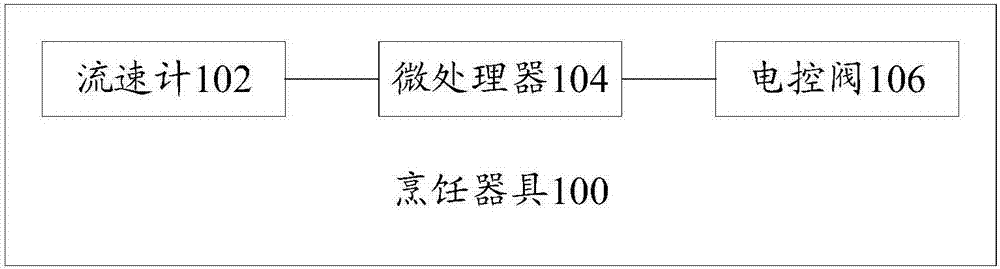

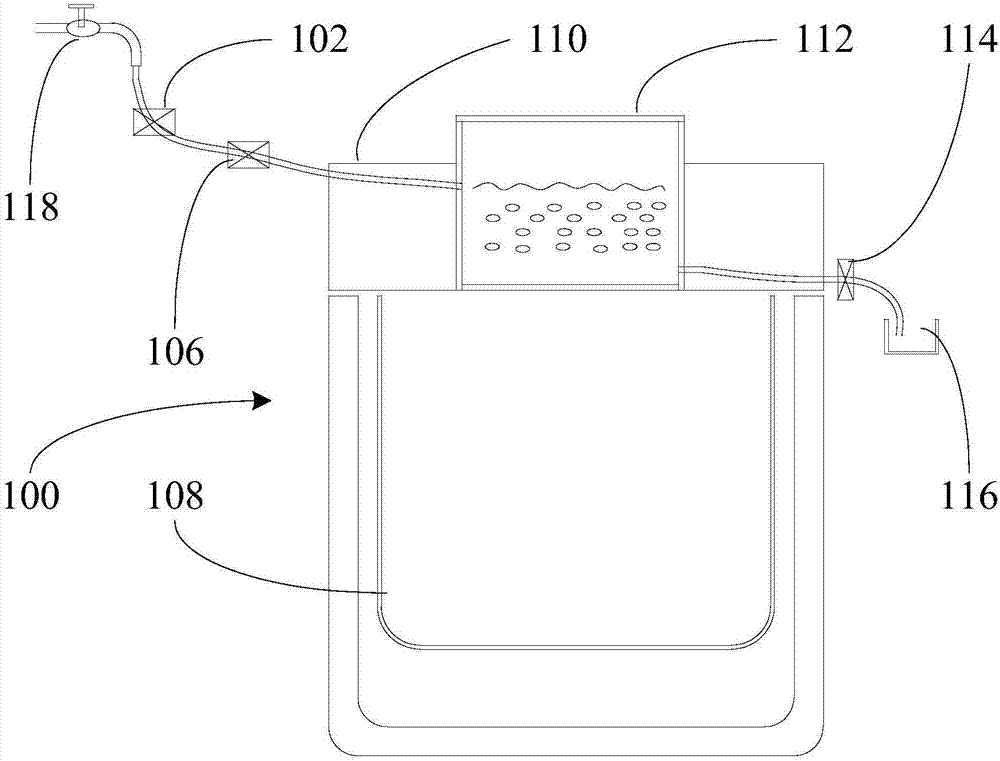

Cooking appliance, flow rate control method and flow rate control device

A technology of flow rate and flow meter, which is applied in the direction of flow control, flow control using electric devices, non-electric variable control, etc. It can solve the problems of control process deviation and poor flexibility of cooking process, and achieve high flow rate, rapid action and sensitive response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The opening and closing degree is 100% (fully open), and the flowable area is as image 3 as shown in the 302 area;

Embodiment 2

[0073] The opening and closing degree is 80%, and the circulation area such as Figure 4 As shown in the 402 area, the non-tradable area is as follows Figure 4 as shown in the 404 area;

Embodiment 3

[0075] The opening and closing degree is 50%, and the circulation area such as Figure 5 As shown in the 502 area, non-negotiable areas such as Figure 5 as shown in the 504 area of the

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com