A uniform ore addition equipment for rare earth production

A uniform and ore technology, applied in the field of uniform ore addition equipment for rare earth production, can solve the problems of non-uniform ore addition, manual ore addition, unfavorable use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

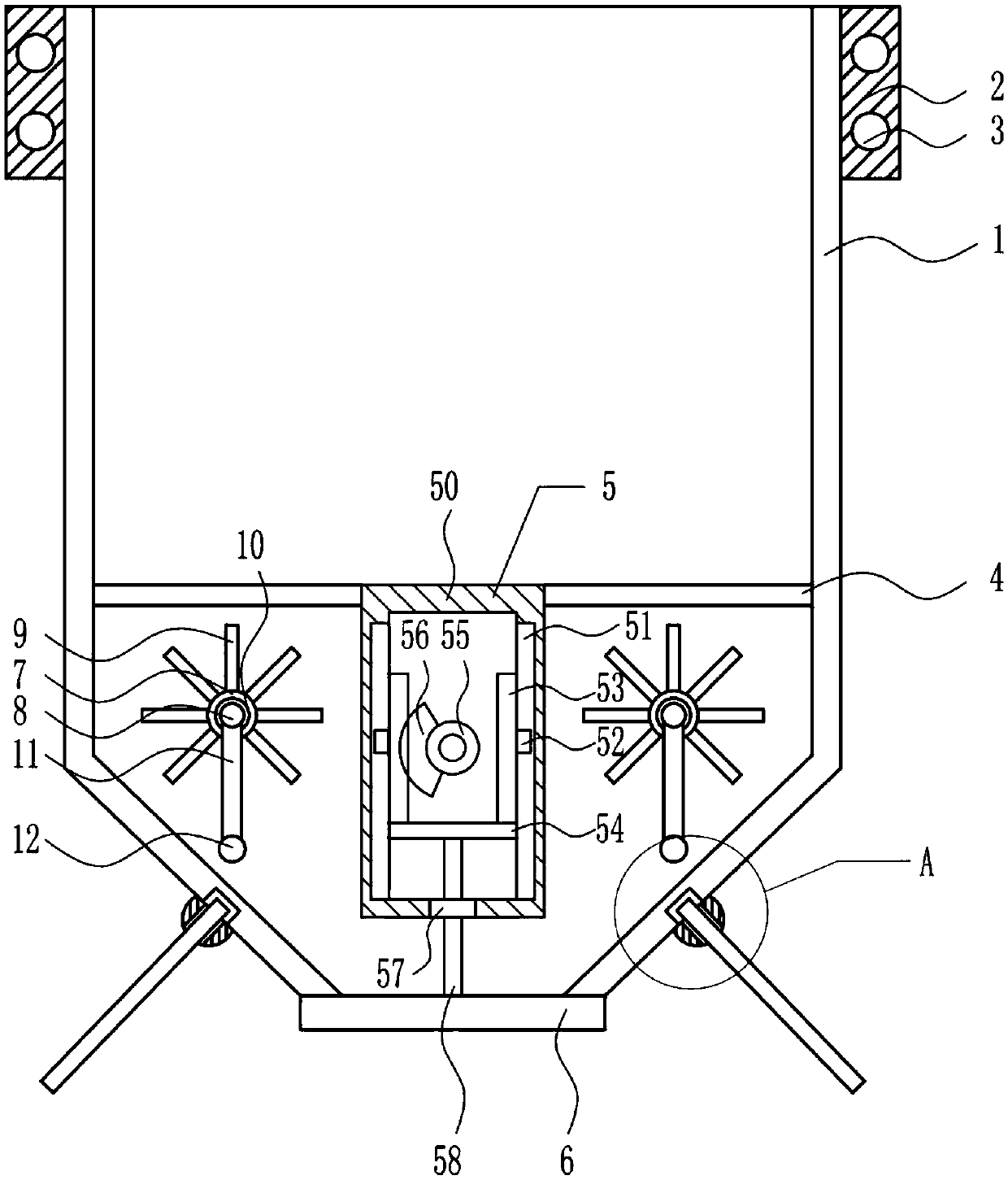

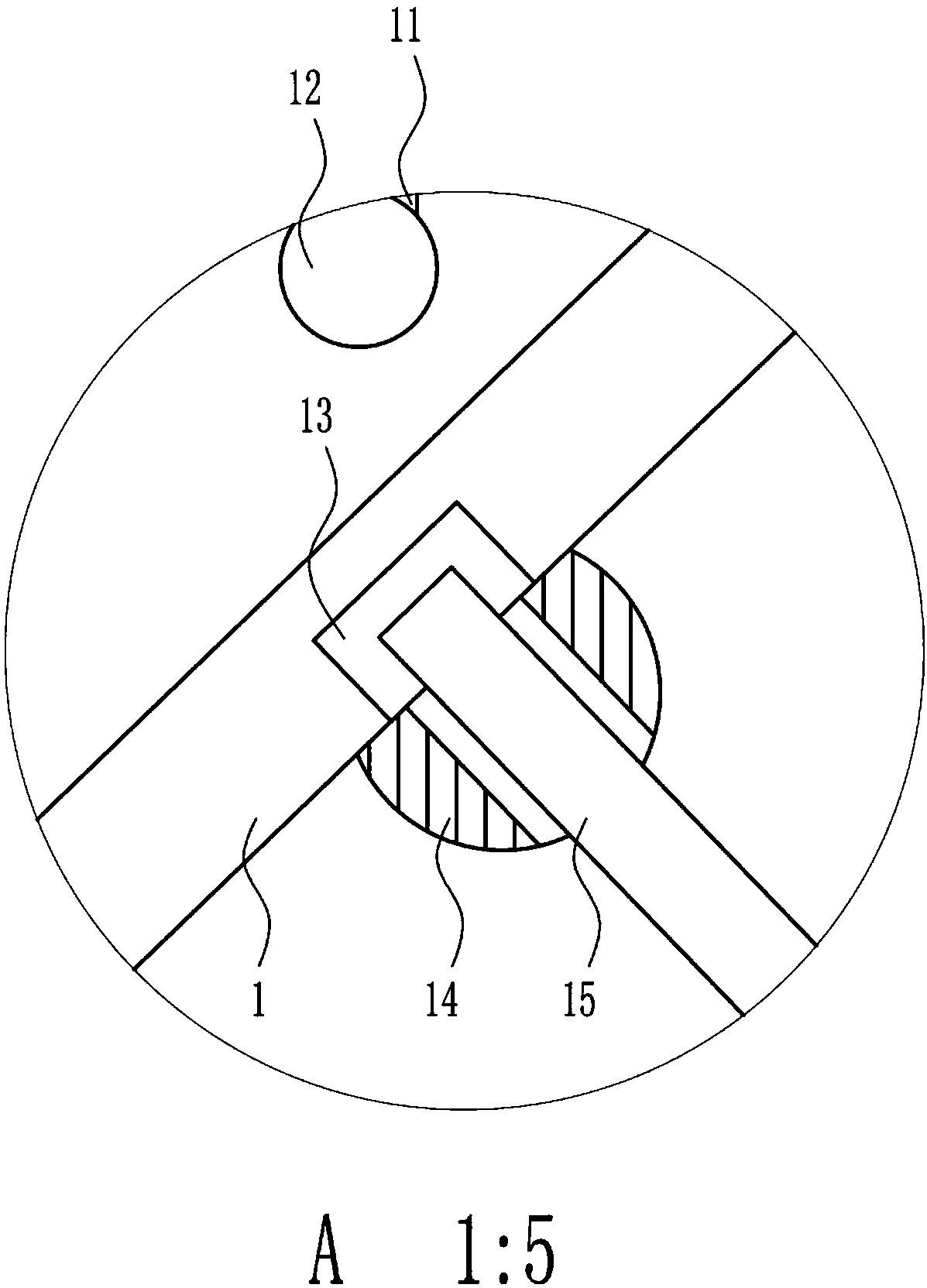

[0024] A kind of equipment for evenly adding ore for rare earth production, such as Figure 1-2 As shown, it includes a material storage box 1, a mounting plate 2, a pole 4, a lifting mechanism 5 and a baffle plate 6. The upper part of the outer side of the left and right walls of the material storage box 1 is symmetrically provided with a mounting plate 2, and the mounting plate 2 is symmetrically opened up and down. Hole 3, the inner lower part of the left and right walls of the storage box 1 are provided with support rods 4, the left and right sides of the support rods 4 are provided with a lifting mechanism 5, the lower end of the lifting mechanism 5 is provided with a baffle plate 6, and the baffle plate 6 is located in the storage box 1 bottom.

Embodiment 2

[0026] A kind of equipment for evenly adding ore for rare earth production, such as Figure 1-2 As shown, it includes a material storage box 1, a mounting plate 2, a pole 4, a lifting mechanism 5 and a baffle plate 6. The upper part of the outer side of the left and right walls of the material storage box 1 is symmetrically provided with a mounting plate 2, and the mounting plate 2 is symmetrically opened up and down. Hole 3, the inner