Mass center adjustable single-beam horizontal lifting tool

A horizontal, single-beam technology, applied in the field of spreaders, can solve the problems of cumbersome operation, single function, heavy weight, etc., and achieve the effect of small size, applicability and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] First of all, it needs to be explained that the terminology such as front, back, left, right, up, down, etc. in the present invention is only described according to the accompanying drawings for ease of understanding, and does not describe the technical solutions of the present invention and the scope of protection. limit.

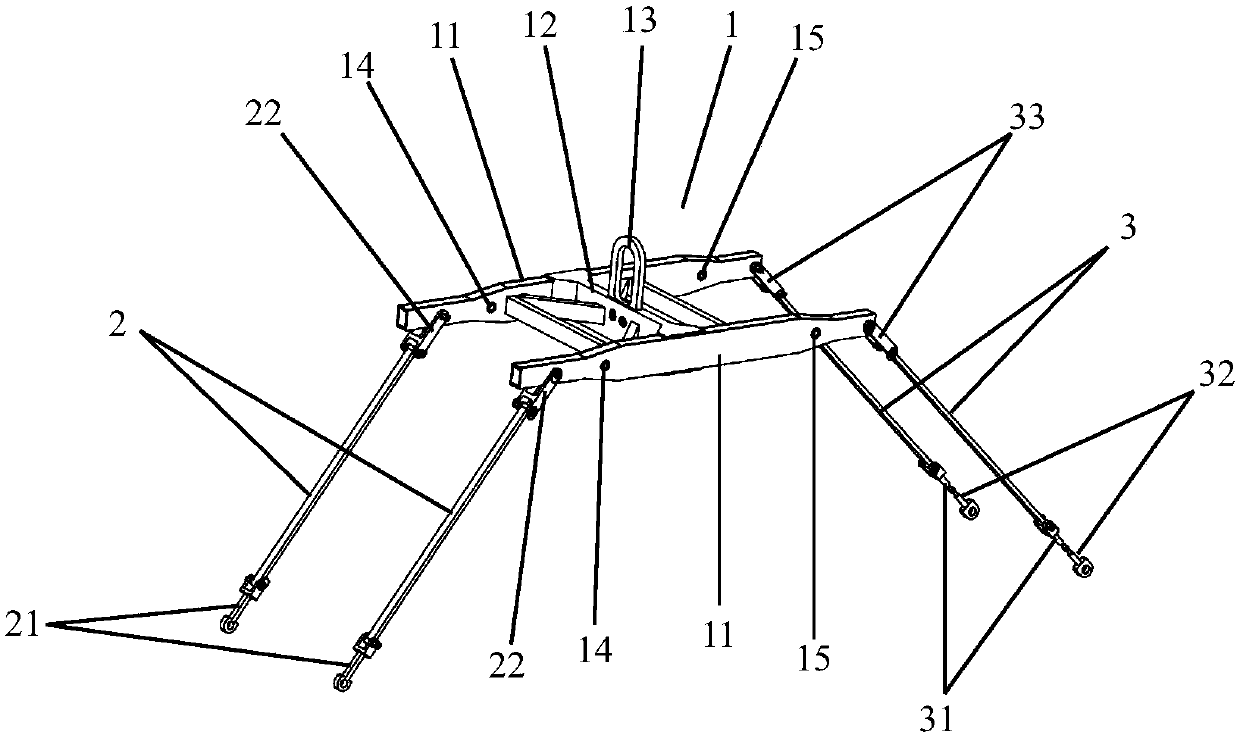

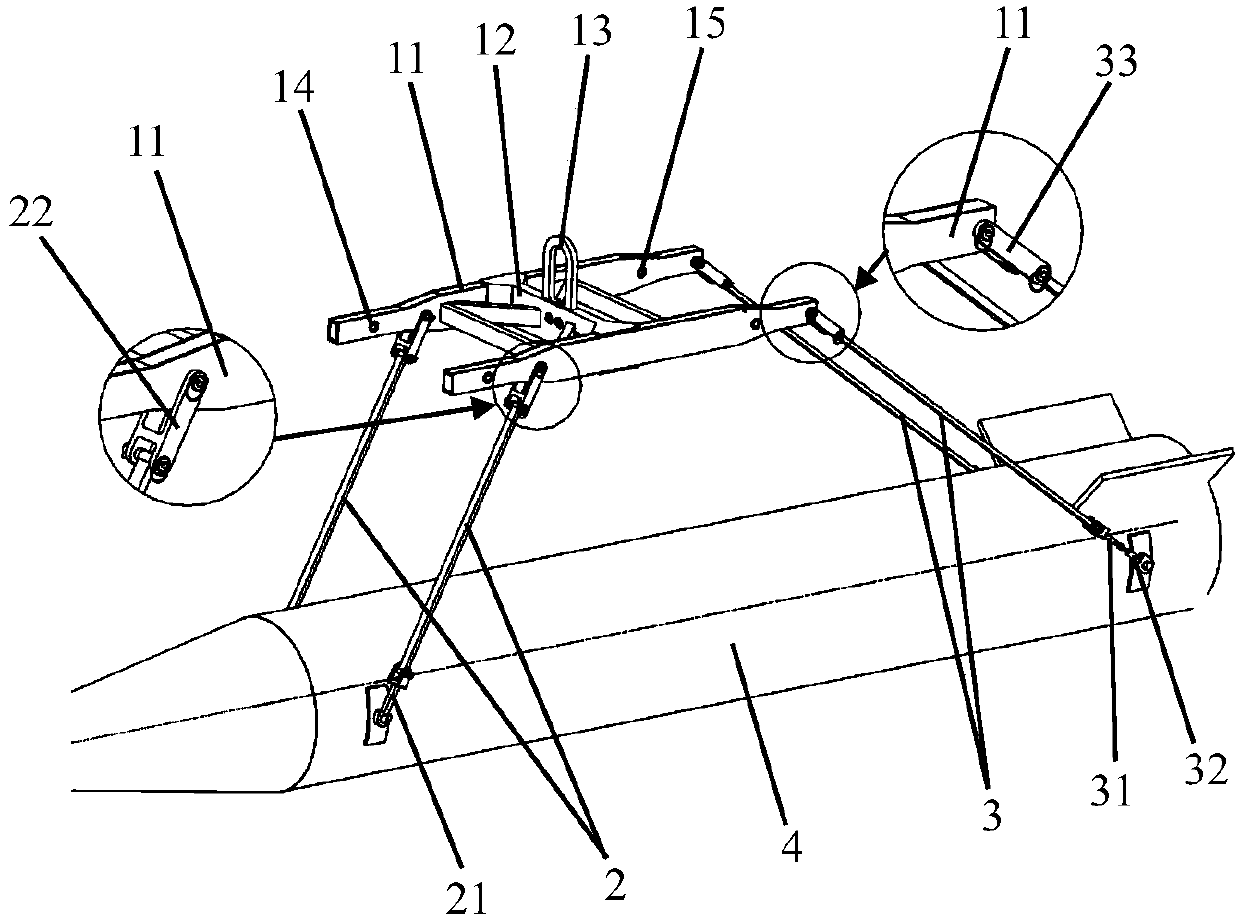

[0015] Such as figure 1 with figure 2 The specific implementation of a single-beam horizontal sling with adjustable center of mass of the present invention is shown, including a horizontally arranged "I"-shaped sling assembly 1, two front slings 2 and two rear slings 3. Let the suspension beam assembly 1 be provided with two parallel and symmetrical main beams 11, the middle of the two main beams 11 are fixedly connected by the connecting beam 12, and the lifting lug 13 is provided in the middle of the connecting beam 12. The lifting lug 13 is fixed or detachable Connection method. Let the two main beams 11 have two front hanging holes 14 spaced apa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com