Treatment method for difficult waterproof curtain pile forming caused by too large filing pile filling coefficient

A technology of water-stop curtain and filling coefficient, which is used in excavation, construction, infrastructure engineering, etc., can solve the problems of excessive filling coefficient, difficult to guarantee, and small net spacing of piles, and achieves wide application, convenient processing and wide application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A method for treating water-stop curtain piles that are difficult to form piles due to excessive filling coefficients of cast-in-place piles, comprising the following steps:

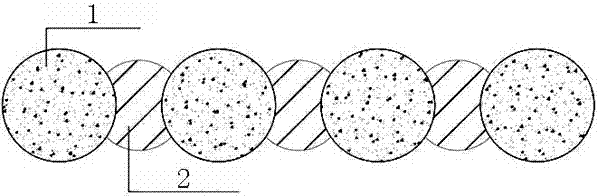

[0022] Such as figure 1 , 2 Shown: Step 1: According to the net spacing of foundation pit surrounding protection piles, geological survey report data, and the actual value of the concrete filling coefficient of on-site construction, it is normal for the concrete filling coefficient to be less than 1.2, and preliminarily judge the "neck expansion" of concrete pouring pile 1;

[0023] Step 2: After the cast-in-place pile reaches more than 70% of the design strength, carry out the construction of the rotary spraying water-stop curtain pile at the midpoint of the line connecting the centers of the adjacent cast-in-place piles according to the design drawings;

[0024] Step 3: For piles with serious "neck expansion" of concrete pouring piles, it may be difficult or impossible to drill with rotary grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com