A device and method for rapid sampling of soil layers

A technology of soil stratification and sampling device, applied in the direction of sampling device, can solve the problems of reducing sampling efficiency, wasting labor, wasting time, etc., and achieving the effect of increasing the scope of sampling, increasing the scope, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

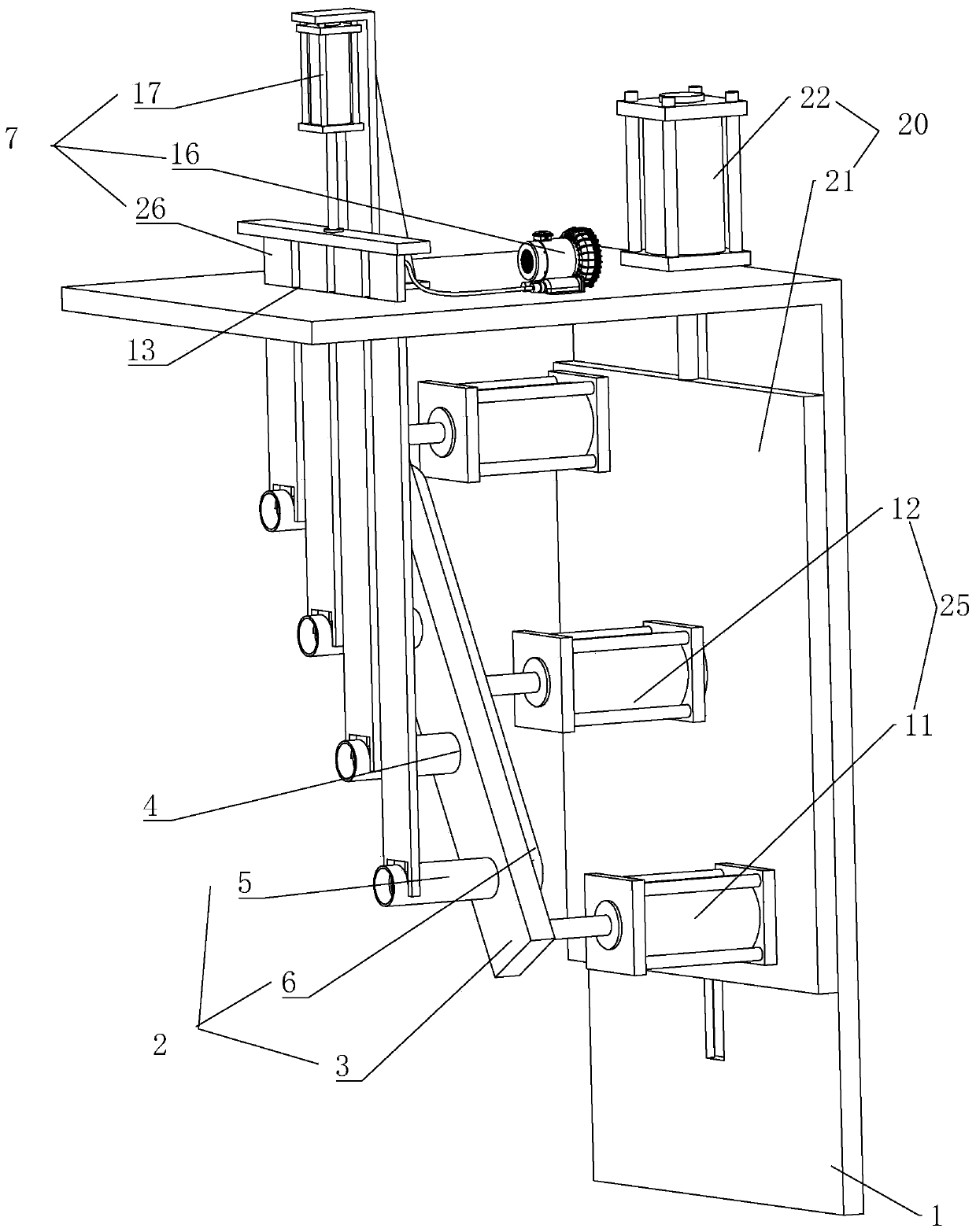

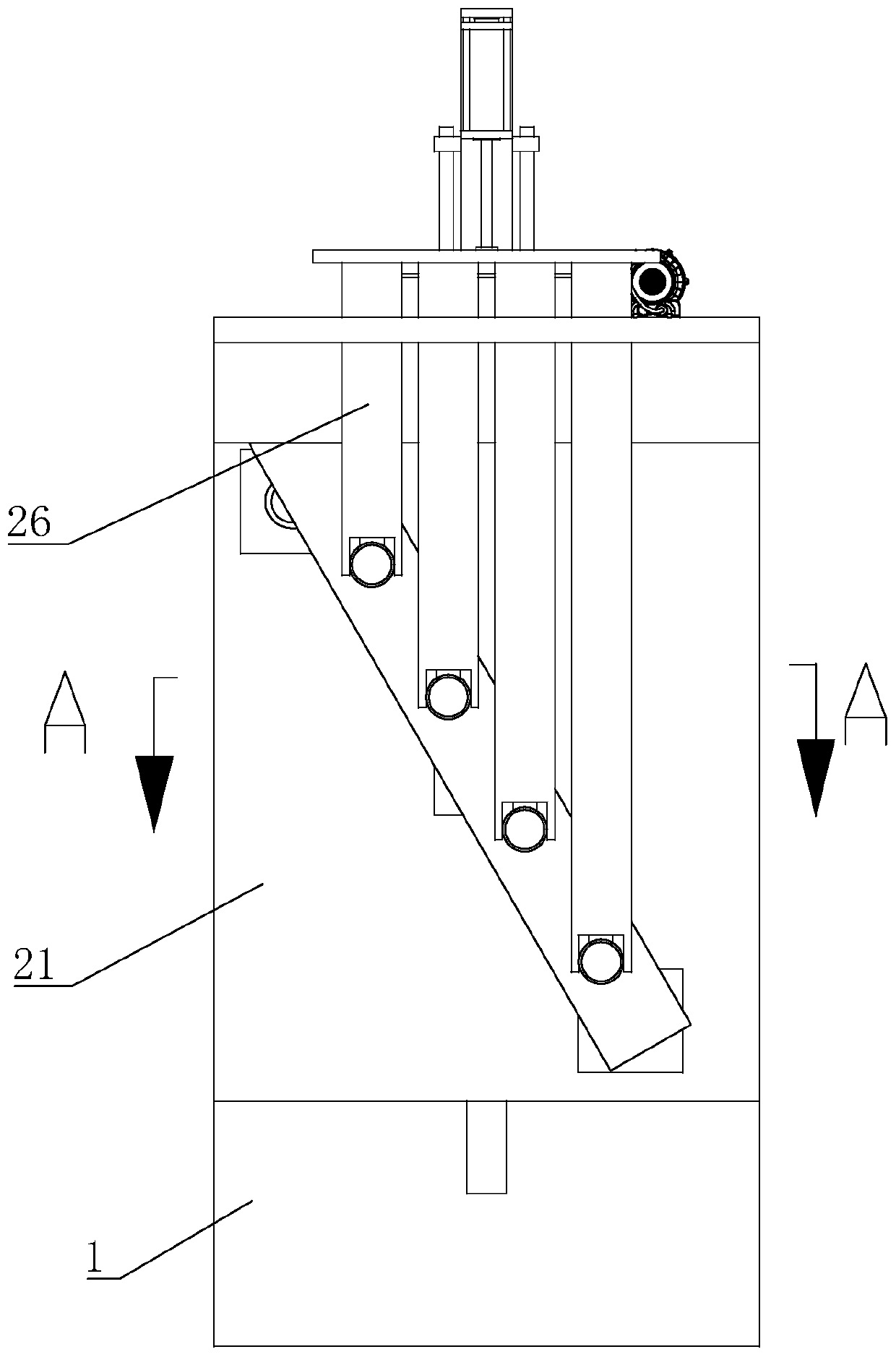

[0037] Embodiment one: a kind of quick sampling device for stratification of soil, such as figure 1 As shown, it includes a bracket 1 on which a sampling assembly 2 for sampling and a driving mechanism 25 fixedly connected to the bracket 1 for driving the sampling assembly 2 are installed.

[0038] like figure 1 As shown, the sampling assembly 2 includes a mounting plate 3 that is slidably connected to the support 1, and a number of mounting holes 4 are equally spaced along the length direction of the mounting plate 3, and a sampling ring 5 is slidably connected to the mounting holes 4. A baffle 6 is fixedly connected to the end of the ring 5 near the support 1; the mounting plate 3 and the baffle 6 are inclined to the horizontal plane, so that each sampling ring 5 does not interfere with each other in the vertical direction, and each sampling ring 5 The height difference between them is 10 centimeters, and the center of the top sampling ring 5 is 10 centimeters away from the...

