Assisted bike driving system and application thereof

A technology for power-assisted bicycles and driving systems, which is applied in the directions of rider driving, vehicle components, vehicle gearboxes, etc., which can solve the problems of power consumption and riding effort, and achieve the effect of light travel and increased travel use probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

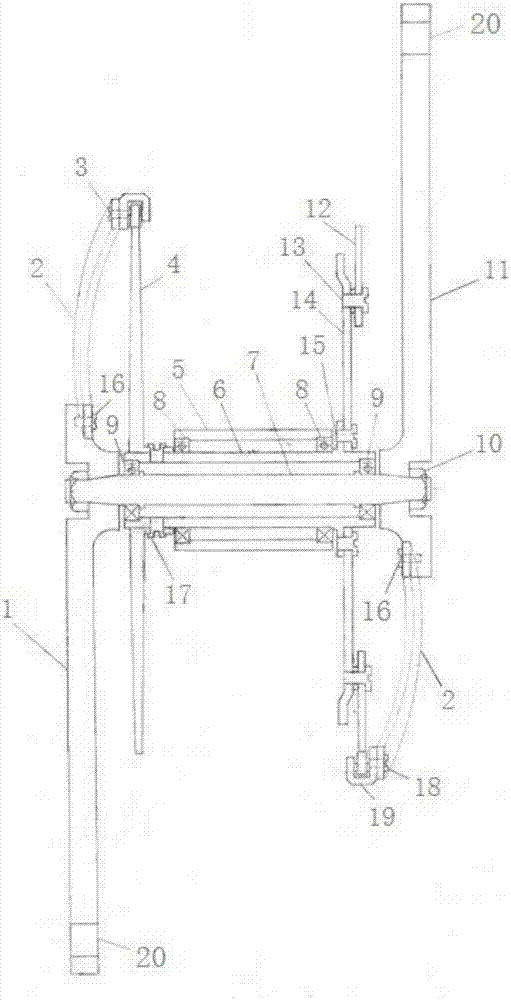

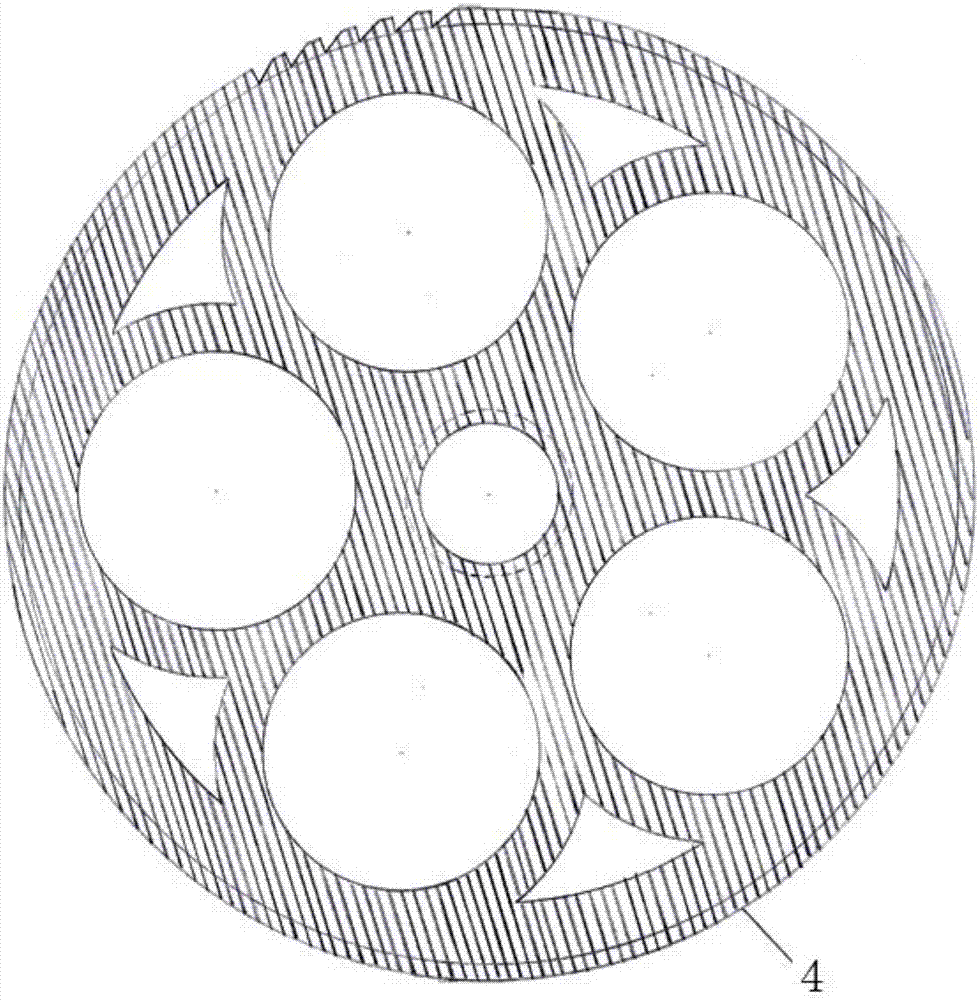

[0049] Such as figure 1As shown, this embodiment provides a power-assisted bicycle drive system, including a crank and a crank shaft 7, a transmission shaft 6, and a fixed shaft 5 that are sequentially fitted from the inside to the outside; Fixedly connected with the driven chain toothed disc 14, the outer circle of the driven chain toothed disc 14 is also connected with the driving gear ring 12; the two ends of the crank shaft 7 are respectively fixedly connected with two described cranks, and one end of the crank is connected with the pedal, The other end is connected with a lever power transmission, one end of one lever power transmission drives the outer circle of the active chainring to rotate through a ratchet driver and a pawl, and one end of the other lever power transmission is driven by a ratchet driver and a pawl The outer circle of the driving gear ring rotates.

[0050] Specifically, as Figure 9 As shown, the two ends of the crankshaft 7 are installed with two ...

Embodiment 2

[0055] This embodiment provides a power-assisted bicycle driving system, the structure of which is as described in Embodiment 1, the difference is that: one end of the left lever power transmitter 2 and the extended end of the crank 1 form a 45° inclined angle and are fixed by