Universal-joint crossing shaft

A universal joint and cross shaft technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of large resistance and large flow of lubricating oil, and achieve extended service life, increased lubrication effect, The effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

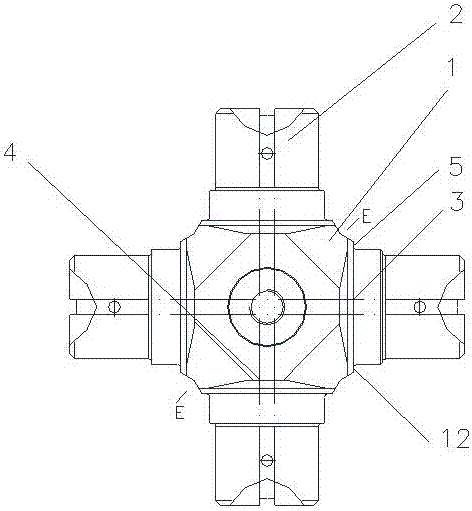

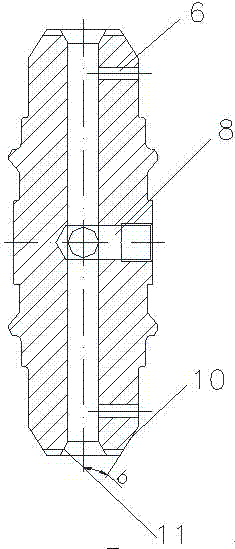

[0026] Embodiment 1: a kind of universal joint cross shaft provided by the present invention comprises: a cross-shaped universal joint base body 1, and four ends of the universal joint base body have ends 2; the inside of the universal joint base body It also has a longitudinal oil passage 3 and a transverse oil passage 4, the longitudinal oil passage runs through the center of the universal joint base body and a pair of ends in the longitudinal direction of the universal joint base body; the transverse oil passage runs through the universal joint The central part of the base body and a pair of lateral ends of the universal joint base body; the ends are also provided with radial oil holes 6, and the oil holes communicate with the longitudinal oil passage or the transverse oil passage.

Embodiment 2

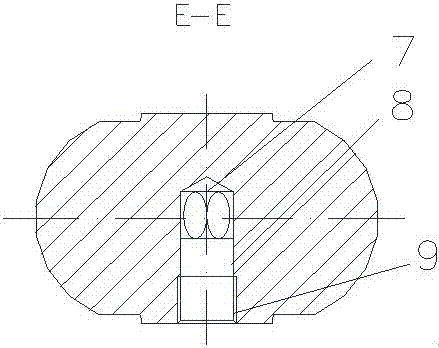

[0027] Embodiment 2: as figure 1 , 2 , shown in 3; a kind of universal joint cross shaft provided by the present invention includes: a cross-shaped universal joint base, four ends of the universal joint base all have ends; the inside of the universal joint base is also It has a longitudinal oil passage and a transverse oil passage, the longitudinal oil passage passes through the center of the universal joint base and a pair of ends in the longitudinal direction of the universal joint base; the transverse oil passage passes through the center of the universal joint base The position and a pair of ends transverse to the base body of the universal joint; radial oil holes are also provided on the ends, and the oil holes communicate with the longitudinal oil passage or the transverse oil passage.

[0028] The longitudinal oil passages and the transverse oil passages are cross-connected with each other. Wherein the connecting portion where the longitudinal oil passage and the tran...

Embodiment 3

[0030] Embodiment 3: as Figure 4 , Figure 5 As shown, a kind of universal joint cross shaft provided by the present invention includes: a cross-shaped universal joint base, and the four ends of the universal joint base all have ends; the inside of the universal joint base also has longitudinal An oil passage and a transverse oil passage, the longitudinal oil passage runs through the center of the universal joint base body and a pair of ends in the longitudinal direction of the universal joint base body; the transverse oil passage runs through the center part of the universal joint base body and A pair of ends transverse to the base body of the universal joint; radial oil holes are also provided on the ends, and the oil holes communicate with the longitudinal oil passage or the transverse oil passage; the longitudinal oil passage or the transverse oil passage The part of the oil passage and the oil passage hole is partially provided with a smooth curved outer convex part 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com