Production method of 3D printing fibula reconstruction jaw surgical tool combining bone excision with titanium-plate positioning

A manufacturing method and technology of surgical tools, applied in surgery, bone drill guidance, additive processing, etc., can solve problems such as difficult preparation, manual operation errors, and high subjectivity, and achieve high efficiency in the placement process, improved stability, and surgical high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

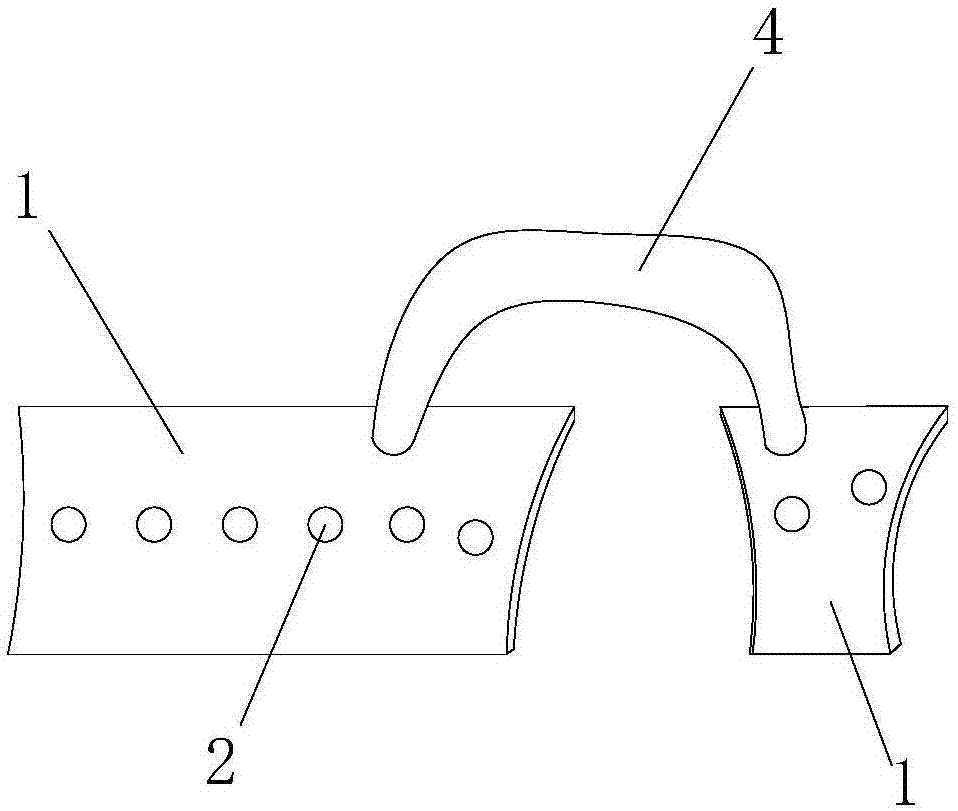

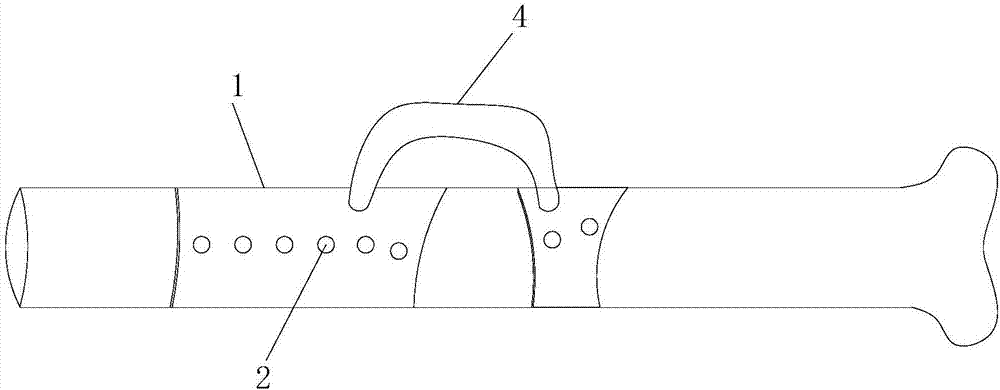

[0039] A method for manufacturing a 3D printed fibular reconstruction jaw surgery tool combined with bone resection and titanium plate positioning, comprising the following steps:

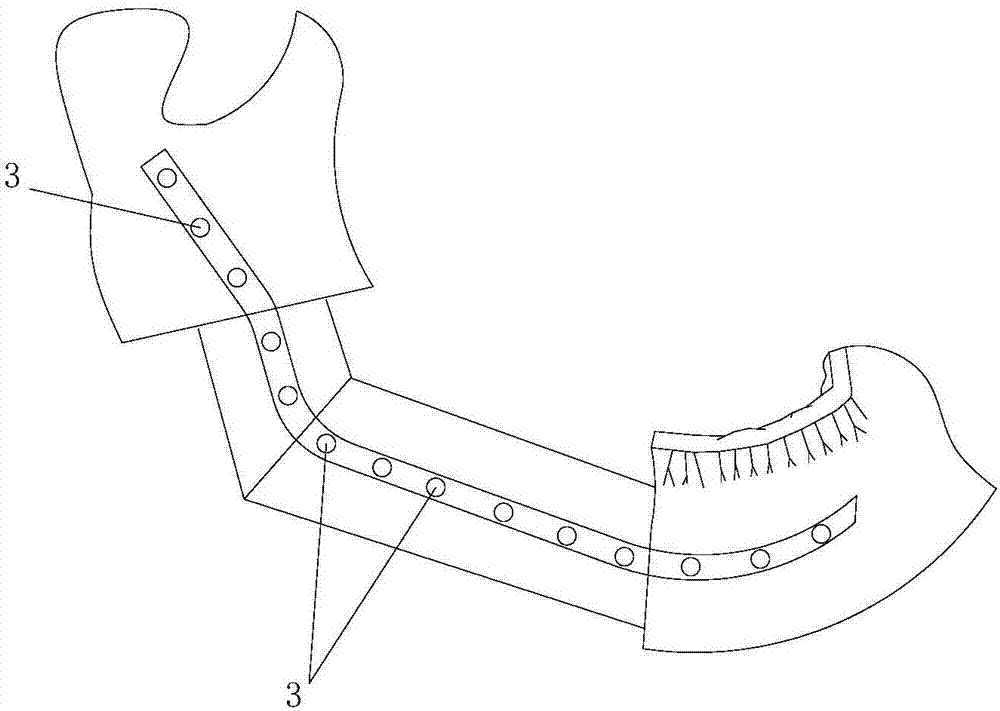

[0040] Step 1. Personalized sampling and surgical simulation: Use CBCT or spiral CT to scan the patient's upper and lower jaw and fibula donor sites, import the imaging data into the surgical design simulation software in Dicom standard format, use threshold division, region growth and multi-layer lasso and other functions to segment images and reconstruct the 3D models of the upper and lower jaws and fibula, such as image 3 shown.

[0041] Step 2. Determine the jaw osteotomy plane according to the extent of the lesion, draw multiple spatial points in the defect area to form a spatial fold line, and simulate the fibula transplantation to the jaw defect area to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com