Charging tray mounting structure of silk feeder

An installation structure and a material tray technology are applied in the field of device structures in the production process of pipe piles, which can solve the problems of hidden dangers, affect the production progress, and easily messed up threads, so as to avoid potential safety hazards, ensure the production progress, and not easily mess up the heads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

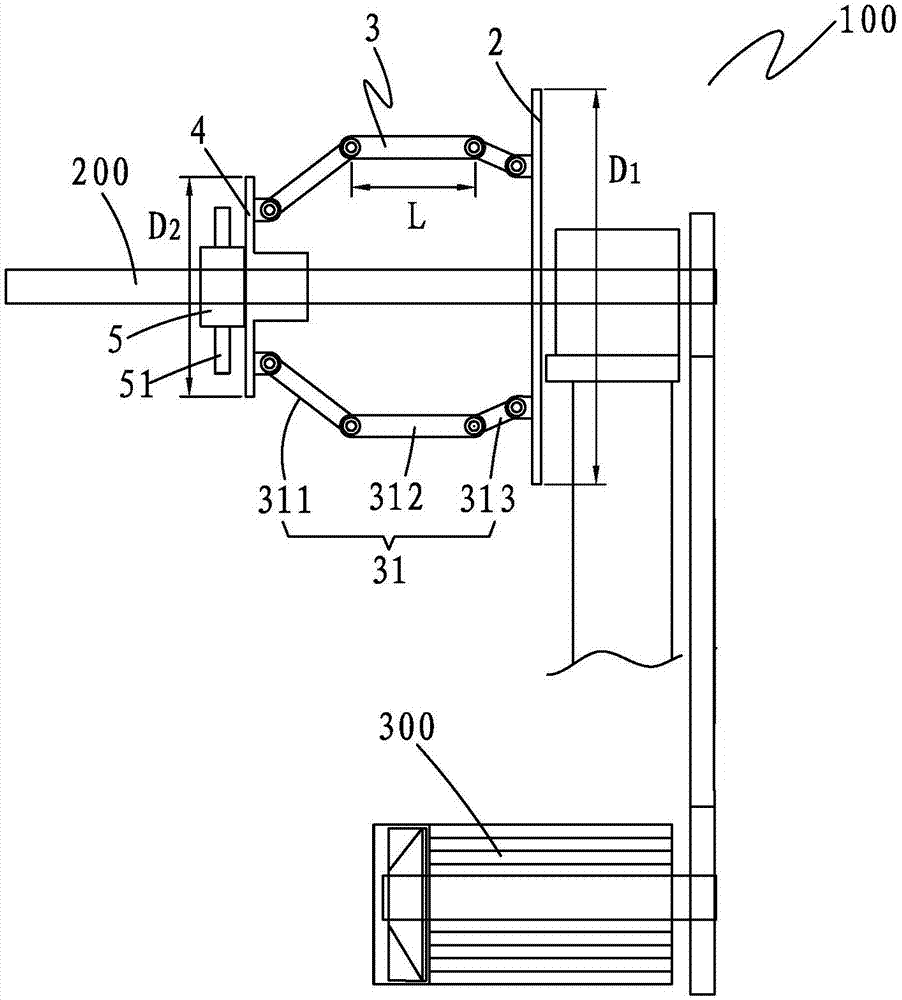

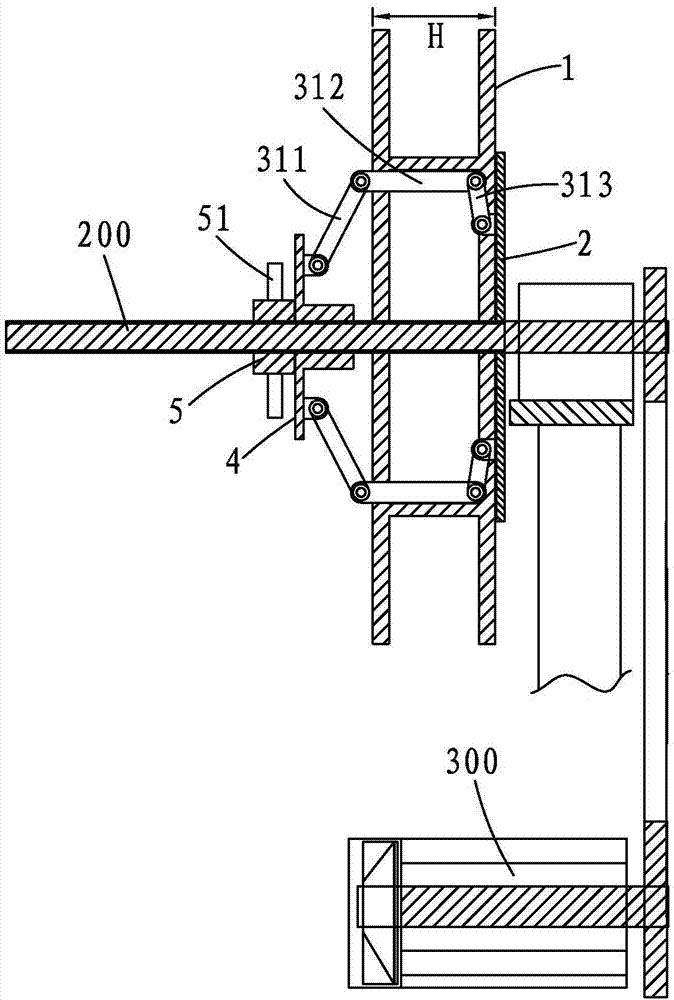

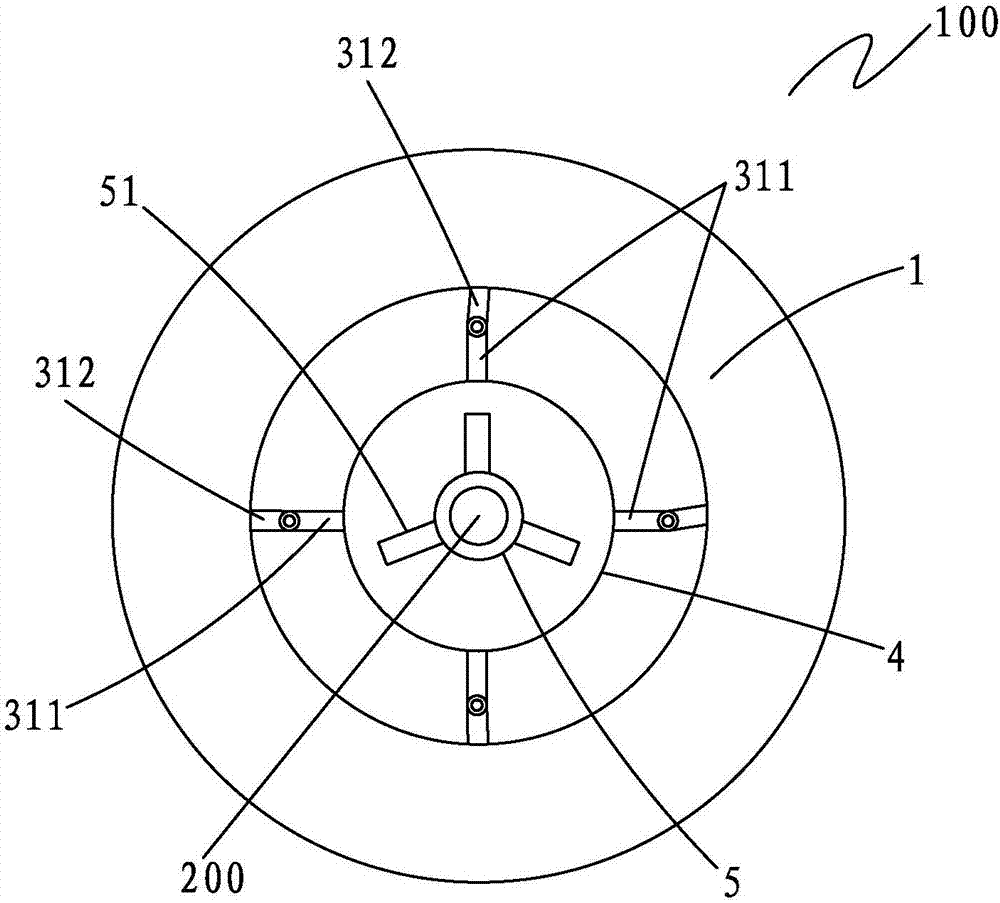

[0017] Please refer to Figure 1 to Figure 3 , a material tray installation structure 100 of a wire feeding machine according to the present invention, comprising a material tray 1, a fixed disc 2 arranged in sequence, a locking frame 3 passing through the material tray 1, a movable disc 4, a A nut 5 matched with the main shaft 200 of the wire loading machine.

[0018] The fixed disc 2 is fixed on the end section of the main shaft 200 of the wire feeding machine, the diameter of the fixed disc 2 is D1, the inner diameter of the material tray 1 is d, D1>d, and the movable disc 4 is slipped on the upper wire On the main shaft 200 of the wire feeding machine, the diameter of the movable disc 4 is D2, D2<d, and the centerlines of the fixed disc 2 and the movable disc 4 overlap with the centerline of the main shaft 200 of the wire feeding machine, and the nut 5 is rotated on the main shaft 200 of the wire loading machine and offsets with the movable disk 4.

[0019] The locking f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com