Welding holder capable of automatically exchanging cores

A welding handle and automatic technology, applied in welding accessories, electrode characteristics, electrode support devices, etc., can solve the problems of low actual load duration of equipment, small selection range of welding process parameters, and limited productivity, so as to improve production efficiency and welding. Quality, improvement effect, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

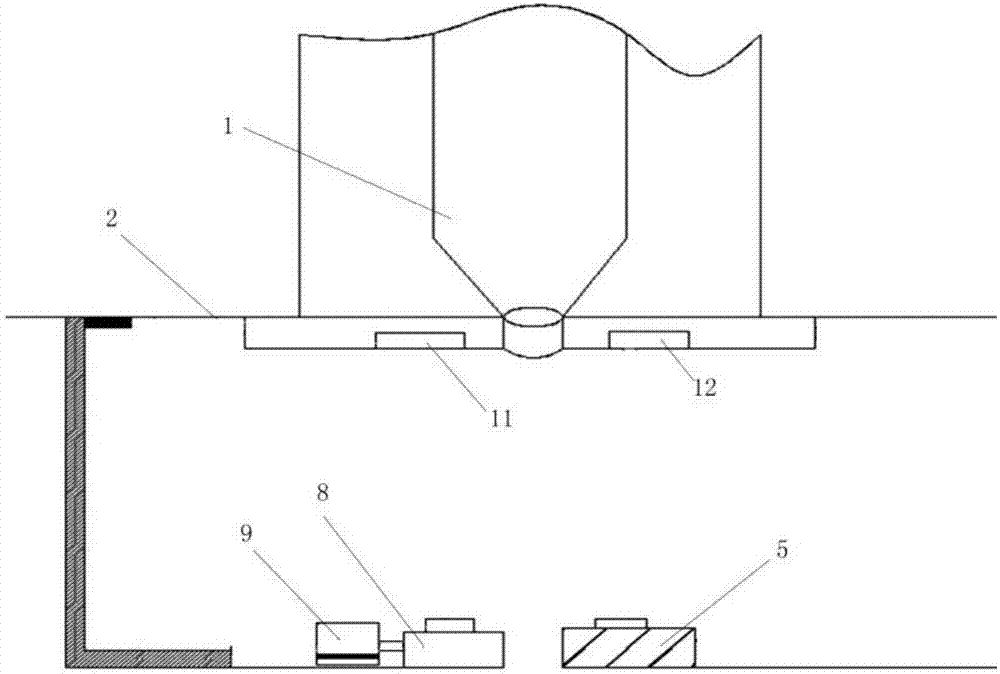

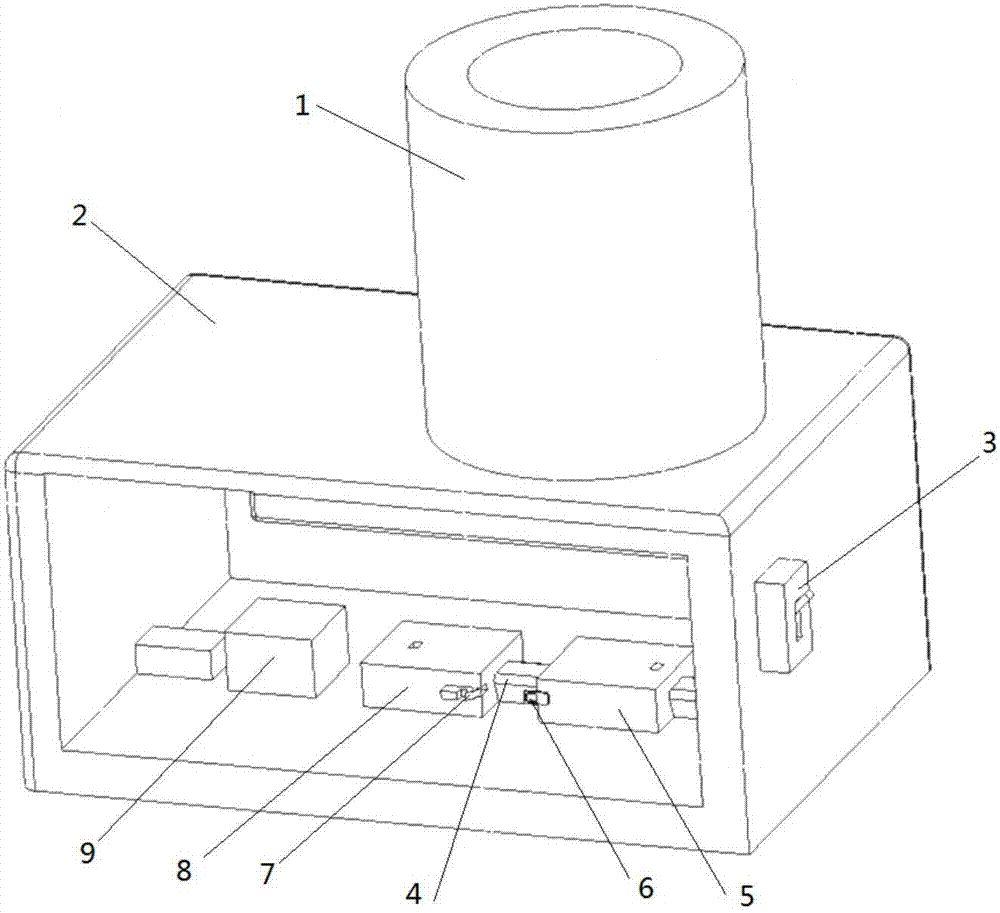

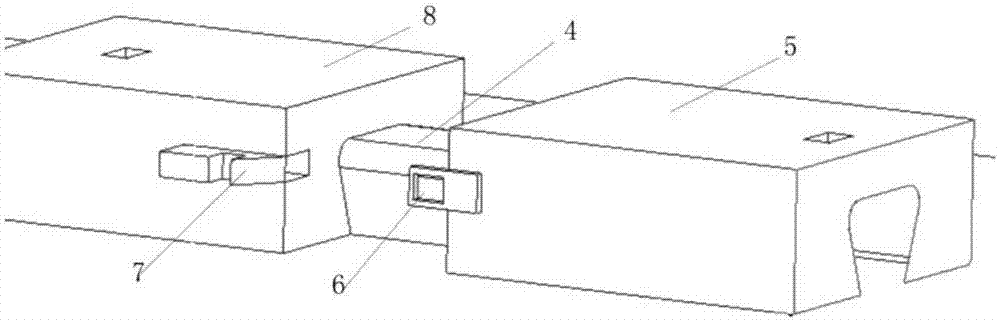

[0030] Such as figure 1 and figure 2 As shown, the present invention includes a housing 2 and a material storage device 1 arranged on the top surface of the housing 2 for placing welding rods. The end of the material storage device 1 is a discharge opening on the top of the housing 2. The housing 2 is provided with a photoelectric sensor facing the discharge port for detecting the discharge of the discharge port. The photoelectric sensor includes a first through-beam photoelectric sensor 11 and a second through-beam photoelectric sensor 12; the housing 2 The bottom surface is also provided with a push-pull electromagnet 9, the extended end of the push-pull electromagnet 9 is connected with the slide block 8 and the push-pull direction of the push-pull electromagnet 9 is parallel to the horizontal guide rail 4, the push-pull electromagnet 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com