Pellet feed crushing machine for breeding

A pellet feed and mill technology, applied in feed, application, solid separation, etc., can solve the problems of reduced feeding efficiency, low crushing efficiency, time-consuming and labor-intensive, etc., and achieve the effect of preventing the feeding speed from being too fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

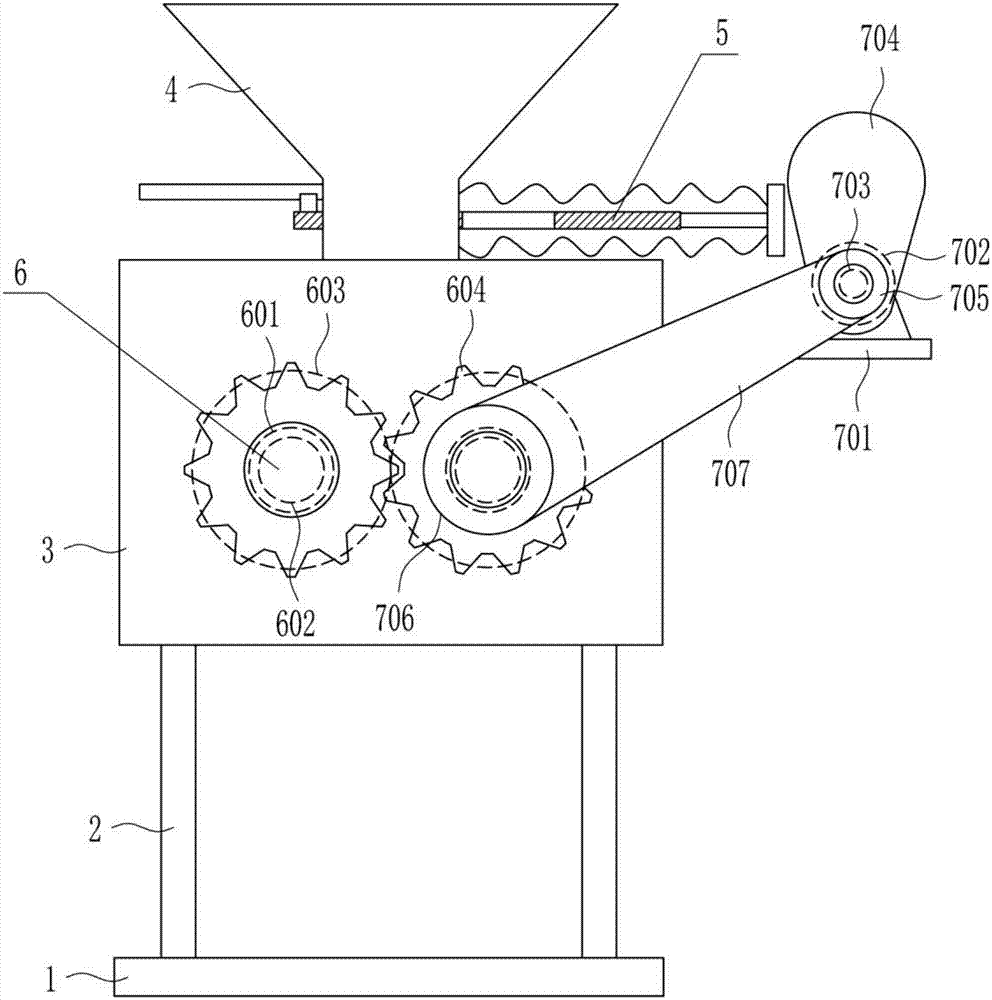

Embodiment 1

[0031] A pellet feed mill for aquaculture, such as Figure 1-5 As shown, it includes a base 1, a support rod 2, a box body 3, a first lower hopper 4, a lowering device 5, a crushing device 6, a driving device 7 and a sieve plate 9, and the left and right sides of the top of the base 1 are vertical A support rod 2 is connected, and a box body 3 is connected between the top ends of the two support rods 2. A first lower hopper 4 is installed on the top of the box body 3, and a feeding device 5 is arranged in the first lower hopper 4. The box body 3 There is a crushing device 6 inside, a driving device 7 is arranged on the upper part of the right side of the box body 3, a first chute 8 is horizontally opened at the bottom of the box body 3, and a sieve plate 9 is arranged in the first chute 8. A discharge port 10 is opened at the bottom of the body 3 , and the discharge port 10 communicates with the first chute 8 .

