Construction method of transfer layer bailey frame platform of high-rise building

A technology of high-rise buildings and construction methods, which is applied in the fields of construction, building structure, and building materials, and can solve problems such as potential safety hazards, poor stress, and difficulty in maintaining stability, so as to ensure quality, construction safety, and platform stability Reliable, load-bearing shape ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The transfer floor of the high-rise building of this embodiment is located above the ninth floor, with a mezzanine on one side and no mezzanine on the other side. The construction method of the Bailey platform platform is as shown in the figure, and it is constructed according to the following steps:

[0029] The first step, install the lattice column - such as figure 1 As shown, the lattice columns 1 distributed at intervals are respectively installed by pre-embedded anchor bolts 1-3 on both sides of the lattice column foundation 1-2 that is integrated with the building foundation 1-1 at the position below the girder of the transfer floor, The lattice column 1 of this embodiment adopts the standard tower sections 1-4 of the tower crane to be spliced section by section from bottom to top;

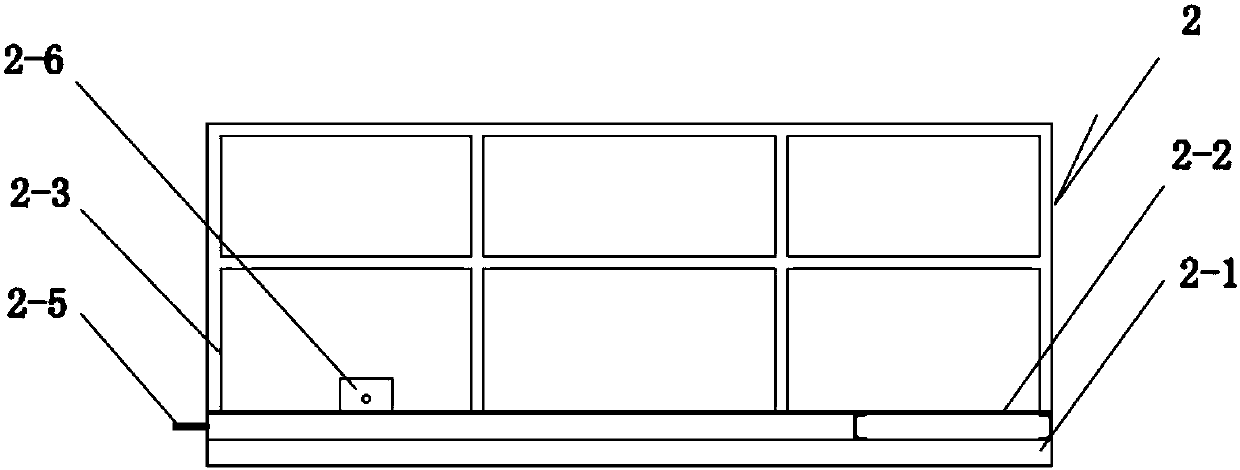

[0030] When splicing installation, use Figure 2.1 , Figure 2.2 , Figure 2.3 The tool-type operating platform 2 shown has a "concave"-shaped table top frame 2-1 welded by chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com