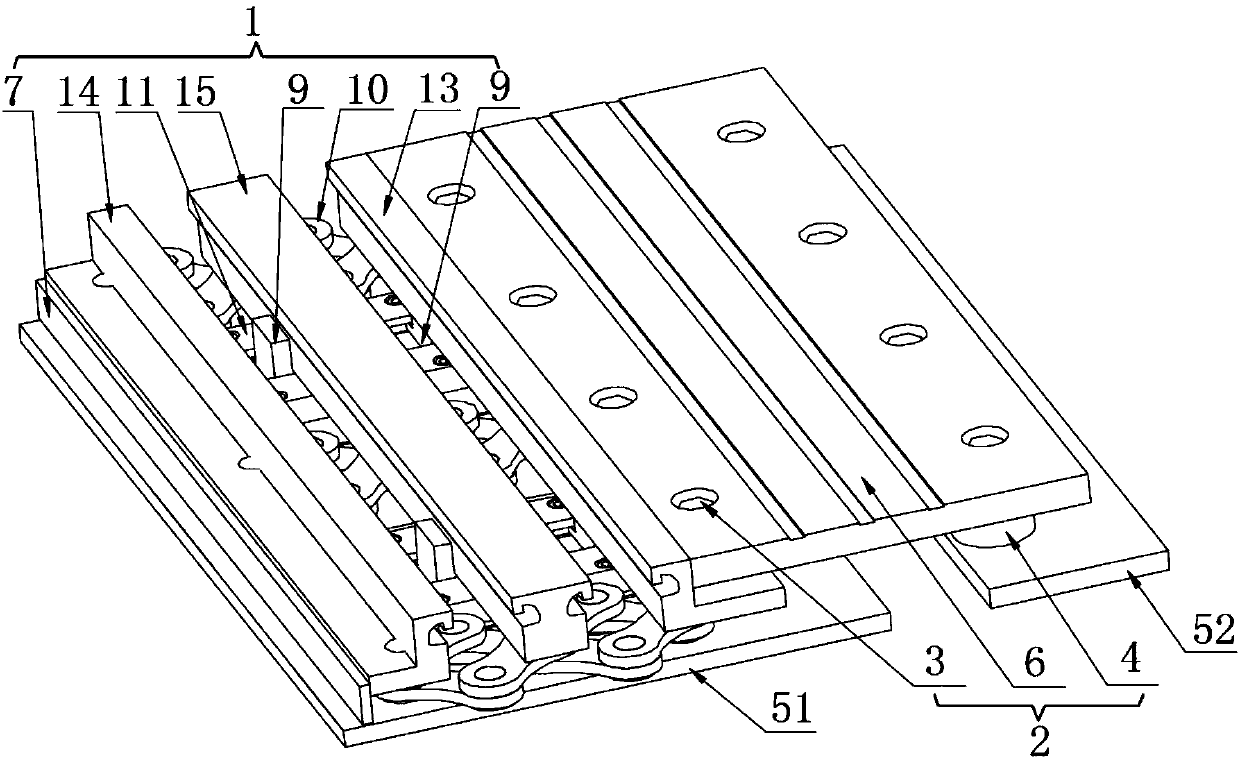

[0024] like figure 1 , 2 As shown, a cross-beam-free distributed displacement expansion joint mechanism includes a displacement assembly 1 and a spanning assembly 2. The displacement assembly 1 includes a first side beam 13, a second side beam 14, a middle beam 15, and a connecting rod assembly 10. Guide rail assembly 11, center beam slider 8, side beam slider 9 and sealing plate 7; the first side beam 13 and the second side beam 14 are respectively placed on both sides of the center beam 15; the cross-joint assembly 2 includes an outer hexagon Bolt 3, elastic support 4 and seam-spanning plate 6; displacement assembly 1 is located on the first bottom plate 51, first side beam 13, second side beam 14 and middle beam 15 are respectively intermittently arranged in the direction of the lower cross bridge. , guide rail assembly 11, side beam slider 9 and center beam slider 8; the seam-spanning assembly 2 is respectively fixed on the first side beam 13 and the second bottom plate 5...

Embodiment 2

[0029] A cross-beam-free distributed displacement expansion joint mechanism, including a displacement assembly 1 and a joint-spanning assembly 2, the displacement assembly 1 includes a first side beam 13, a second side beam 14, a middle beam 15, a connecting rod assembly 10, and a guide rail Assembly 11, middle beam slider 8, side beam slider 9 and sealing plate 7; the first side beam 13 and the second side beam 14 are respectively placed on both sides of the middle beam 15; The elastic support 4 and the seam-spanning plate 6; the displacement assembly 1 is located on the first bottom plate 51, and the first side beam 13, the second side beam 14, and the middle beam 15 are respectively intermittently arranged in the direction of the lower cross bridge. 11. The side beam slider 9 and the middle beam slider 8; the seam-spanning assembly 2 is respectively fixed on the first side beam 13 and the second bottom plate 52 through the outer hexagonal bolt 3 and the elastic support 4 . ...

Embodiment 3

[0036] A cross-beam-free distributed displacement expansion joint mechanism, including a displacement assembly 1 and a joint-spanning assembly 2, the displacement assembly 1 includes a first side beam 13, a second side beam 14, a middle beam 15, a connecting rod assembly 10, and a guide rail Assembly 11, middle beam slider 8, side beam slider 9 and sealing plate 7; the first side beam 13 and the second side beam 14 are respectively placed on both sides of the middle beam 15; The elastic support 4 and the seam-spanning plate 6; the displacement assembly 1 is located on the first bottom plate 51, and the first side beam 13, the second side beam 14, and the middle beam 15 are respectively intermittently arranged in the direction of the lower cross bridge. 11. The side beam slider 9 and the middle beam slider 8; the seam-spanning assembly 2 is respectively fixed on the first side beam 13 and the second bottom plate 52 through the outer hexagonal bolt 3 and the elastic support 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com