Fertilizer production device

An equipment and fertilizer technology, applied in the field of fertilizer production equipment, can solve the problems of inaccurate control of the disc inclination, low granulation efficiency, and unstable operation, and achieve the effects of simple structure, convenient movement, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

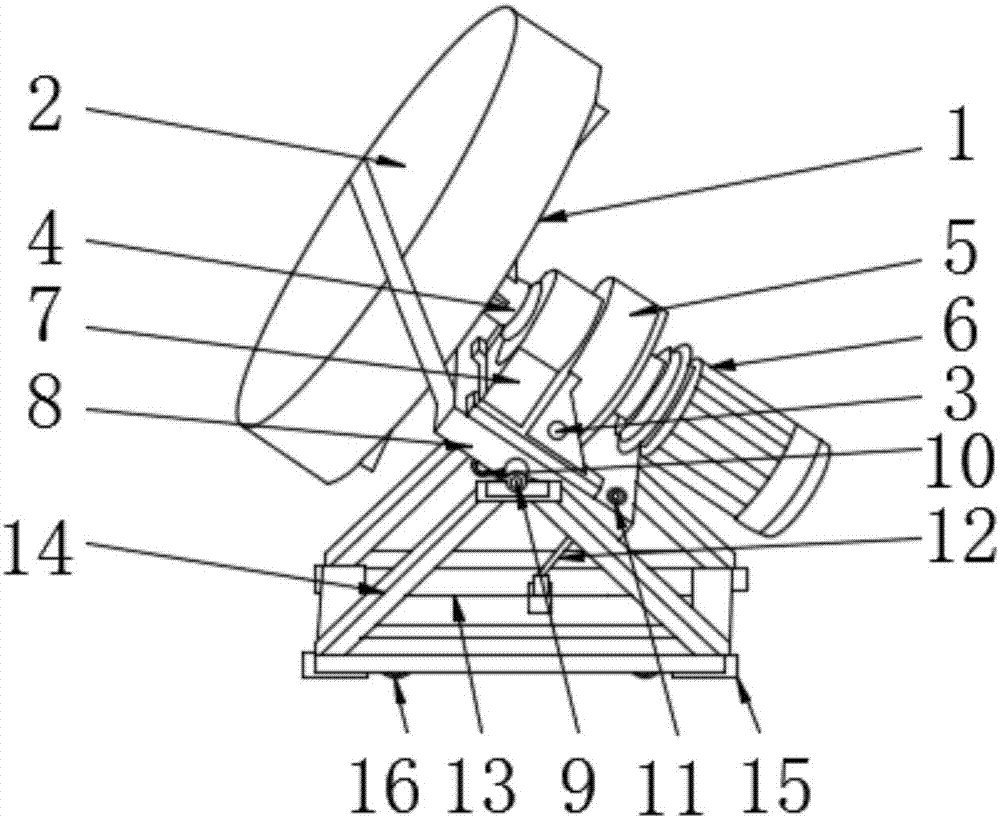

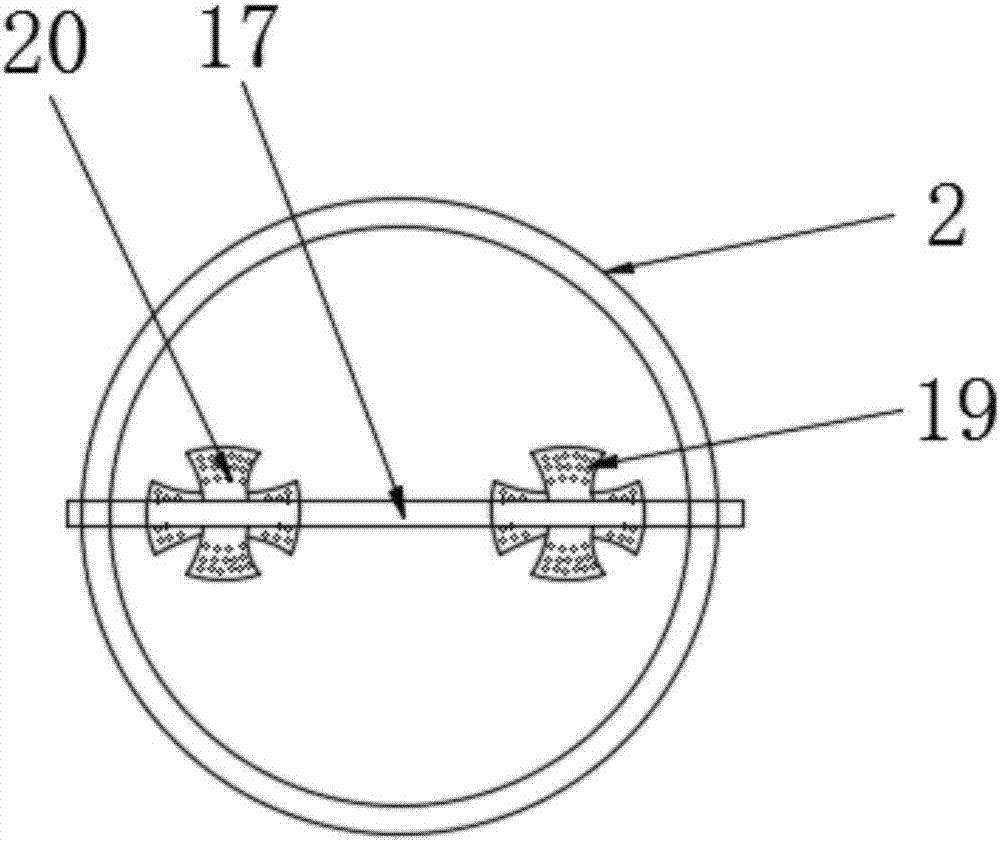

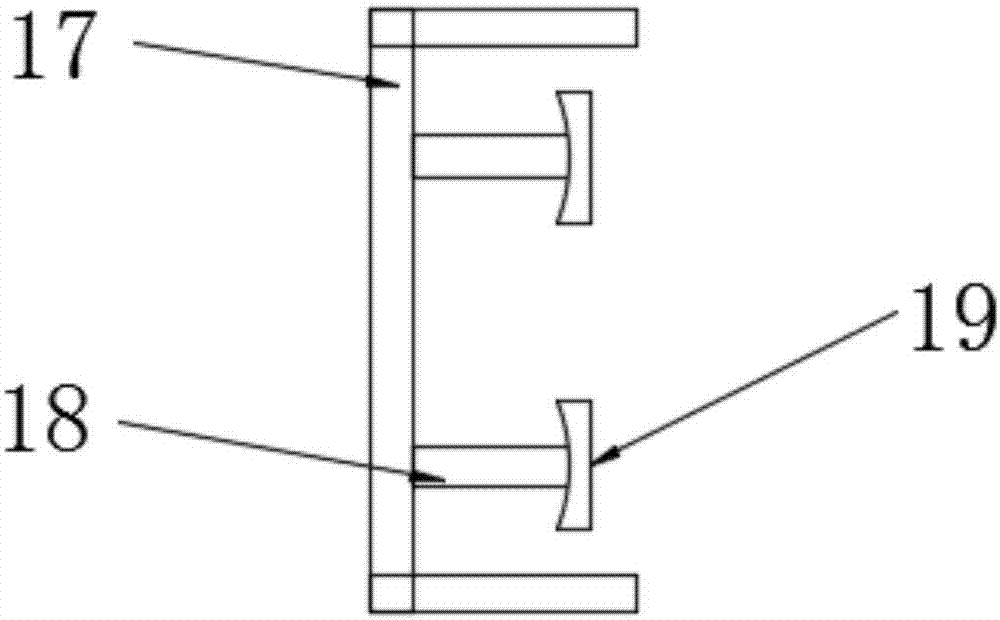

[0018] Example: such as Figure 1-3 As shown, the present invention provides a technical solution for fertilizer production equipment, a fertilizer production equipment, including a granulator body 1, a silo 2, a control switch 3, a rotating shaft 4, a reducer 5, a motor 6, a protection seat 7, and a support plate 8 , adjusting seat 9, weight 10, hand wheel 11, adjusting screw 12, base 13, main frame 14, foundation support block 15, universal wheel 16, beam 17, column 18, scraper 19 and slot 20, One side of the granulator body 1 is provided with a silo 2, the outer side of the silo 2 is provided with a beam 17, one side of the beam 17 is provided with a column 18, one side of the column 18 is installed with a scraper 19, and the surface of the scraper 19 is provided with There is a slotted hole 20, the rear side of the feed bin 2 is provided with a rotating shaft 4, one side of the rotating shaft 4 is provided with a speed reducer 5, and one side of the speed reducer 5 is equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com