Multi-camera array shooting device with adjustable spacing

A shooting device and multi-camera technology, applied in the field of 3D shooting, can solve the problems of large shooting limitations, high cost, and long cycle, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

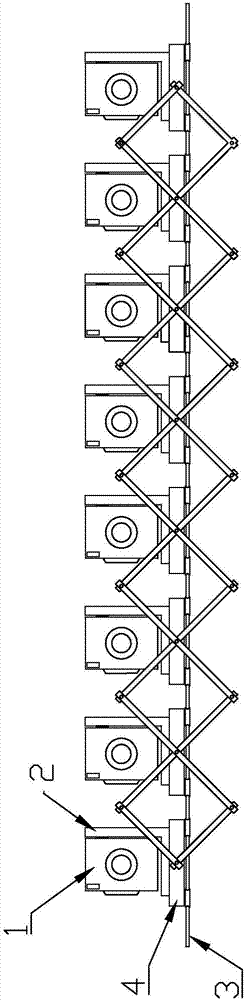

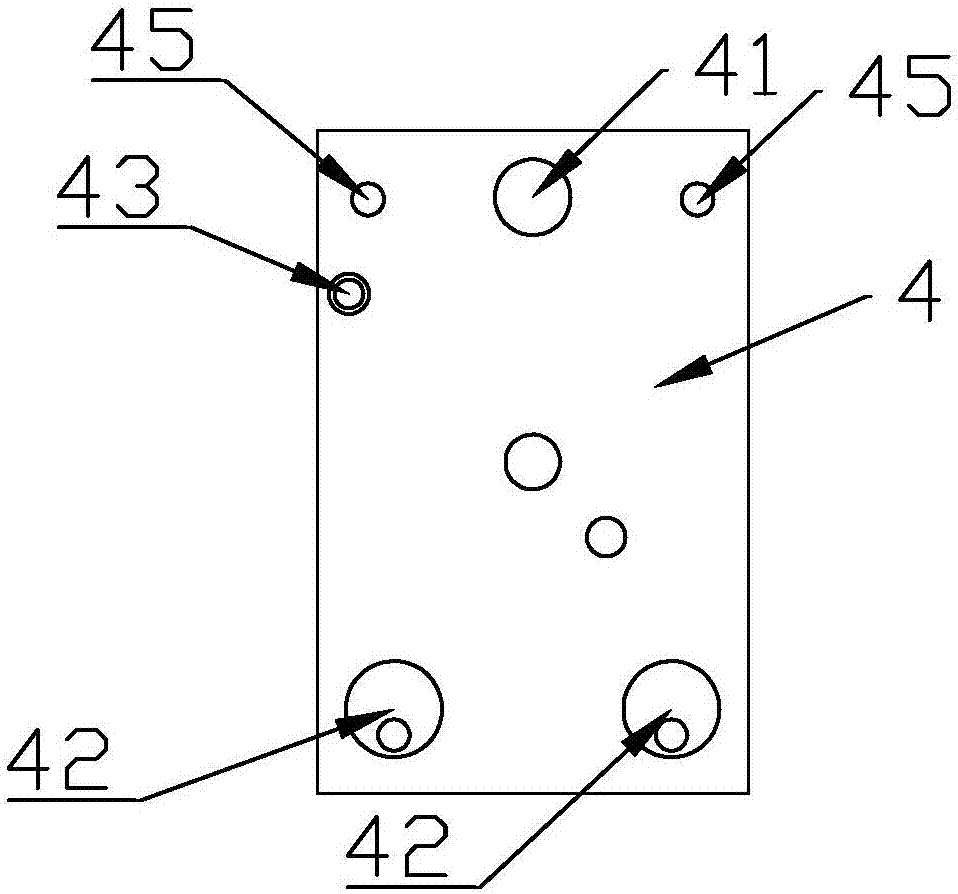

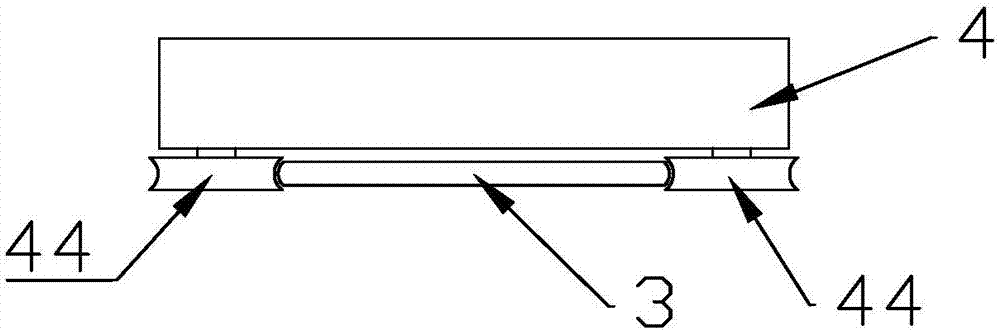

[0017] Combine below Figure 1 to Figure 3 The present invention is described further.

[0018] The multi-camera array photographing device with adjustable spacing includes multiple cameras 1, and the number of cameras 1 in this embodiment is eight. Each of the cameras 1 is directly or indirectly arranged on the guide rail 3 through a corresponding slider 4 , and each of the sliders 4 is arranged in series along the guide rail 3 in sequence. The camera 1 can be directly installed on the slider 4 , or the camera 1 can be installed on the L-shaped mounting plate 2 , and then the L-shaped mounting plate 2 can be fixed on the slider 4 . In this embodiment, the installation method of the camera is the latter. The guide rail 3 is installed on the square tube aluminum profile. To strengthen the rigidity of the guide rail, it can be fastened to the square tube aluminum profile by multiple screws. When using the multi-camera array shooting device, the square tube aluminum profile can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com