Cable insulation cover layer stripping mechanism

A technology of cable insulation and covering layer, which is applied in the direction of cable installation, disassembly/armored cable equipment, cable installation device, etc. It can solve the problems of low efficiency, inapplicable cable stripping operation, troublesome operation, etc., and achieve simplified operation steps, reduce maintenance costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

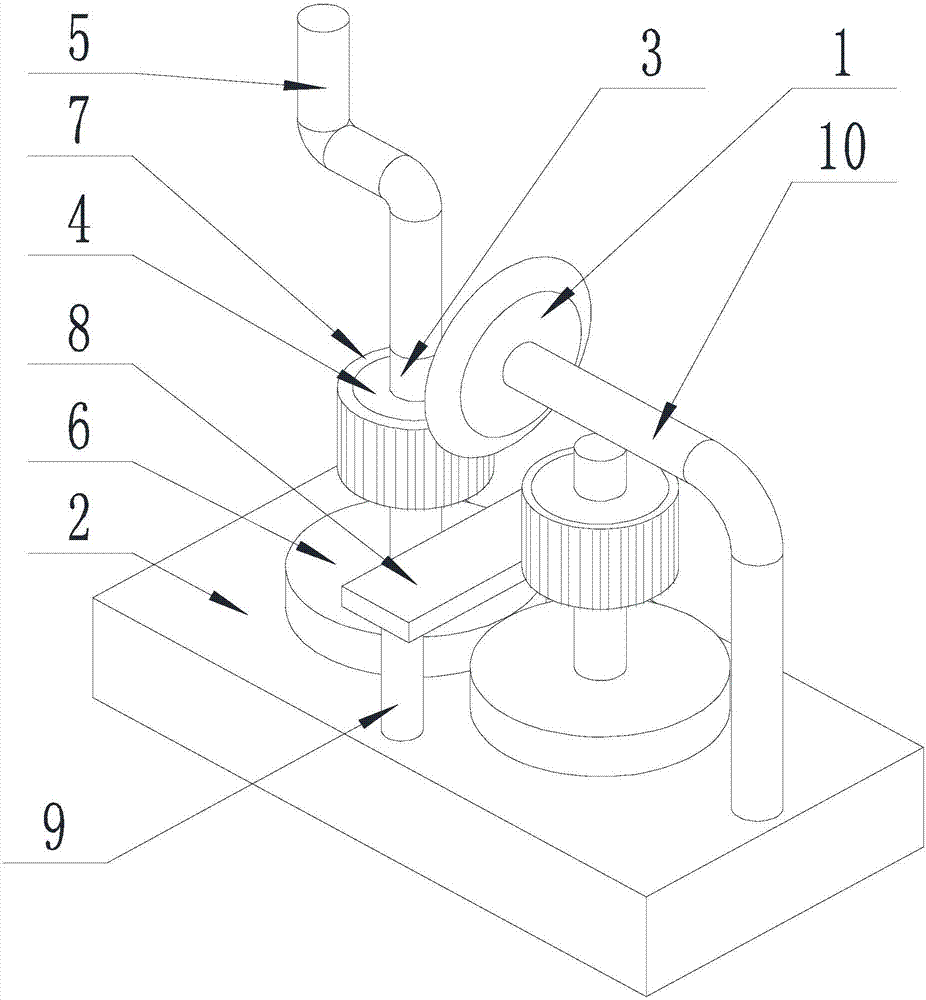

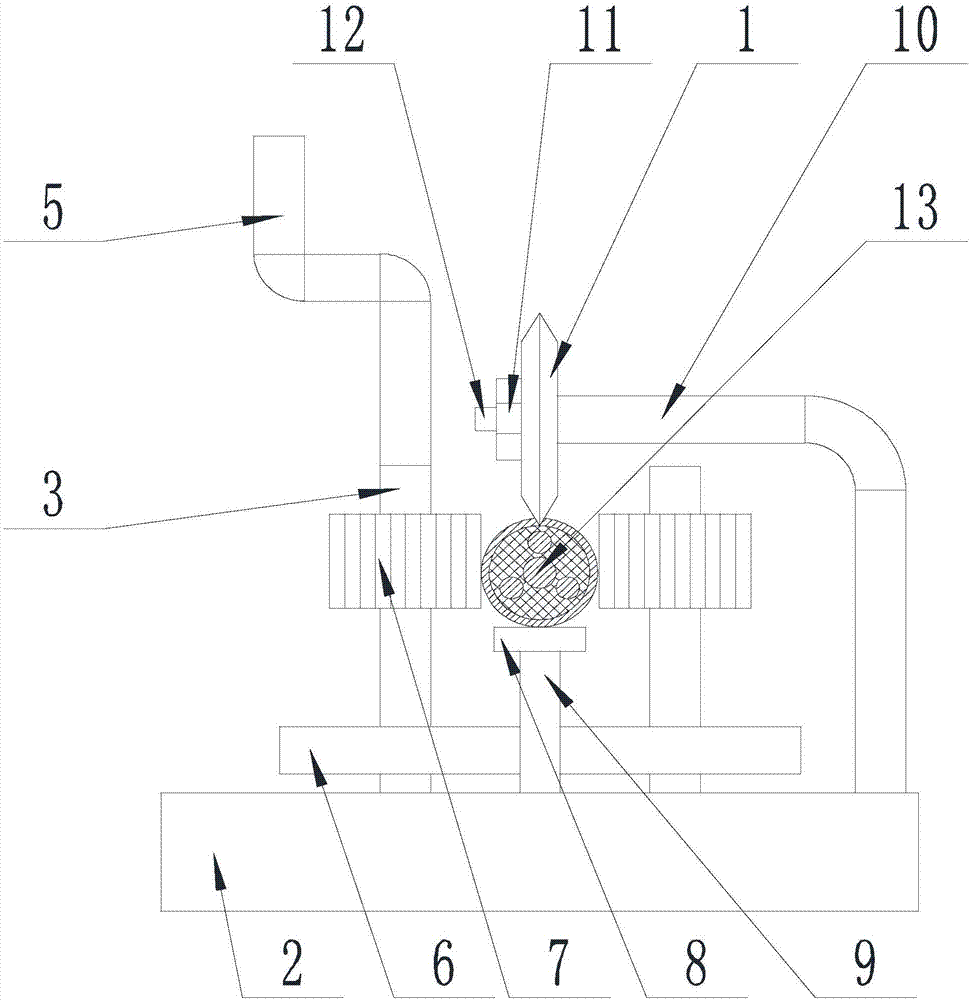

[0036] Such as Figure 1-Figure 2 As shown, the mechanism for stripping the cable insulation coating of the present invention includes a push assembly, a cutter 1 and a fixing plate 2, the push assembly includes a connecting shaft 3 and a push piece 4, and one end of the connection shaft 3 passes through the push piece After 4, it is rotationally connected with the fixed plate 2, and the propulsion member 4 is cylindrical, and its axis coincides with the axis of the connecting shaft 3;

[0037] There are two propulsion assemblies, and a handle 5 is provided on the connecting shaft 3 of one of the propulsion assemblies away from the fixed plate 2;

[0038] The cutter 1 is fixed on the top of the fixed plate 2 by a support rod 10, and the cutter 1 is positioned between the propulsion assemblies, and the distance between the cutter and the two propulsion assemblies is equal; the cutter 1 is a disk, and its axis is perpendicular to the two The axes of the two connecting shafts 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com