Air filter air inflow pipe and iron support riveting tool

A technology for air filter intake pipes and iron brackets, which is applied to household components, household appliances, and other household appliances. It can solve the problems that hinder the mass production of products, be easily complained by customers, and the holes are easy to deviate, so as to improve product quality. , Improve production efficiency, reduce the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

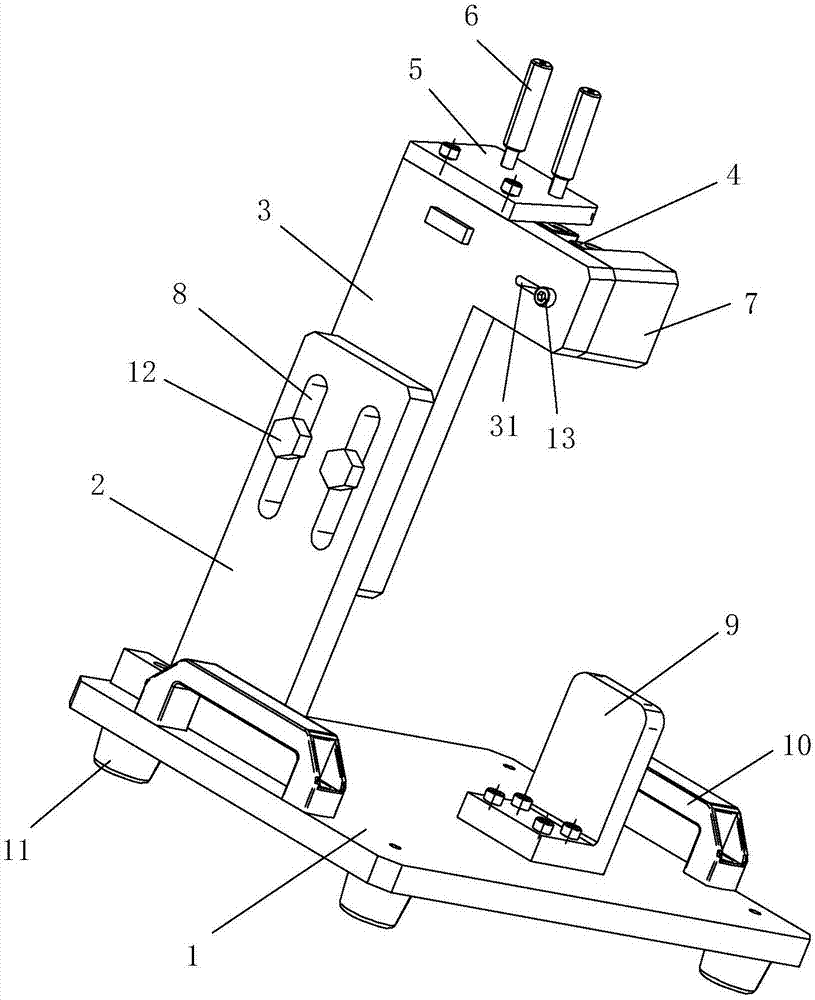

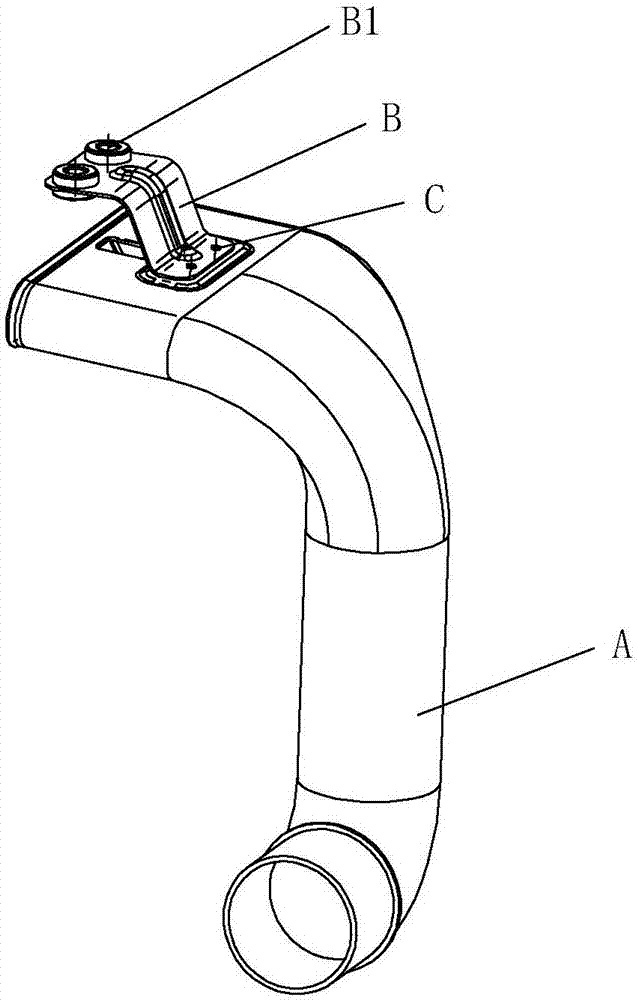

[0019] Example 1: A riveting tool for air filter intake pipe and iron bracket, such as Figure 1-Figure 2 As shown, it includes a bottom plate 1, a supporting plate 2, an adjusting plate 3, an intake pipe positioning plate 4 for supporting and positioning the oval end of the intake pipe, a vertical plate 9 for limiting the round end of the intake pipe, and two iron brackets for positioning The positioning pin 6, the supporting plate and the vertical plate are fixed on the bottom plate, the supporting plate and the adjusting plate are both opened with a longitudinal elongated through hole 8, the adjusting plate passes through the longitudinal elongated through hole The fastening bolts I12 of the I12 are installed on the support plate, the top of the adjusting plate is equipped with an iron bracket positioning plate 5, the iron bracket positioning plate has two positioning pin holes, the intake pipe positioning plate is connected to the adjusting plate and is located on the iron br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com