Full-automatic socket switch pedestal assembling equipment

A technology of socket switch and assembly equipment, which is applied in the direction of assembly/disassembly of electric switches, contacts, and electrical components, etc. It can solve the problems of poor mechanical and electrical performance, heavy labor, and low production efficiency, and achieve the assembly effect Good, high degree of automation, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

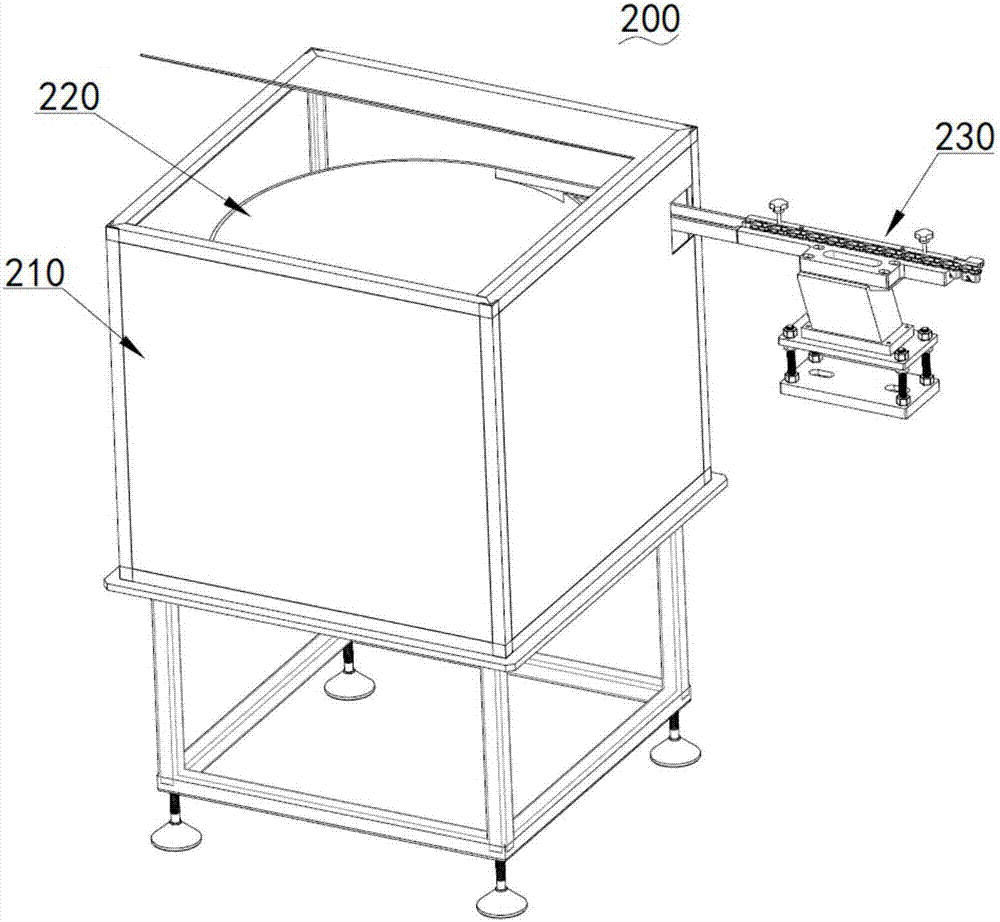

[0037] like figure 1 Shown is a perspective view of the present invention.

[0038] A fully automatic socket switch base assembly device 10, including a frame 100, which is used to support and fix the placement of the frame 100, and is provided on the frame 100 with a base feeding device 200, a first pole piece feeding device 300, and a second pole piece feeding device 300. Sheet feeding device 400, resistance feeding device 500, bending device 600, and assembly line 700. Multiple feeding devices are used to load and assemble different accessories, which has a high degree of automation and saves manpower. After 600 pairs of bending devices are assembled The pole piece is bent, which is convenient for the later manufacturing process, and the manufacturing efficiency is high. One end of the assembly line 700 and the first pole piece feeding device 300 pass through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com