Self-adaptation deviation adjusting device of tubular belt conveyor

A tubular belt type, self-adaptive technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of labor, conveyor belt deviation, uneven conveyor belt pressure, etc., to achieve easy use and maintenance, high reliability , the effect of flexible automatic offset adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

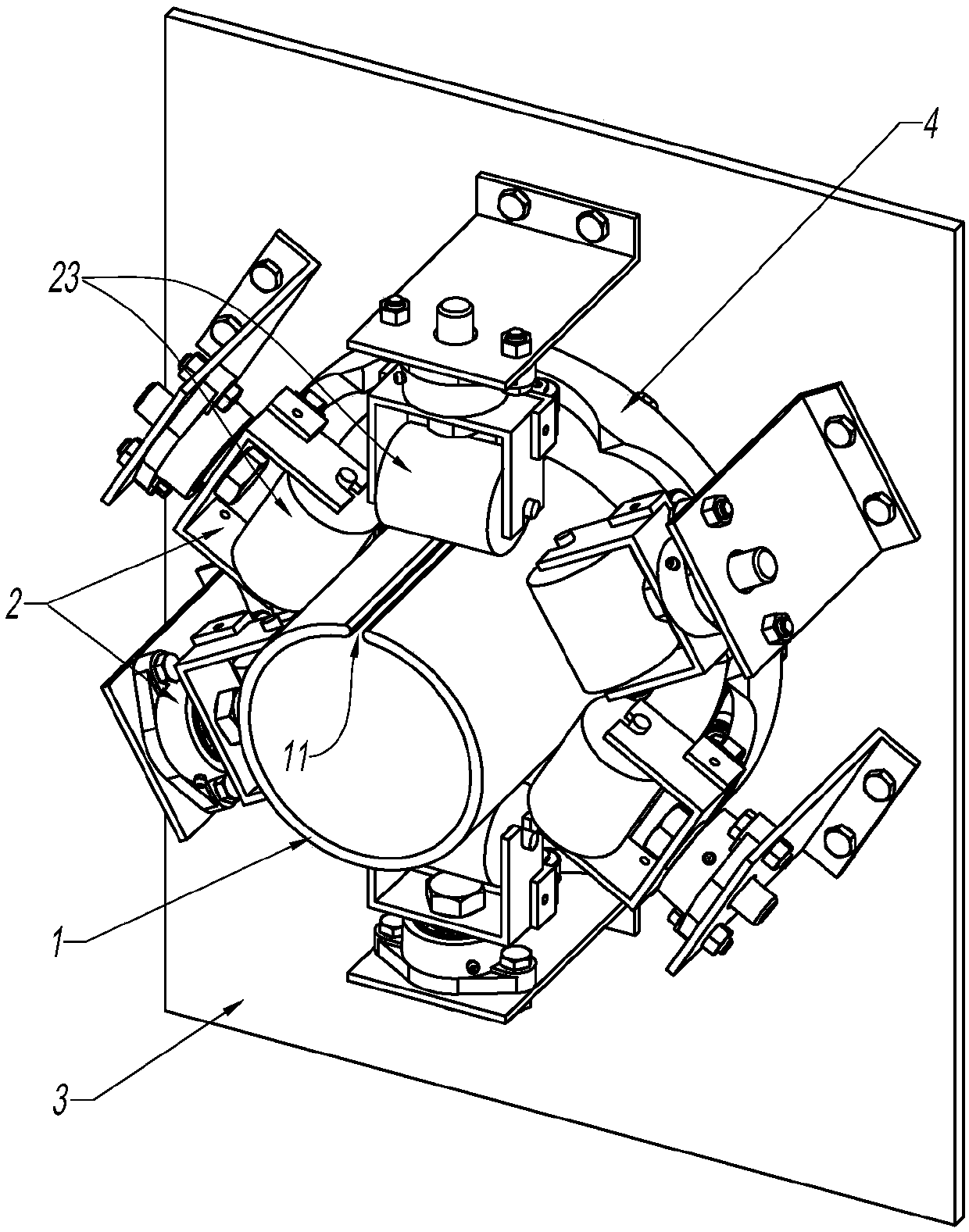

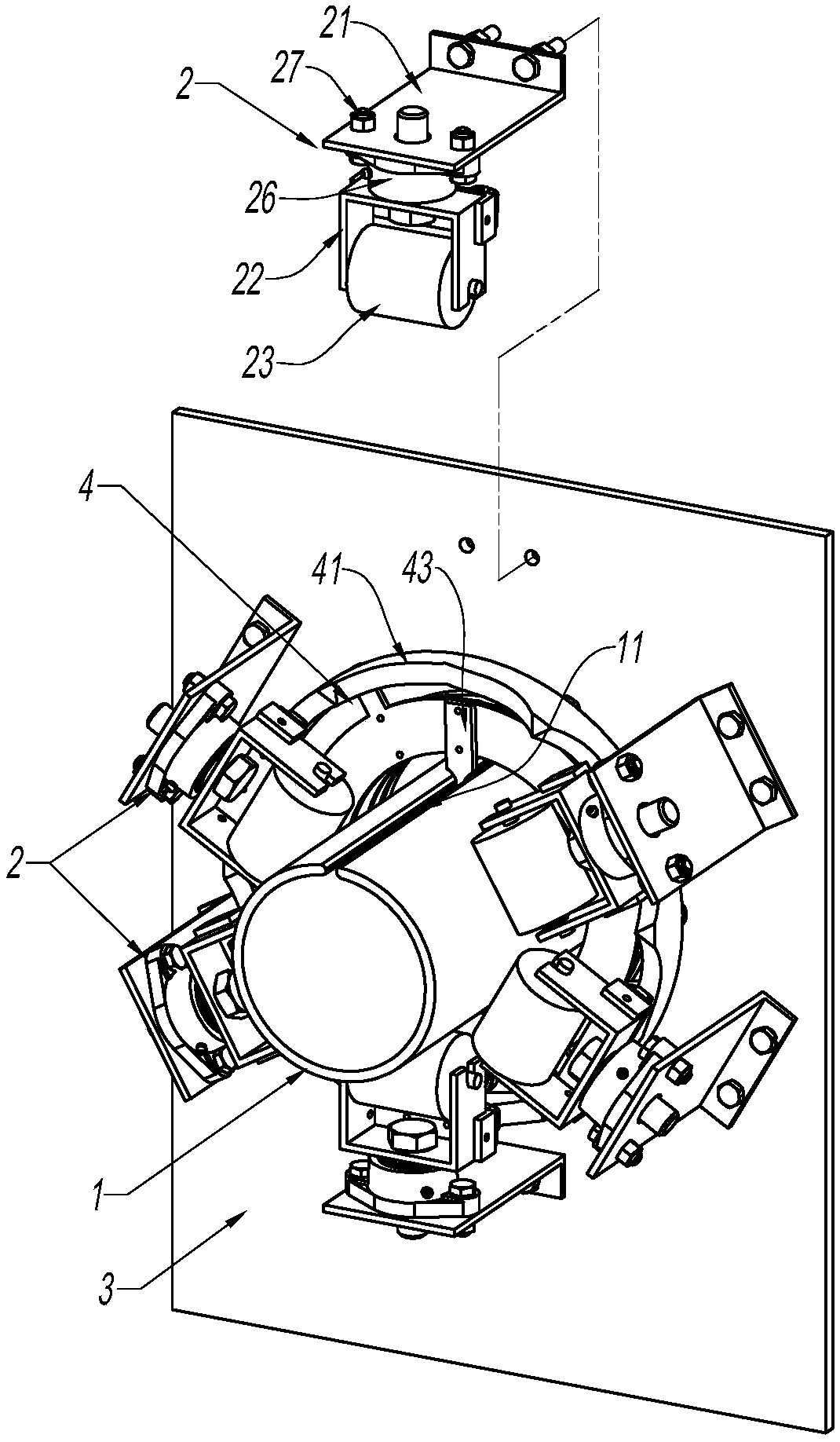

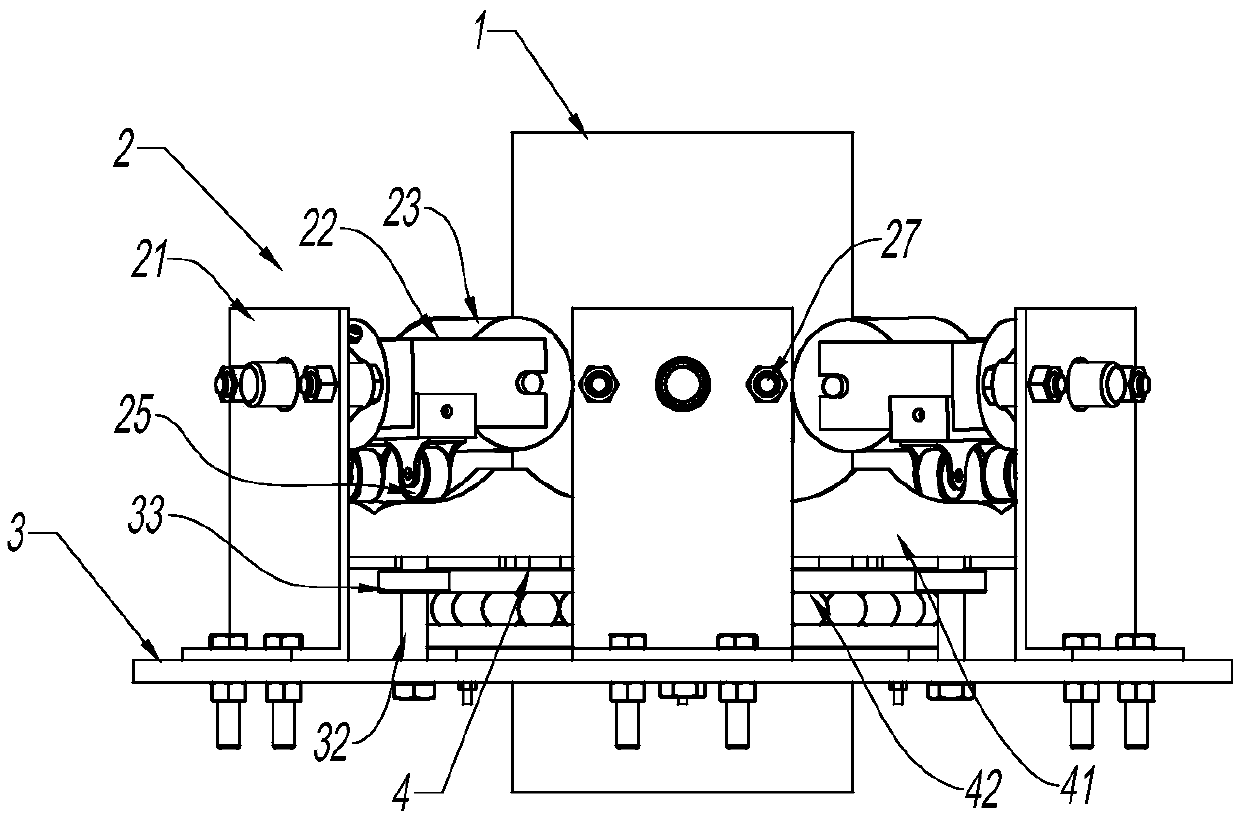

[0025] refer to Figure 1 to Figure 6 , an adaptive deviation adjustment device for a tubular belt conveyor, including a conveyor belt 1, an idler roller assembly 2, a support plate 3 and an adaptive deviation adjustment mechanism 4; a plurality of idler roller assemblies 2 are evenly distributed outside the round window 31 of the support plate 3 On the circumference, they form a support for the conveyor belt 1 in circular segments.

[0026] The roller assembly 2 includes a base 21, a roller frame 22, a roller 23, a bearing 24 and a contact wheel 25; the roller 23 is axially positioned on the roller frame 22, and the roller frame 22 is positioned on the base 21 through the bearing 24, so that the roller 23 can rotate freely relative to the base 21; the contact wheel 25 is locked on the side of the roller frame 22 towards the support plate 3, more specifically, a pair of contact wheels 25 are provided, and the two contact wheels 25 are symmetrically distributed on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com