Blocking prevention star-shaped feeding device and feeding method

A feeding device and anti-jamming technology, which is applied in the field of metallurgy, can solve problems such as the rotor cannot rotate, the material is jammed, and the star feeder cannot operate normally, so as to achieve the effect of solving the jammed material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following describes the specific implementations of the present invention in more detail with reference to the accompanying drawings and embodiments, so as to better understand the solutions of the present invention and the advantages of various aspects thereof. However, the specific embodiments and examples described below are only for illustrative purposes, rather than limiting the present invention.

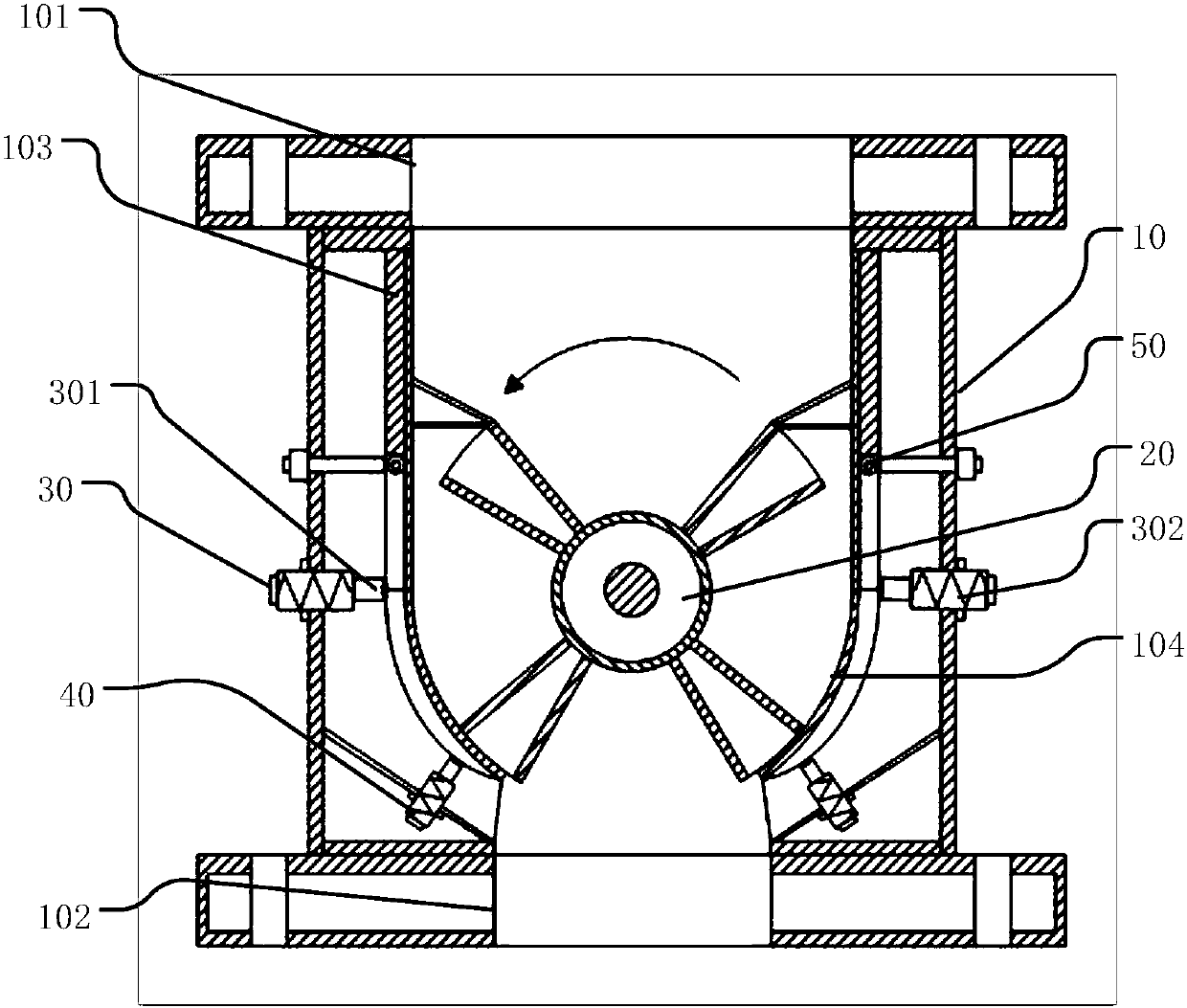

[0040] Such as figure 1 As shown, the jam-proof star feeding device of the present invention includes a frame 10, a rotor 20 and an jam-proof device 30. The frame is provided with an inlet 101, an outlet 102 and a symmetrical feeding trough 103. The rotor 20 is placed in the feeding trough 103 and is driven to rotate by a driving mechanism. The rotor 20 is provided with blades along the circumferential direction. The rotation axis of the rotor 20 is perpendicular to the central axis of the feeding trough 103. The feeding trough 103 is equally divided into independent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com