lower part of the left and right walls of the storage box 1 are provided with support rods 4, the left and right sides of the support rods 4 are provided with a lifting mechanism 5, the lower end of the lifting mechanism 5 is provided with a baffle plate 6, and the baffle plate 6 is located in the storage box 1 bottom.

[0027] Lifting mechanism 5 also includes casing 50, slide rail 51, slide block 52, tooth bar 53, connecting rod 54, motor 55, gear 56, guide sleeve 57, moving bar 58 and baffle plate 6, left and right sides pole 4 There is a bo...

Embodiment 3

[0029] A kind of equipment for evenly adding ore for rare earth production, such as Figure 1-2 As shown, it includes a material storage box 1, a mounting plate 2, a pole 4, a lifting mechanism 5 and a baffle plate 6. The upper part of the outer side of the left and right walls of the material storage box 1 is symmetrically provided with a mounting plate 2, and the mounting plate 2 is symmetrically opened up and down. Hole 3, the inner lower part of the left and right walls of the storage box 1 are provided with support rods 4, the left and right sides of the support rods 4 are provided with a lifting mechanism 5, the lower end of the lifting mechanism 5 is provided with a baffle plate 6, and the baffle plate 6 is located in the storage box 1 bottom.

[0030] Lifting mechanism 5 also includes casing 50, slide rail 51, slide block 52, tooth bar 53, connecting rod 54, motor 55, gear 56, guide sleeve 57, moving bar 58 and baffle plate 6, left and right sides pole 4 There is a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com