Embodiment 2

[0051] Embodiment two: the specific steps of a kind of method for layered quick sampling of soil are as follows:

[0052] Step 1: Fix the sampling ring 5 on the baffle 6, and place the sampling ring 5 in the mounting hole 4;

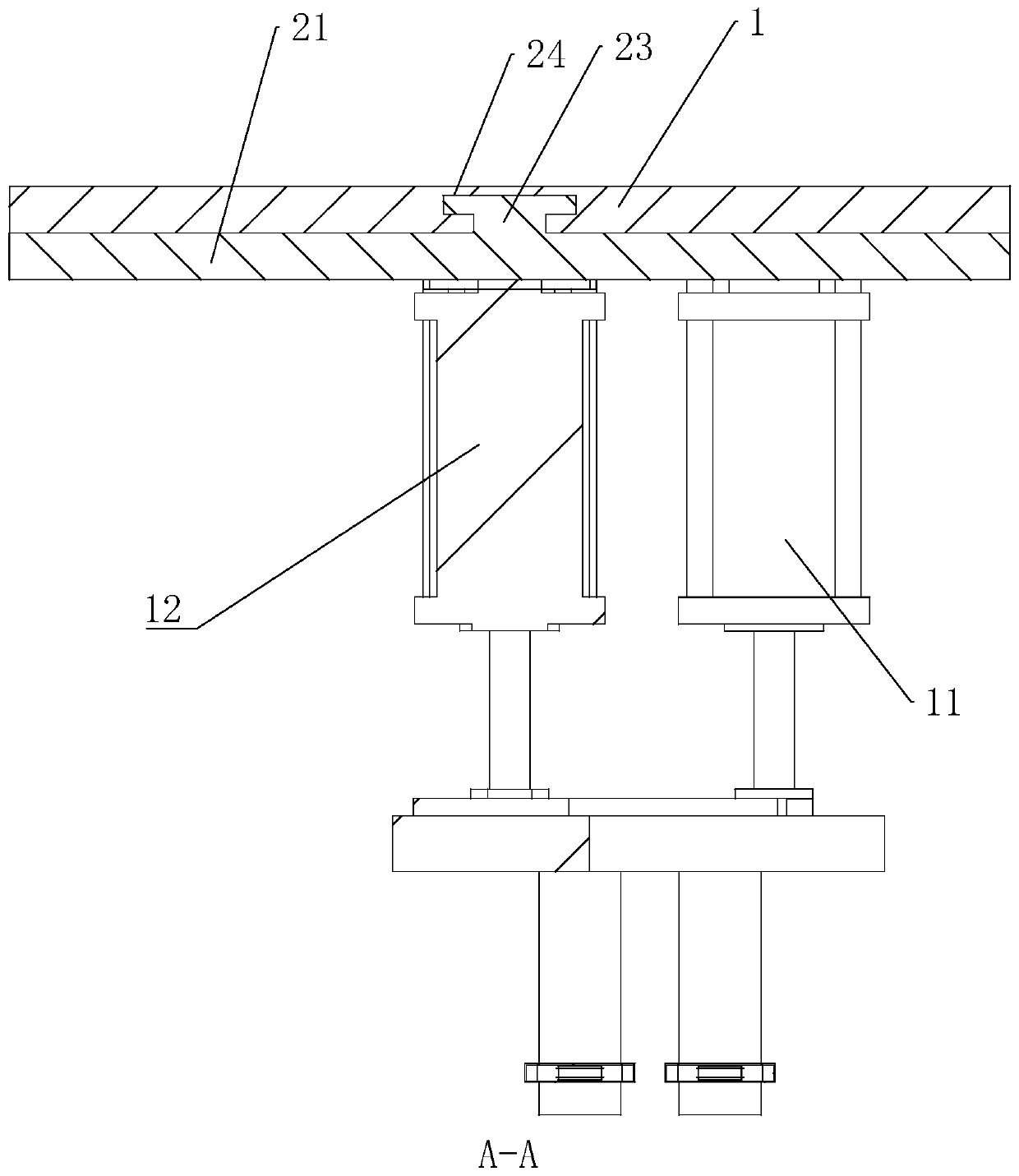

[0053] Step 2: start the drive cylinder, and adjust the height of the bottom plate 21 according to the needs of the test;

[0054] Step 3: Start the first driving cylinder 11, press the mounting plate 3 against the soil surface, start the second driving cylinder 12 to fully insert the sampling ring 5 into the soil;

[0055] Step 4: Start the air pump 16, attach the stopper 8 to the slot 14 at the lower end of the drive plate 26, start the third drive cylinder 17, and insert the drive plate 26 from above to insert the stopper 8 into the soil until the stopper 8 moves To the arc-shaped port 9 of the corresponding sampling loop 5, turn off the air pump 16, start the third drive cylinder 17 to take out the drive plate 26;

[0056] Step 5: Start the first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com