Screw connection, the other end is driven by the ratchet drive and the pawl to drive the outer circle of the active toothed plate 4 to rotate; one end of the lever power transmission device 2 on the right is at a 45° inclined angle with the extended end of the crank and is connected by a set screw, the other end The outer circle of the active gear ring 12 is driven to rotate by the ratchet driver and the pawl.

[0056] The semicircular lever power transmitter is in the shape of an arc semicircle, the arc radius is 36-93mm, and the rotation radius is 39-135mm. The semicircular lever power transmitter and the crank are inclined at an angle of about 45 degrees to save labor. The ratchet drive It is U-shaped...

Embodiment 3

[0060] This embodiment provides a power-assisted bicycle driving system, which is basically the same in structure as Embodiment 1, but cancels the driving chainring 4, the driving ring 12, the ratchet driver 19 and the pawl, including the crank and the sequential assembly from the inside to the outside. crank shaft, transmission shaft, fixed shaft; one end of the transmission shaft is fixedly connected with the chainring of the driven chain; One end of one lever power transmitter is fixedly connected with the other end of the drive shaft, and one end of the other lever power transmitter is fixedly connected with the toothed plate of the driven chain.

[0061] Specifically, the two ends of the crankshaft 7 are respectively equipped with two cranks, i.e., the left crank 1 and the right crank 11, by fixing screws 10. Both the left crank 1 and the right crank 11 have pedal mounting holes 20, Easy to install pedals. Between the crankshaft 7 and the transmission shaft 6 , between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com