Ink supply device for offset press and ink supply control method

A technology of ink supply device and offset printing machine, which is applied to the general parts of printing machinery, printing machines, printing, etc., which can solve the problems of absolute accuracy and relative accuracy not being guaranteed, difficulty in calculating, adjusting and controlling ink supply, and accurate calibration Control big problems, achieve the effect of shortening auxiliary time, easy to achieve vivid colors, high degree of automation and digitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

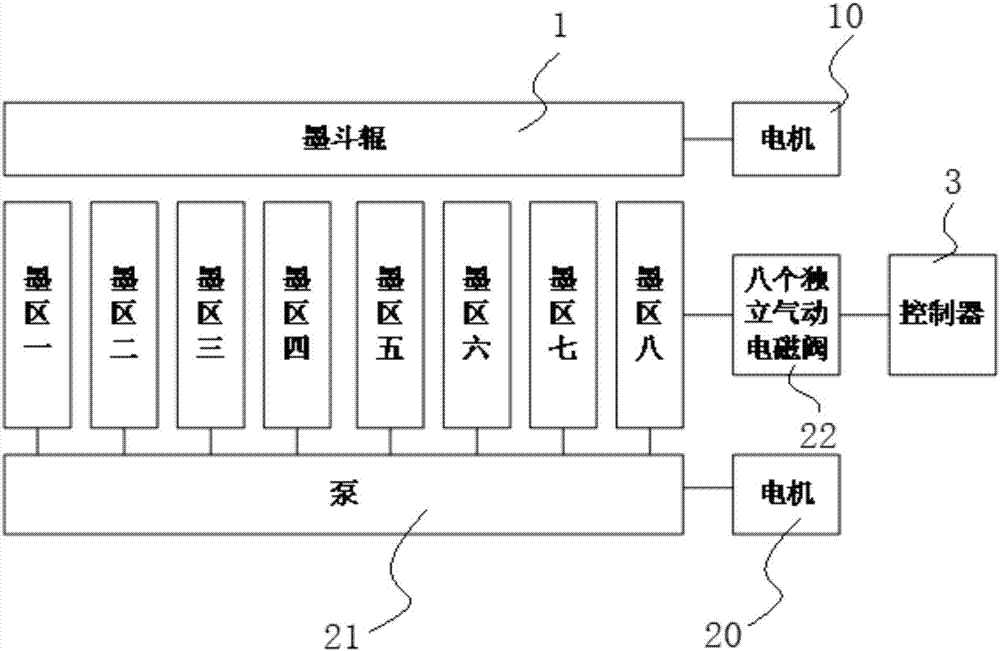

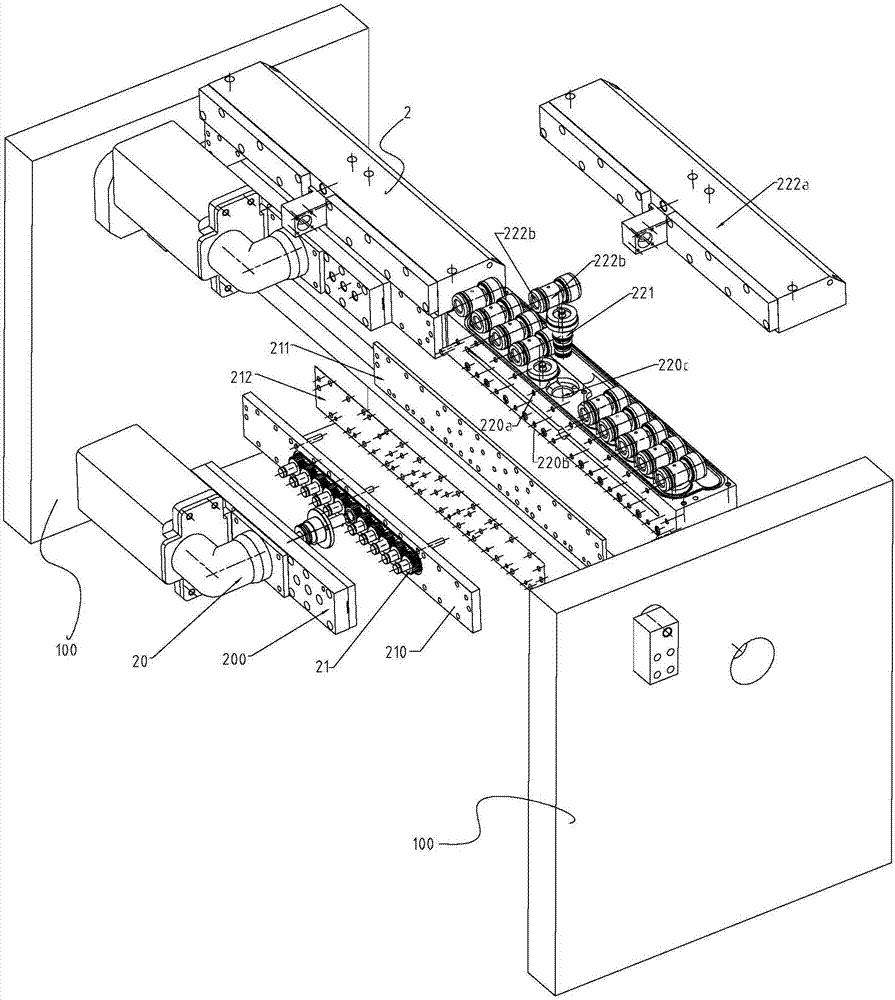

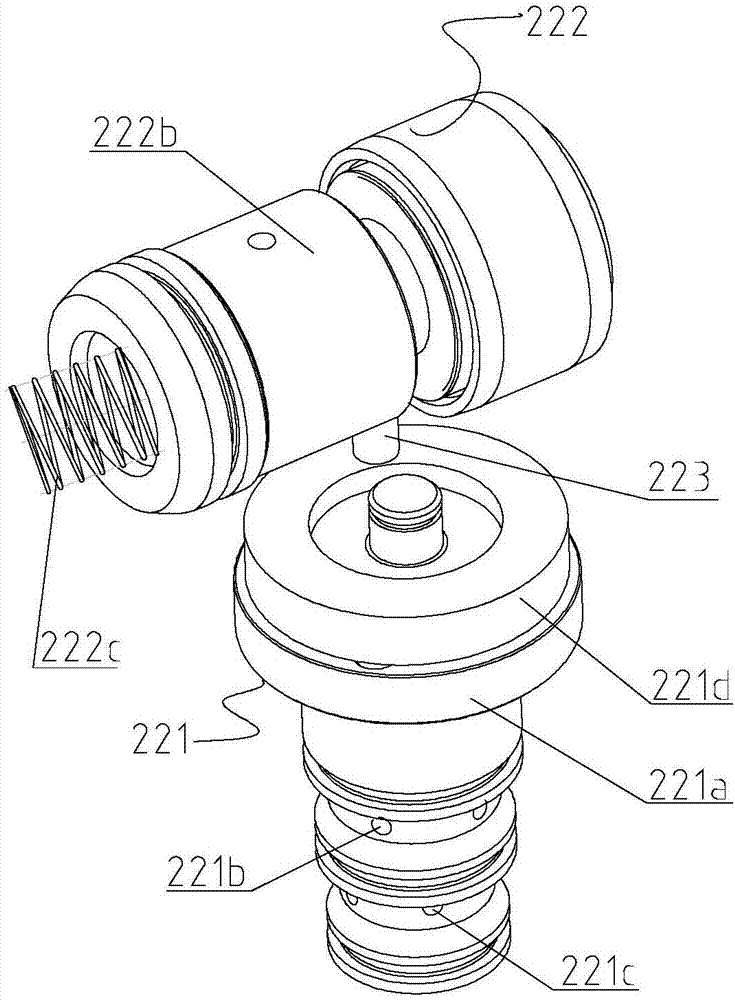

[0040] see Figure 1 to Figure 4, the ink supply device of the offset printing machine of the present invention includes an ink fountain roller 1, a digital ink fountain 2 and an ink storage tank (not shown in the figure). Each digital ink fountain 2 corresponds to eight ink fountains on the printed sheet format; two ink fountains should be arranged if sixteen ink fountains are needed, and three digital ink fountains should be set in twenty-four ink districts, and by analogy, the present embodiment uses two ink fountains. The digital ink fountain illustrates the technical scheme of the present invention.

[0041] The ink fountain roller 1 straddles a pair of main wallboards 100 of the printing press and is driven to rotate by the ink fountain roller motor 10;

[0042] Two digital ink fountains 2 are installed on the main wallboard 100 and located above the ink fountain ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com