Soaking type peeling device

A one-to-one, bearing plate technology, applied in the direction of agricultural machinery and implements, applications, harvesters, etc., can solve the problems of high labor intensity and low peeling efficiency, and achieve the effect of easy removal and improved peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

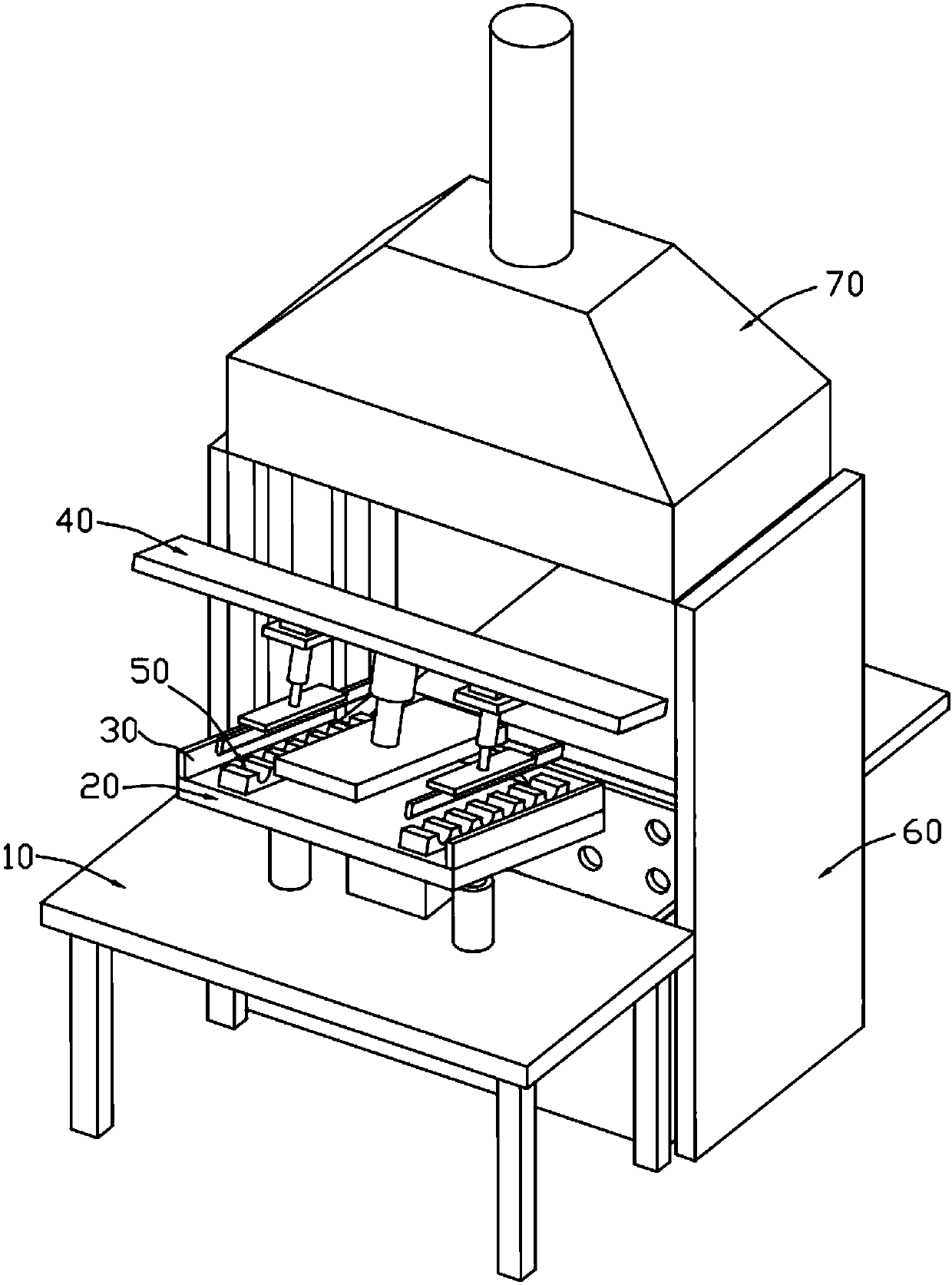

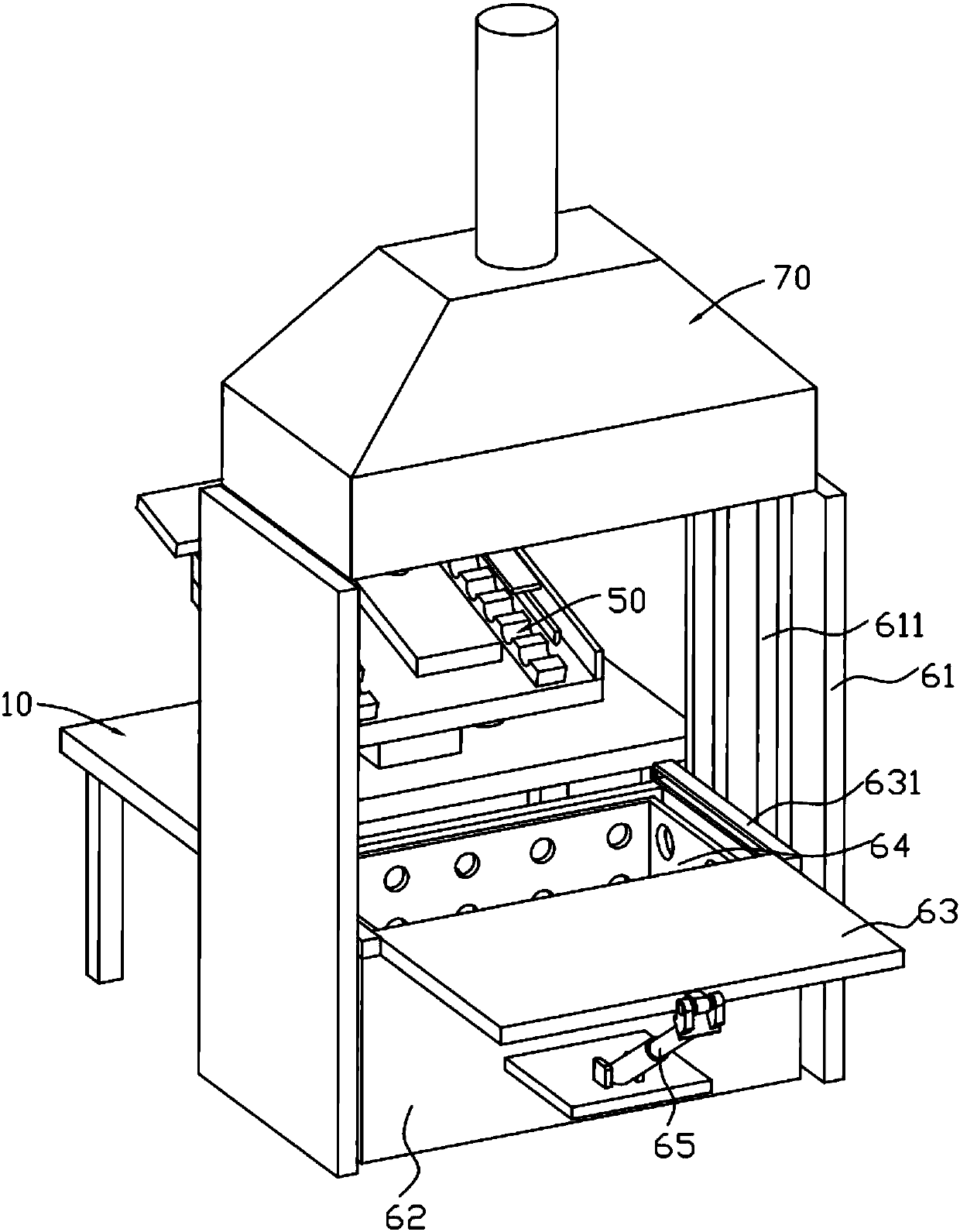

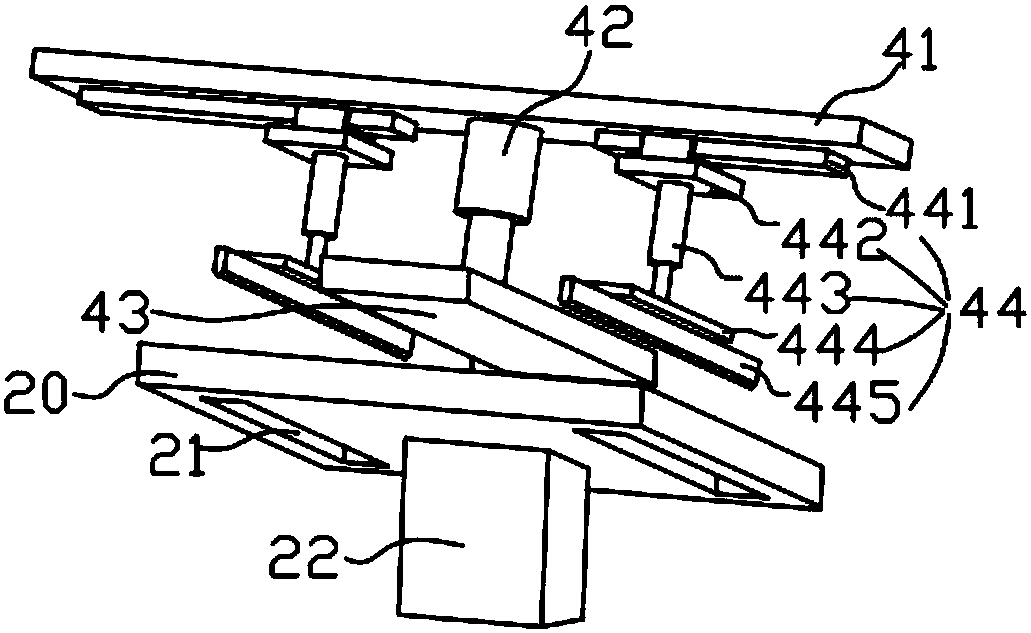

[0022] Such as Figure 1 to Figure 3 As shown, the present invention provides a soaking type peeling device, comprising: a frame 10; a carrier plate 20 arranged obliquely on the frame 10 through a column 22; The vacuum adsorption plate 30 on the edge; a cutting unit 40 installed directly above the carrying plate 20; a pair of limiting units 50 set through the carrying plate 20, and the carrying plate 20 is formed for the limit The tank body 21 through which the bit unit 50 penetrates; a water tank unit 60 located on one side of the carrying plate 20 for receiving the cut corn ears conveyed through the carrying plate 20; and a water tank unit 60 arranged on the water tank unit 60 The fan unit 70 directly above is used to absorb the dried bracts; the limiting unit 50 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com