Automatic descaling and sealing device of pull rod of short-stress rolling mill

A short stress rolling mill and sealing device technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of unusable, damaged and aging seals, and increase the friction torque of protective sleeves, so as to achieve convenient manufacturing and use, Not easy to deposit dirt, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

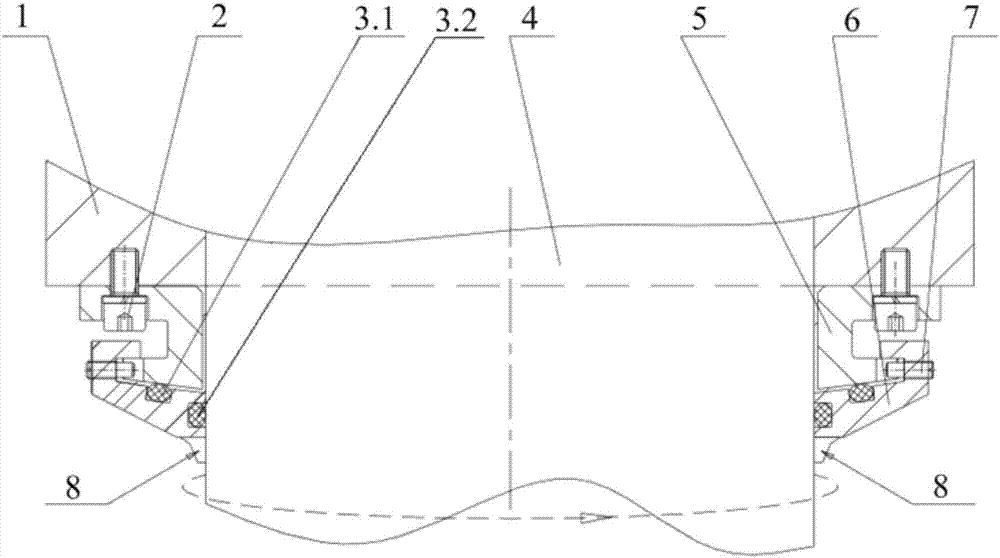

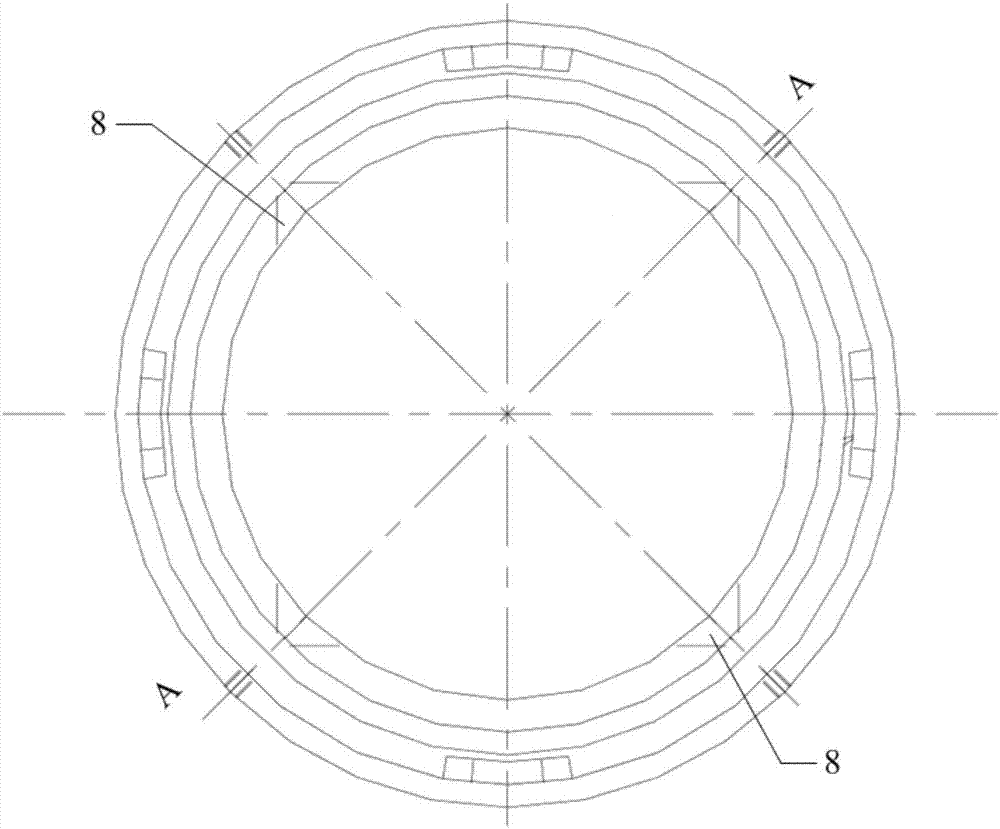

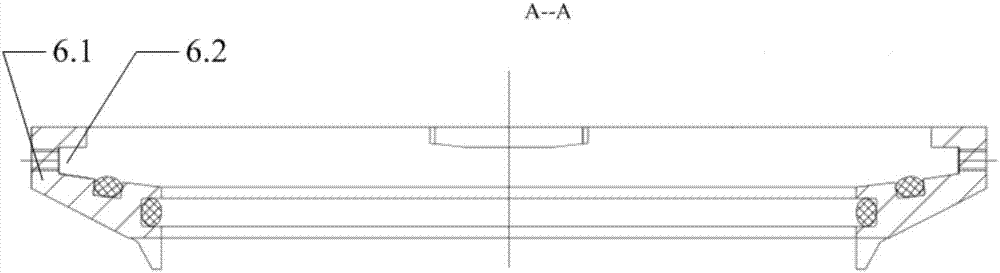

[0040] see Figure 1-5 , a self-cleaning sealing device for a short-stress rolling mill pull rod, characterized in that it includes a sealing base 5 and a sealing cover 6; the sealing base 5 is ring-shaped, and the sealing base 5 is provided with a The first fixing device; the sealing end surface of the sealing cover 6 and the sealing base 5 used for sealing is a conical surface or a spherical surface, and the sealing end surface of the sealing cover 6 is provided with a first sealing ring 3.1; the inner ring surface of the sealing cover 6 is provided with There is a second seal ring 3.2; the outer end surface of the seal cover 6 is provided with at least one set of scrapers 8 for scraping off the dirt on the pull rod of the rolling mill; the seal base 5 and the seal cover 6 are provided with a seal base 5 and a seal cover 6 the second fixture.

[0041] The first fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com