Heavy calcium carbonate slurry dewatering and drying method

A dehydration technology for heavy calcium carbonate and slurry, which is applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. It can solve the problem that the particle size of dry grinding products cannot reach the particle size of high-end products Requirements, failure to solve the problems of low solid content grinding and grading of slurry, low-end product quality is not stable enough, etc., to achieve the effect of preventing bridging, reducing process cost, and stabilizing slurry flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

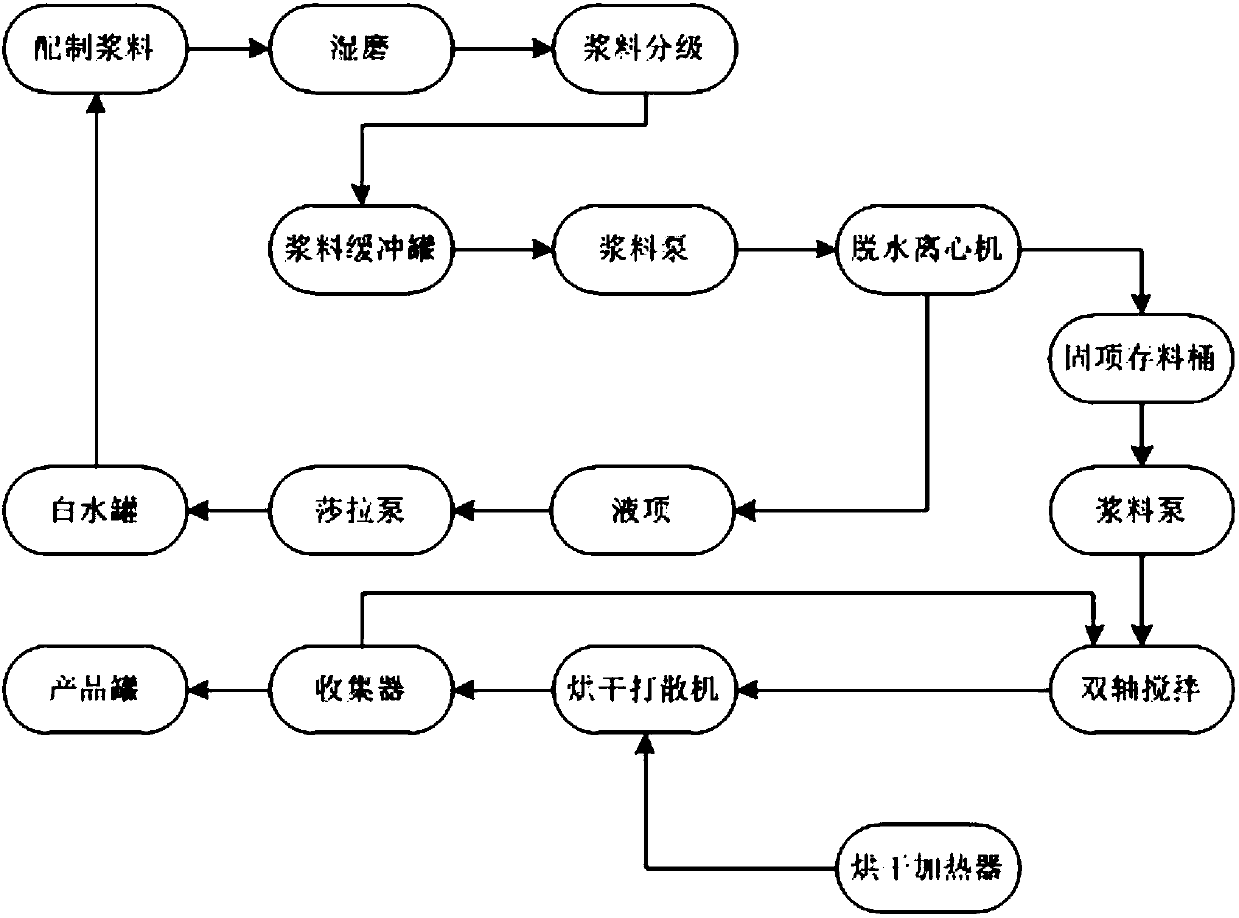

[0027] like figure 1 Shown, a kind of heavy calcium carbonate slurry dehydration drying method comprises the following steps

[0028] a) preparation slurry: solid calcium carbonate is mixed with water, is mixed with the slurry that calcium carbonate content is 20%;

[0029] b) Wet grinding: the slurry is ground by wet grinding to obtain a primary slurry, the calcium carbonate content of the primary slurry is 30%, -2um 30%, +25um25ppm;

[0030] c) Classification: make the primary slurry enter the separator for separation, separate the secondary slurry, the calcium carbonate content of the secondary slurry is 25%, -2um 40%, +25um 5ppm;

[0031] d) Centrifugal dehydration: The graded secondary slurry passes through a 500-mesh vibrating screen, and the sieved slurry is pumped into the slurry buffer tank by the slurry pump. The temperature of the sieved slurry is 40°C, and the dehydration centrifuge is started. The rotation speed is 1700rpm, the feed rate is 5500L / h, the slurry i...

Embodiment 2

[0034] like figure 1 Shown, a kind of heavy calcium carbonate slurry dehydration drying method comprises the following steps

[0035] a) preparation slurry: solid calcium carbonate powder is mixed with water, is mixed with the slurry that calcium carbonate solid content is 25%;

[0036] b) Wet grinding: the slurry is ground by wet grinding to obtain a primary slurry, the solid content of calcium carbonate in the primary slurry is 37.5%, -2um45%, +25um32ppm;

[0037] c) Classification: make the primary slurry enter the separator for separation, separate the secondary slurry, the solid content of calcium carbonate in the secondary slurry is 28%, -2um 55%, +25um 10ppm;

[0038] d) Centrifugal dehydration: The graded secondary slurry is passed through a 500-mesh vibrating screen, and the sieved slurry is pumped into the slurry buffer tank by the slurry pump, and the temperature of the sieved slurry is 42°C; start the dehydration centrifuge, and the dehydration centrifuge The rot...

Embodiment 3

[0041] like figure 1 Shown, a kind of heavy calcium carbonate slurry dehydration drying method comprises the following steps

[0042] a) preparation slurry: solid calcium carbonate is mixed with water, is mixed with the slurry that calcium carbonate solid content is 35%;

[0043] b) Wet grinding: the slurry is ground by wet grinding to obtain a first-grade slurry with a calcium carbonate solid content of 40%, -2um 60%, +25um 40ppm;

[0044] c) Classification: make the primary slurry enter the separator for separation, separate the secondary slurry, the solid content of calcium carbonate in the secondary slurry is 30%, -2um 70%, +25um 15ppm;

[0045]d) Centrifugal dehydration: the graded secondary slurry passes through a 500-mesh vibrating screen, and the sieved slurry is pumped into the slurry buffer tank by the slurry pump, and the temperature of the sieved slurry is 45°C; start the dehydration centrifuge, and the dehydration centrifuge The rotation speed is 2100rpm, the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com