Mine draw shaft system

A technology for shafts and mines, which is applied in the field of mining engineering, and can solve problems such as increased project investment costs and increased vein-piercing projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

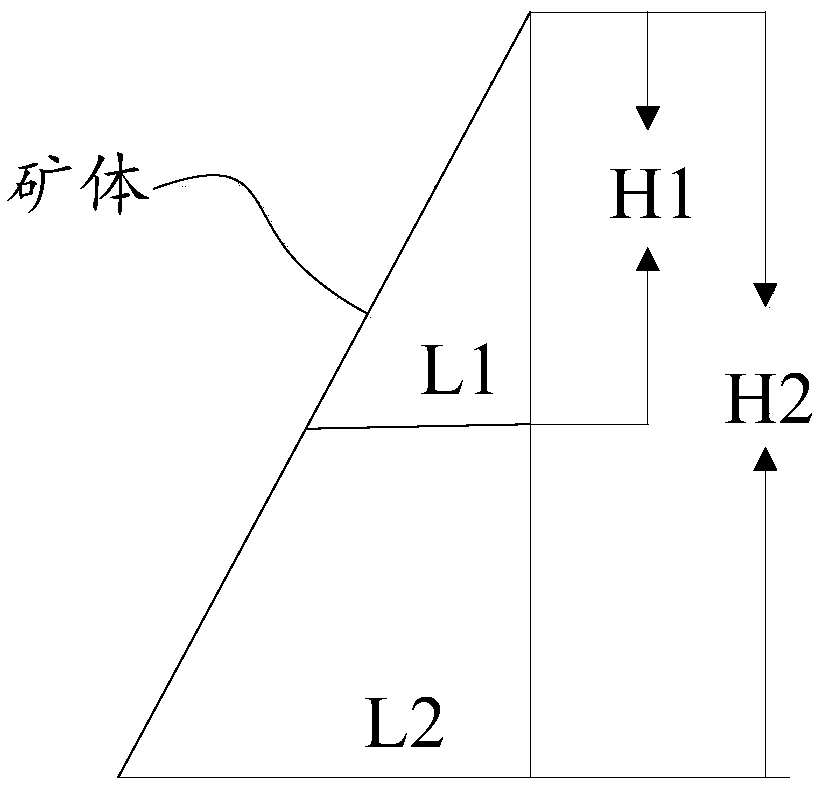

[0027] This embodiment provides a mine shaft system, such as figure 2 As shown, the chute system includes: feeding conveying channel 1, screening equipment 2, first chute 3, second chute 4 and discharge conveying channel 5;

[0028] The feeding conveying channel 1 is connected to one end of the first chute 3; one end of the first chute 3 is the inlet end of the first chute 3; the screening equipment 2 is installed at one end of the first chute 3; The other end of the first chute 3 is connected with one end of the second chute 4; the discharge conveying channel 5 is located below the other end of the second chute, and is used for utilizing the rail mine car to transport the ore; in order to reduce the distance through the veins, the The first chute 3 is an inclined chute; in order to effectively form the center falling ore and reduce the wear of the second chute, the second chute 4 is a straight chute.

[0029] Here, the inclination angle of the first chute 3 includes: 65° to...

Embodiment 2

[0038] In practical application, when using the chute system provided in Embodiment 1 to transport mineral materials to a certain mine, the specific implementation is as follows:

[0039] same as figure 2 As shown, the chute system includes: feeding conveying channel 1, screening equipment 2, first chute 3, second chute 4 and discharge conveying channel 5;

[0040] The feeding conveying channel 1 is connected to one end of the first chute 3; one end of the first chute 3 is the inlet end of the first chute 3; the screening equipment 2 is installed at one end of the first chute 3; The other end of the first chute 3 is connected with one end of the second chute 4; the discharge conveying channel 5 is located below the other end of the second chute, and is used for utilizing the rail mine car to transport the ore; in order to reduce the distance through the veins, the The first chute 3 is an inclined chute; in order to effectively form the center falling ore and reduce the wear ...

Embodiment 3

[0050] In practical application, when using the chute system provided in Embodiment 1 to transport mineral materials to another mine, the specific implementation is as follows:

[0051] same as figure 2 As shown, the chute system includes: feeding conveying channel 1, screening equipment 2, first chute 3, second chute 4 and discharge conveying channel 5;

[0052] The feeding conveying channel 1 is connected to one end of the first chute 3; one end of the first chute 3 is the inlet end of the first chute 3; the screening equipment 2 is installed at one end of the first chute 3; The other end of the first chute 3 is connected with one end of the second chute 4; the discharge conveying channel 5 is located below the other end of the second chute, and is used for utilizing the rail mine car to transport the ore; in order to reduce the distance through the veins, the The first chute 3 is an inclined chute; in order to effectively form the center falling ore and reduce the wear of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com