Precise positioning system of lifting appliance

A precise positioning and lifting technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problem of long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

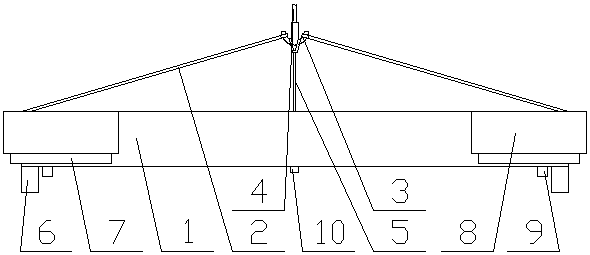

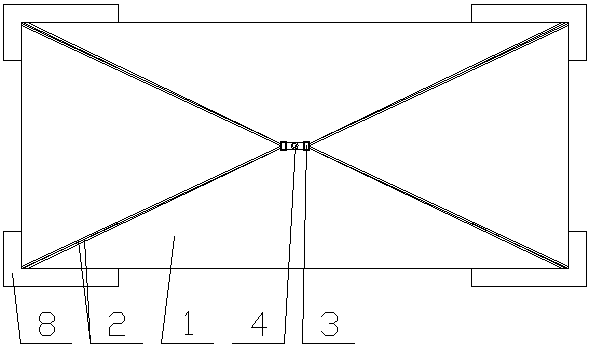

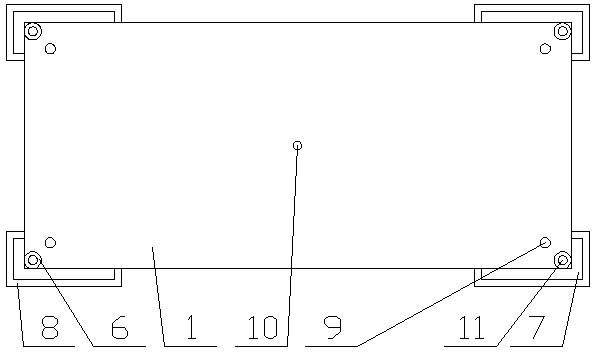

[0080] combine Figure 1~Figure 4 It can be seen that the present invention includes a spreader body 1, the length and width of the spreader body 1 match the container, the top of the spreader body 1 is fixed with the sling 4 of the crane, and the side wall of the spreader body 1 The four corners are respectively connected with positioning auxiliary boards 7 up and down, and the positioning auxiliary boards 7 are vertical plates of "L" shape structure. The four corners of the bottom of the spreader body 1 are also provided with twist locks 6 and ultrasonic receiving modules 9 respectively. , the center of the bottom of the spreader body 1 is provided with a laser distance measuring module 10, the spreader body 1 is also provided with a temperature sensor, and also includes an ultrasonic emission module set on the top of the container and a controller in the crane cockpit and a display, the laser ranging module 10, the ultrasonic receiving module 9, the temperature sensor and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com