U-shaped wall base and bottom plate dynamic and static separation bearing type lining structure with water delivering function

A dynamic and static separation, U-shaped technology, used in wellbore lining, tunnel lining, drainage, etc., can solve the problems of cracking and damage of the tunnel bottom structure, and achieve the effect of clear force, saving masonry, and overcoming the difficult control of excavation curvature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

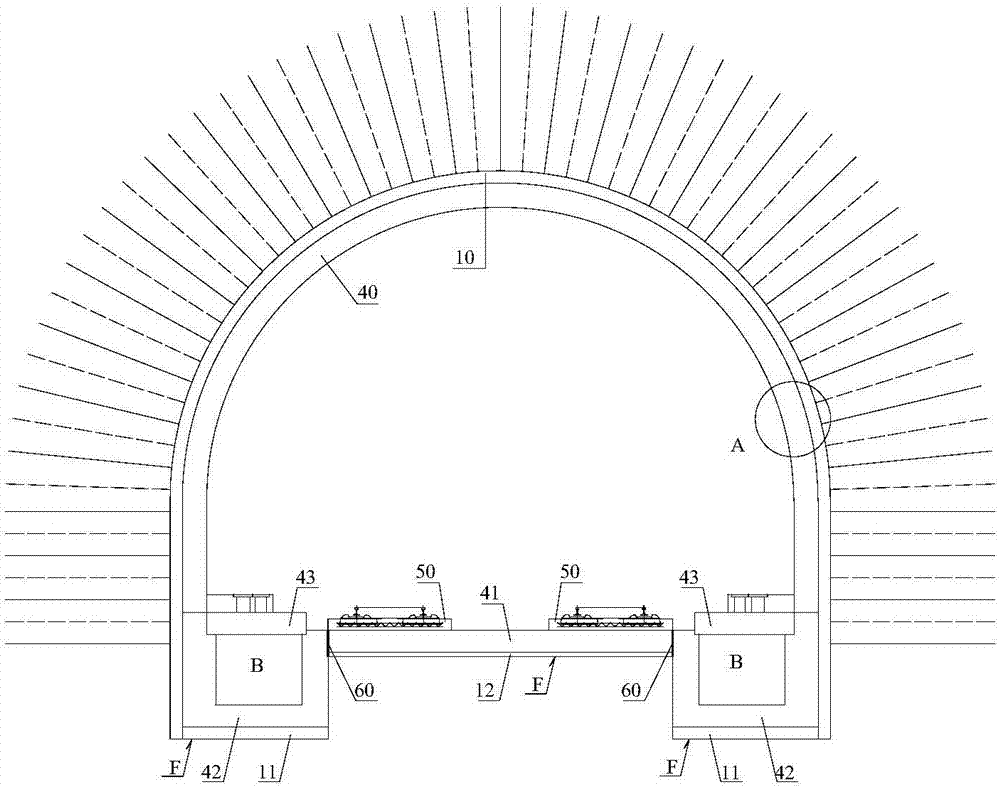

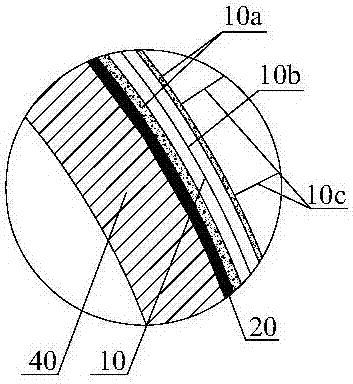

[0027] refer to figure 1 , the U-shaped wall foundation with water delivery function of the present invention and the dynamic and static separation load-bearing lining structure of the base plate include the primary support structure 10 of the arch wall, the secondary lining structure 40 of the arch wall and the waterproof layer 20 in the range of the arch wall. Deep grooves are excavated on both lateral sides of the bottom of the tunnel to form a convex tunnel bottom excavation surface F, and a U-shaped wall foundation structure 42 with a groove-shaped cavity B is arranged in the deep groove, and the outer top of the U-shaped wall foundation structure 42 is connected to the The bottom of the side walls on both sides of the arch wall secondary lining structure 40 is fixed, and the U-shaped wall foundation structure 42 is used as the load-bearing struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com