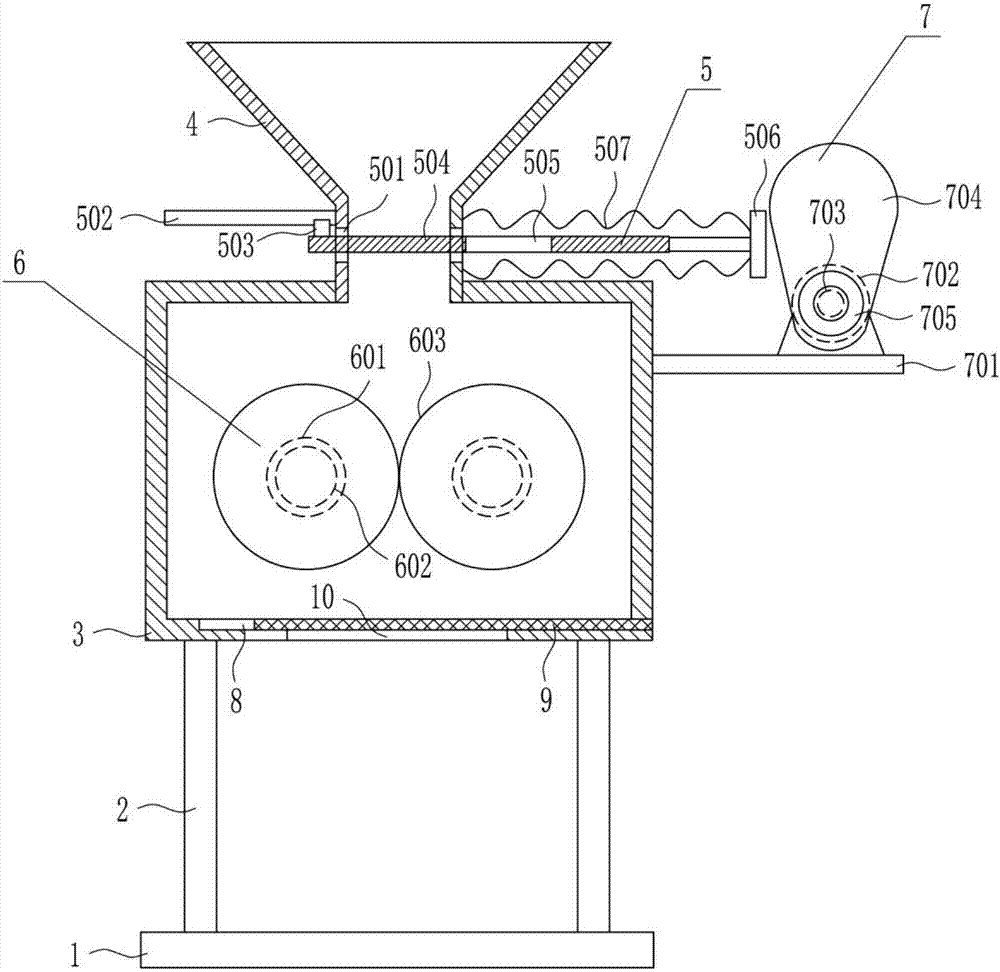

Embodiment 2

[0033] A pellet feed mill for aquaculture, such as Figure 1-5 As shown, it includes a base 1, a support rod 2, a box body 3, a first lower hopper 4, a lowering device 5, a crushing device 6, a driving device 7 and a sieve plate 9, and the left and right sides of the top of the base 1 are vertical A support rod 2 is connected, and a box body 3 is connected between the top ends of the two support rods 2. A first lower hopper 4 is installed on the top of the box body 3, and a feeding device 5 is arranged in the first lower hopper 4. The box body 3 There is a crushing device 6 inside, a driving device 7 is arranged on the upper part of the right side of the box body 3, a first chute 8 is horizontally opened at the bottom of the box body 3, and a sieve plate 9 is arranged in the first chute 8. A discharge port 10 is opened at the bottom of the body 3 , and the discharge port 10 communicates with the first chute 8 .

