Stepless speed governing range hood

A technology for range hoods and stepless speed regulation, which is applied in the field of range hoods. It can solve the problems of heavy adjustment of the rectification plate and the inability to adjust the flow distribution and flow rate of the air inlet simultaneously, so as to improve the suction effect, improve the oil-gas separation effect, reduce the noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

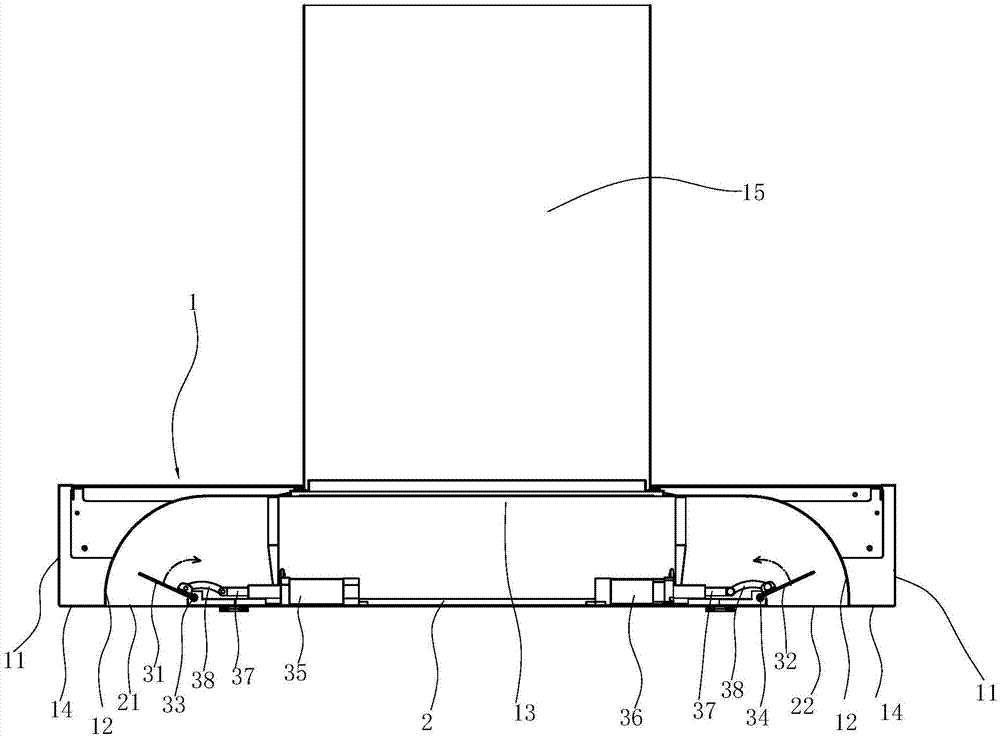

[0026] Such as Figure 1 to Figure 8 As shown, the stepless speed range hood includes:

[0027] The smoke collecting hood 1 is connected under the chassis 15, and is formed by butt joints of the outer cover plate 11 and the inner cover plate 12, wherein the middle part of the inner cover plate 12 is provided to communicate with the volute inlet (not shown in the figure) of the range hood The oil fume suction port 13. The portion between the lowermost end of the inner cover plate 12 and the oil fume suction port 13 is in an arc shape.

[0028] The rectifying plate 2 is arranged in the middle of the inner cover plate 12 corresponding to the oil fume suction port 13, and is connected to the fume collecting hood 1 through the connecting plate 14; the oil fume suction port can be opened when the range hood is working, and the oil fume suction por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com