Device for improving stripping efficiency of cable for engineering

A cable and wire stripping technology, applied in the mechanical field, can solve the problems of low efficiency, unsuitable cable stripping operation, troublesome operation, etc., and achieve the effect of expanding the scope of application, improving the stripping efficiency, and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

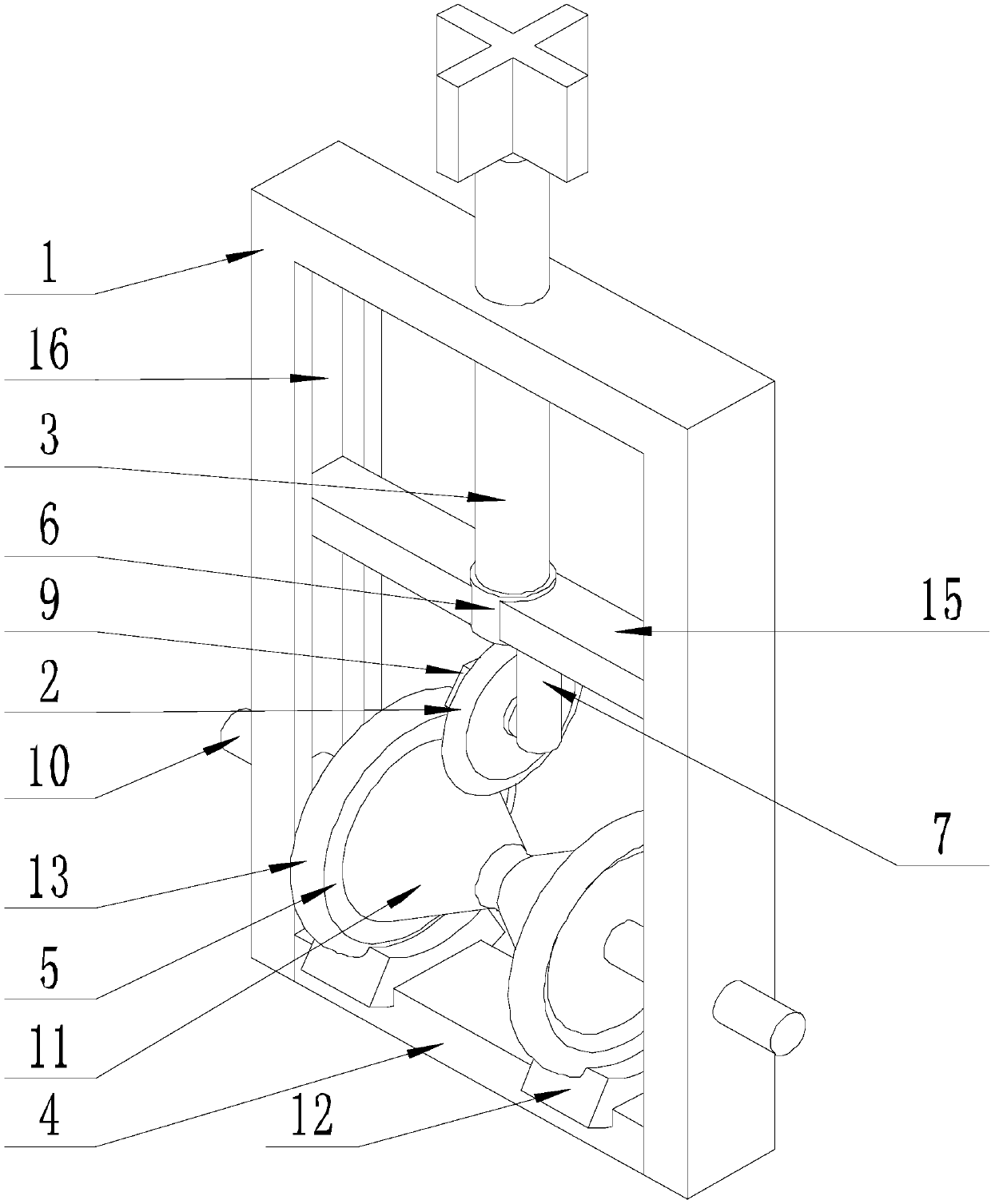

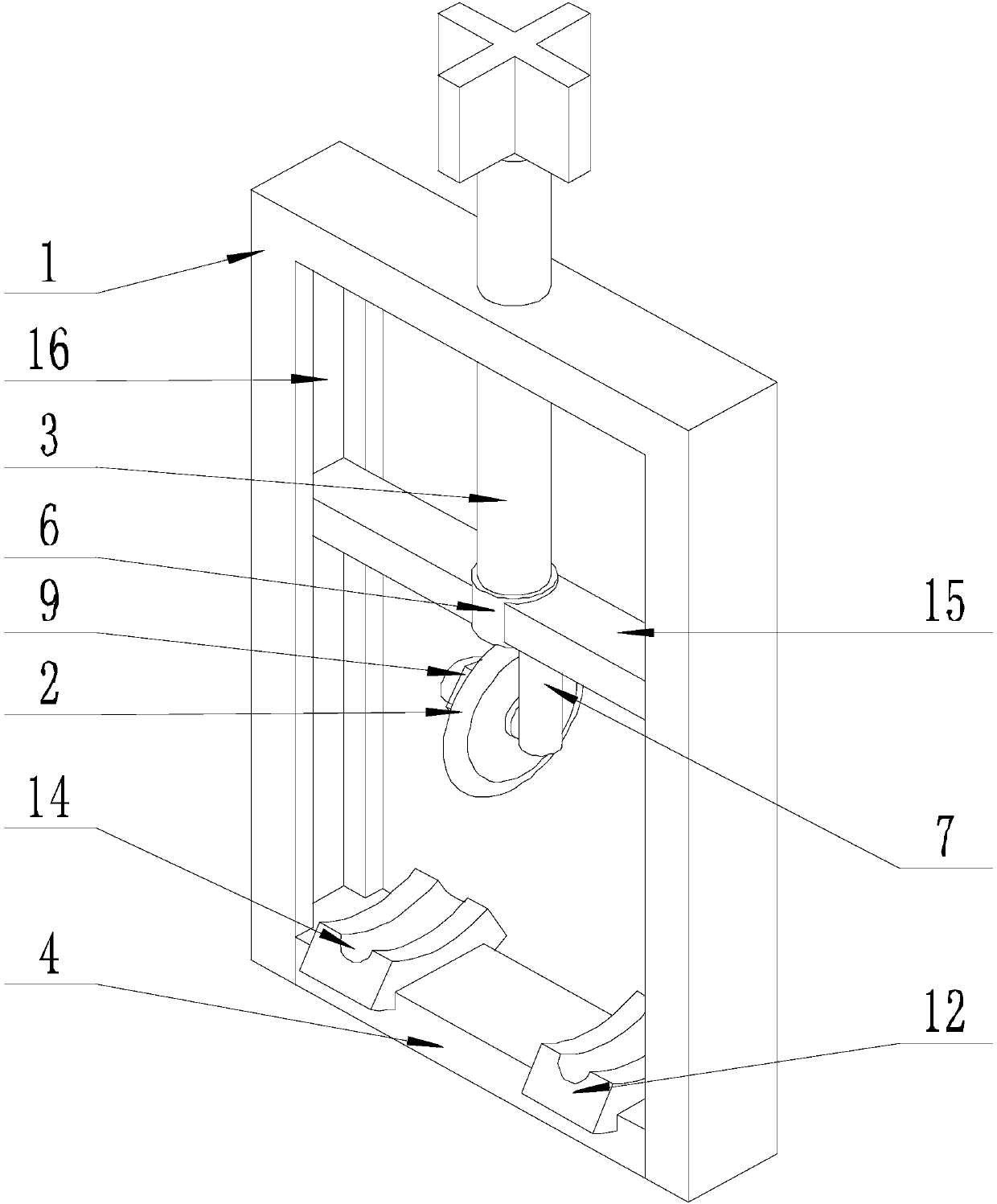

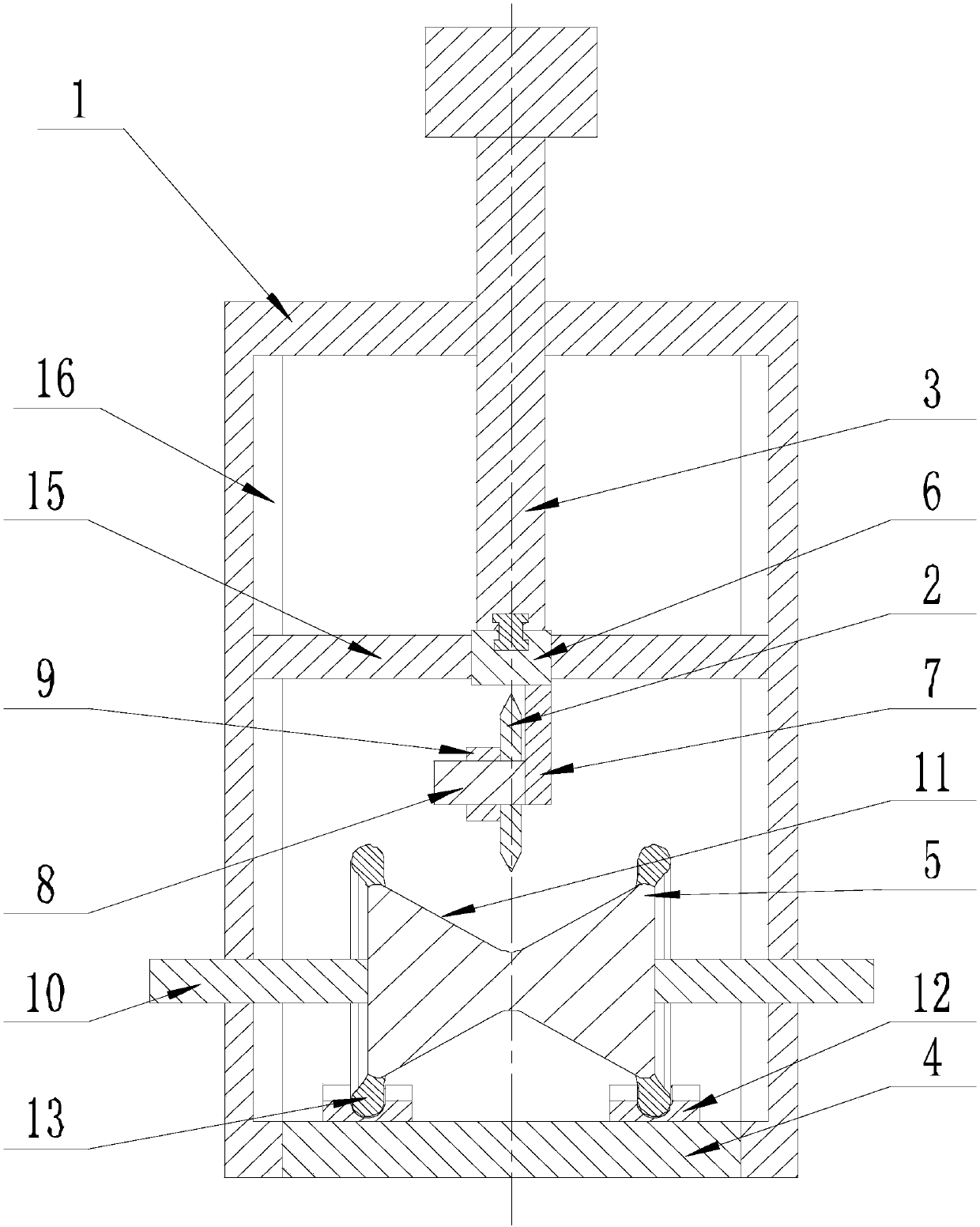

[0045] Such as Figure 1-Figure 4 As shown, the device for improving the efficiency of engineering cable stripping in the present invention includes a gantry 1, a screw 3 and a rotating block 6 connected in sequence, the gantry 1 having a door-shaped surface perpendicular to the ground, and its opening facing downwards , a cutter 2 is arranged inside the gantry 1, one end of the screw rod 3 is threadedly connected with the top of the gantry 1, the other end of the screw rod 3 is rotatably connected with one end of the rotating block 6, and the other end of the rotating block 6 One end is connected with the cutter 2, and the screw rod 3 is rotated to make the cutter 2 move along the centerline of the portal frame 1;

[0046]Described cutting knife 2 is a disk, and its axis is perpendicular to the center line of gantry 1 and is parallel to the portal surface of gantry 1, and the blade of cutting knife 2 is positioned at the side wall of cutting knife 2, and along cutting The pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com