[0034] The unloading device 5 includes a slide rail 502, a firs...

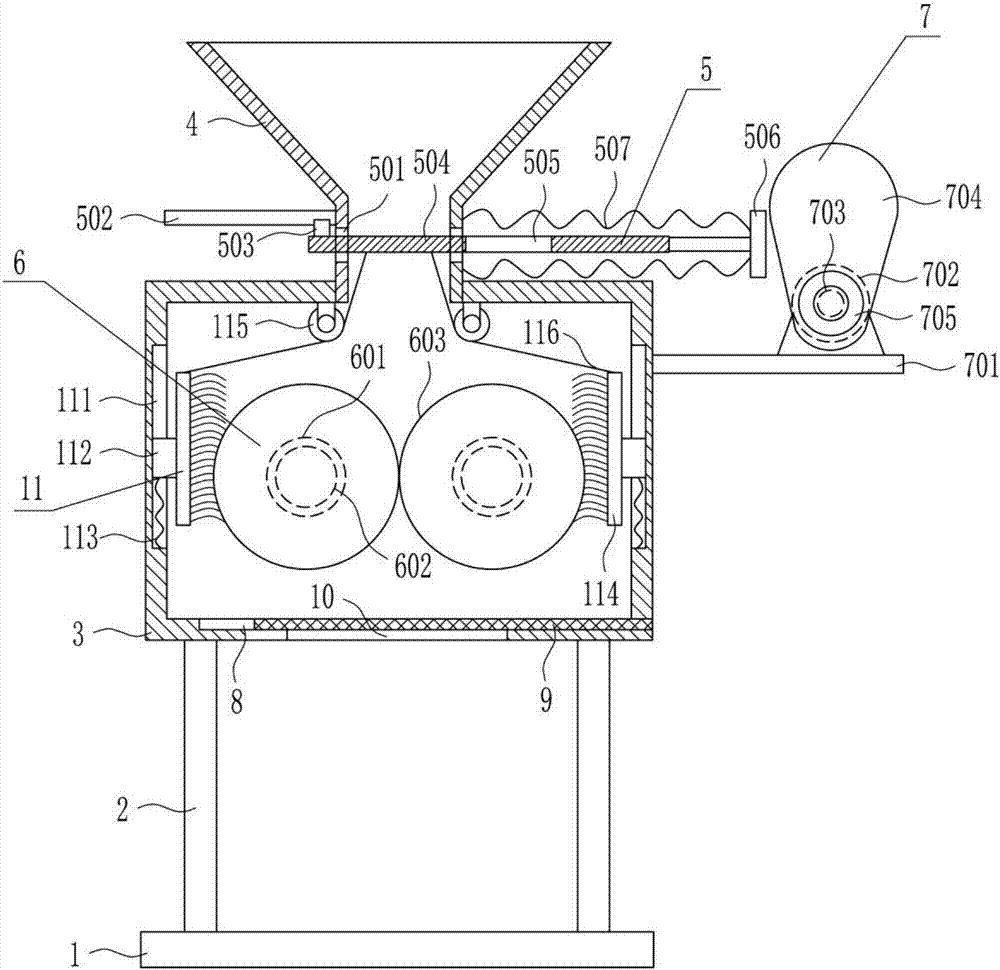

Embodiment 3

[0036] A pellet feed mill for aquaculture, such as Figure 1-5 As shown, it includes a base 1, a support rod 2, a box body 3, a first lower hopper 4, a lowering device 5, a crushing device 6, a driving device 7 and a sieve plate 9, and the left and right sides of the top of the base 1 are vertical A support rod 2 is connected, and a box body 3 is connected between the top ends of the two support rods 2. A first lower hopper 4 is installed on the top of the box body 3, and a feeding device 5 is arranged in the first lower hopper 4. The box body 3 There is a crushing device 6 inside, a driving device 7 is arranged on the upper part of the right side of the box body 3, a first chute 8 is horizontally opened at the bottom of the box body 3, and a sieve plate 9 is arranged in the first chute 8. A discharge port 10 is opened at the bottom of the body 3 , and the discharge port 10 communicates with the first chute 8 .

[0037] The unloading device 5 includes a slide rail 502, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com