A convenient traction plastic pipe handling equipment

A technology for handling equipment and plastic pipes, which is applied to traction connectors, support parts, vehicle parts, etc., can solve the problems of poor handling stability, complicated handling operations, and easy falling of pipe fittings, and achieves improved handling efficiency, flexible and convenient fixing operation. , The effect of high stability of handling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

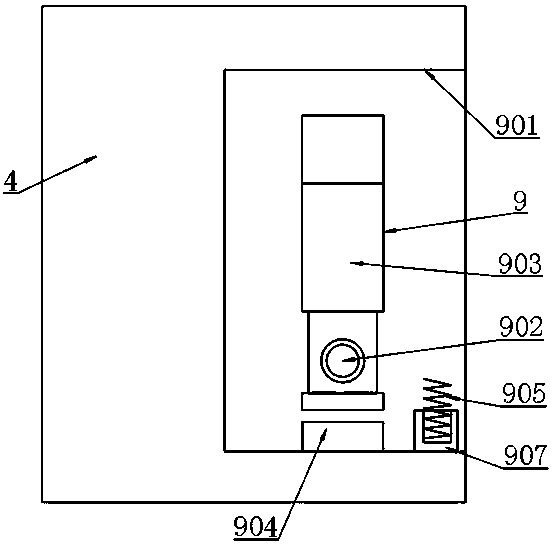

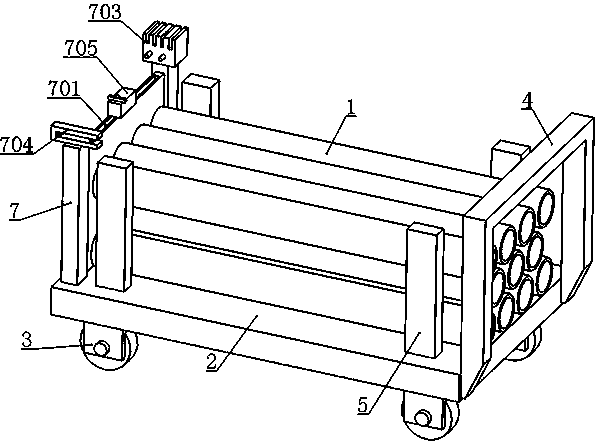

[0026] Example: as attached figure 1 , 2 , 3, 4, 5, 6, 7 and attached Figure 8 As shown, a convenient traction plastic pipe fitting handling equipment includes a base plate 2 for placing plastic pipe fittings 1, a roller 3 arranged on the base plate 2, a push handle 4, and a fixed column set 5, and also includes a set One end of the plastic pipe fitting 1 is opened and clamped to fix the clamping unit 6 of the plastic pipe fitting 1, and it is arranged on the side of the bottom plate 2 away from the push handle 4 and is attracted by magnetic force. The electromagnet unit 7 used to fix the clamping unit 6 is formed between the electromagnet unit 7 and the clamping unit 6 for jacking up and opening the clamping unit 6 for clamping and fixing the pipe fittings The repulsive magnetic field of the operation, the push handle 4 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com