Roller lever actuating device and roller lever valve equipped therewith

A lever control and lever valve technology, applied in mechanical equipment, valve operation/release devices, valve details, etc., can solve the problems of roller lever damage, roller lever high bending load, etc., to reduce internal stress, large spring length, The effect of compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

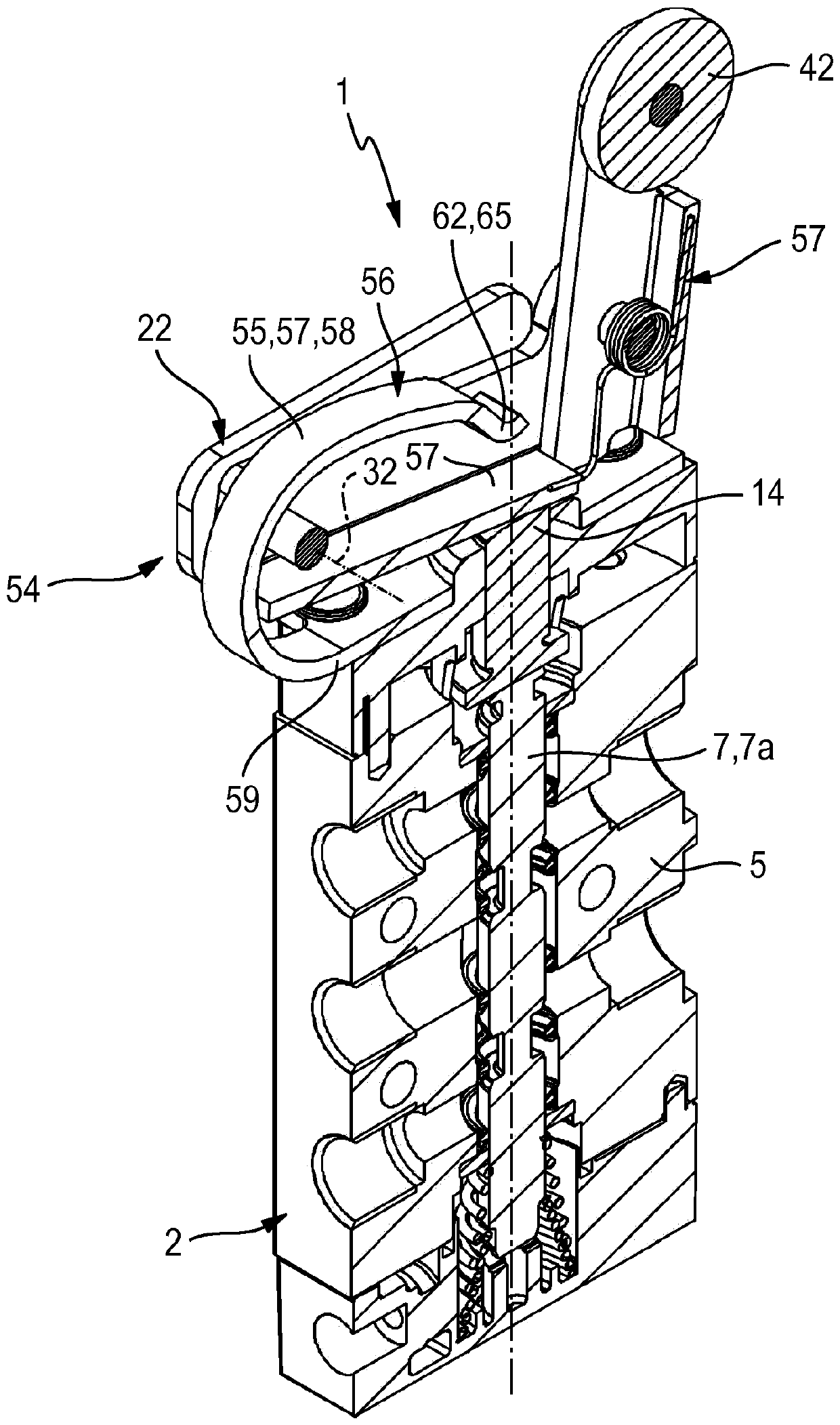

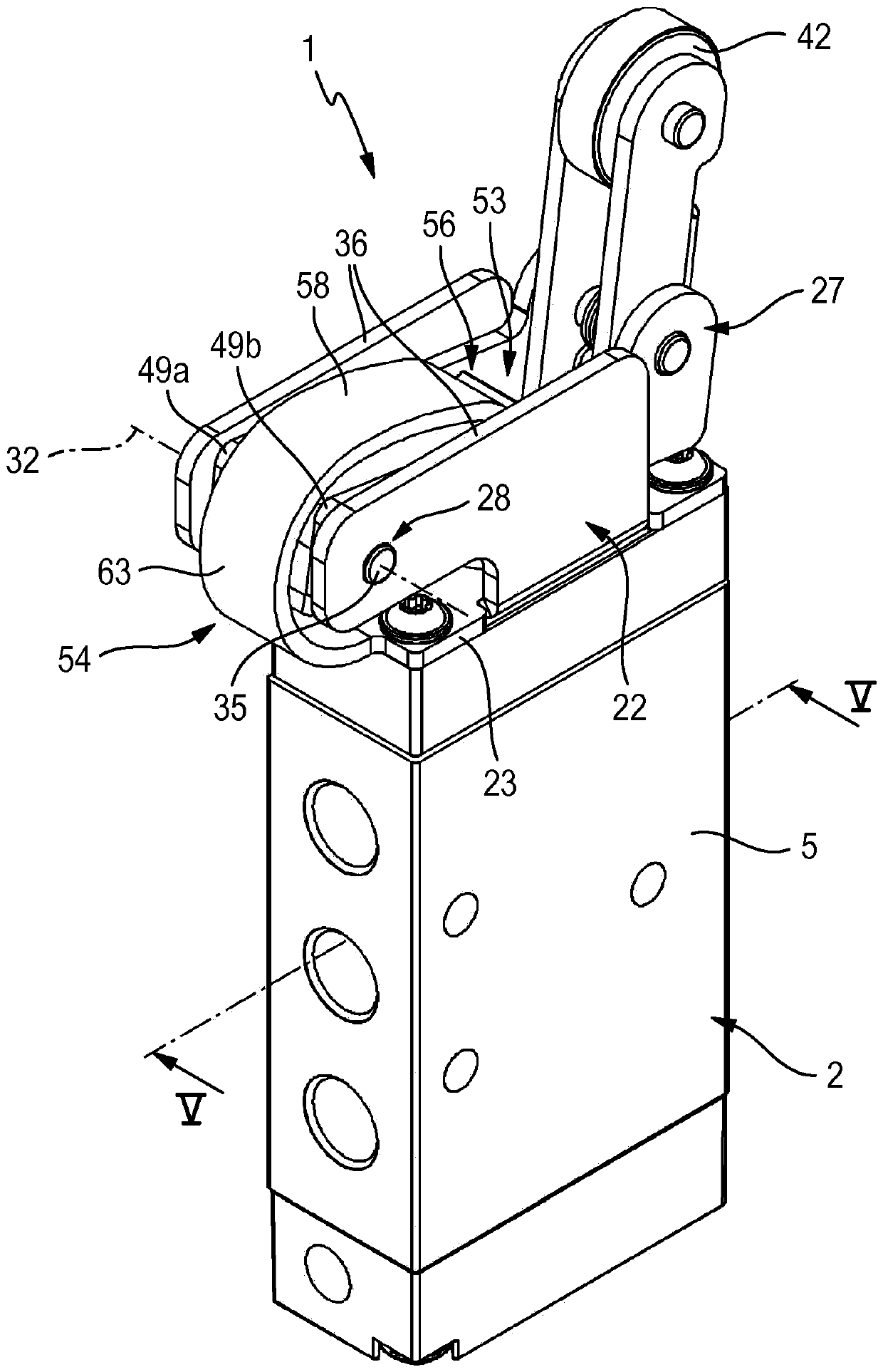

[0028] The roller lever valve 1 shown in the drawing has a valve unit 2 and a roller lever actuating device 3 for mechanically actuating the valve unit 2 .

[0029] The valve unit 2 has a longitudinal axis 4 . The roller lever actuation device 3 is preferably arranged on one of the two axial end sides of the valve unit 2 .

[0030] The valve unit 2 has a one-piece or multi-piece valve housing 5 , in which a valve chamber 6 is formed, in which a valve ring assembly 7 extends. In the present exemplary embodiment, the valve segment assembly 7 consists of a single valve segment 7a, but it can also comprise a plurality of valve segments. Within the range of the switching movement 8 indicated by the double arrow, the valve ring assembly 7 can be moved relative to the valve housing 5 in the axial direction of the longitudinal axis 4 and thus be switched between two switching positions. exist figure 2 and 3 In the first switching position of the valve link assembly 7 shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com