Wafer centering device for measurement apparatus

A technology of centering device and measuring instrument, which is applied in the direction of grinding device, semiconductor/solid-state device testing/measurement, large-scale fixed member, etc., which can solve the problem of high error rate of measuring instrument, frequent wafer centering error, and reduced operation rate of CMP equipment, etc. problem, to solve the centering error and improve the operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

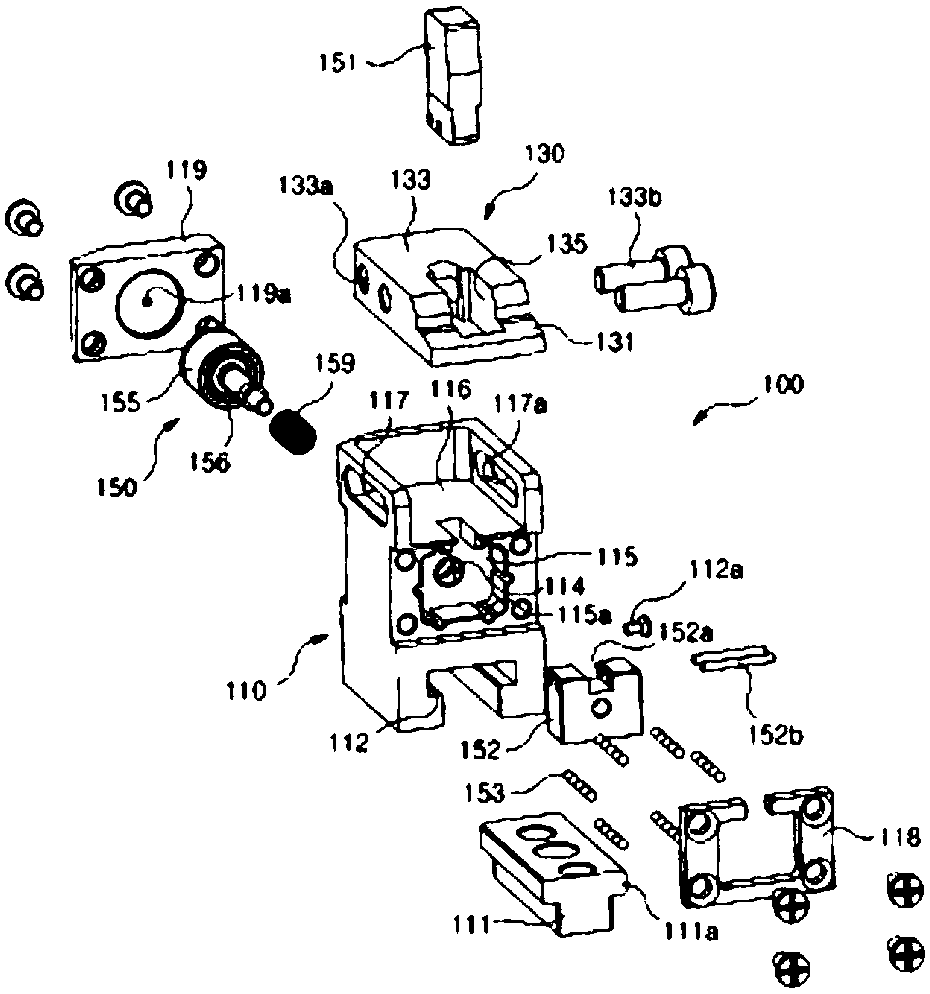

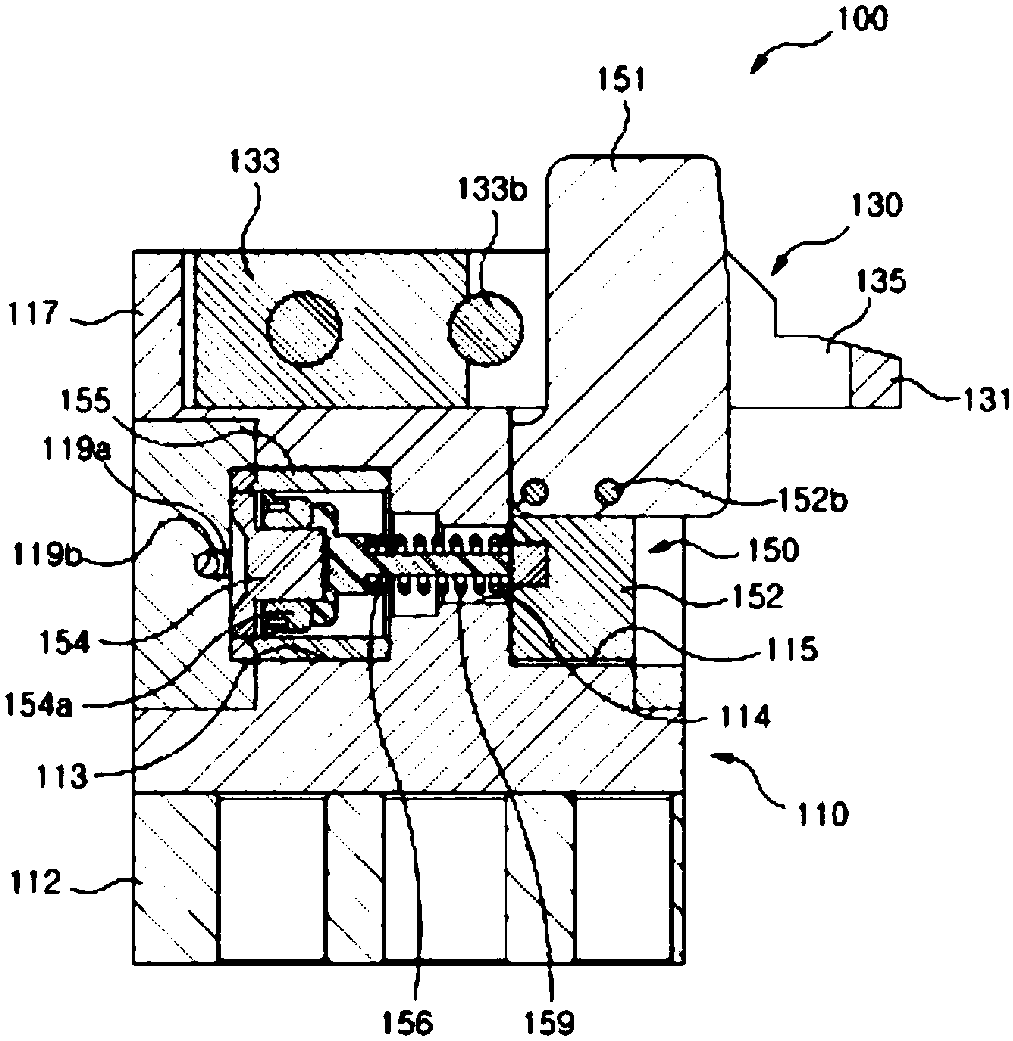

[0026] A wafer centering device for a measuring instrument according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. In this specification, the same and similar reference signs are attached|subjected to the same and similar structure.

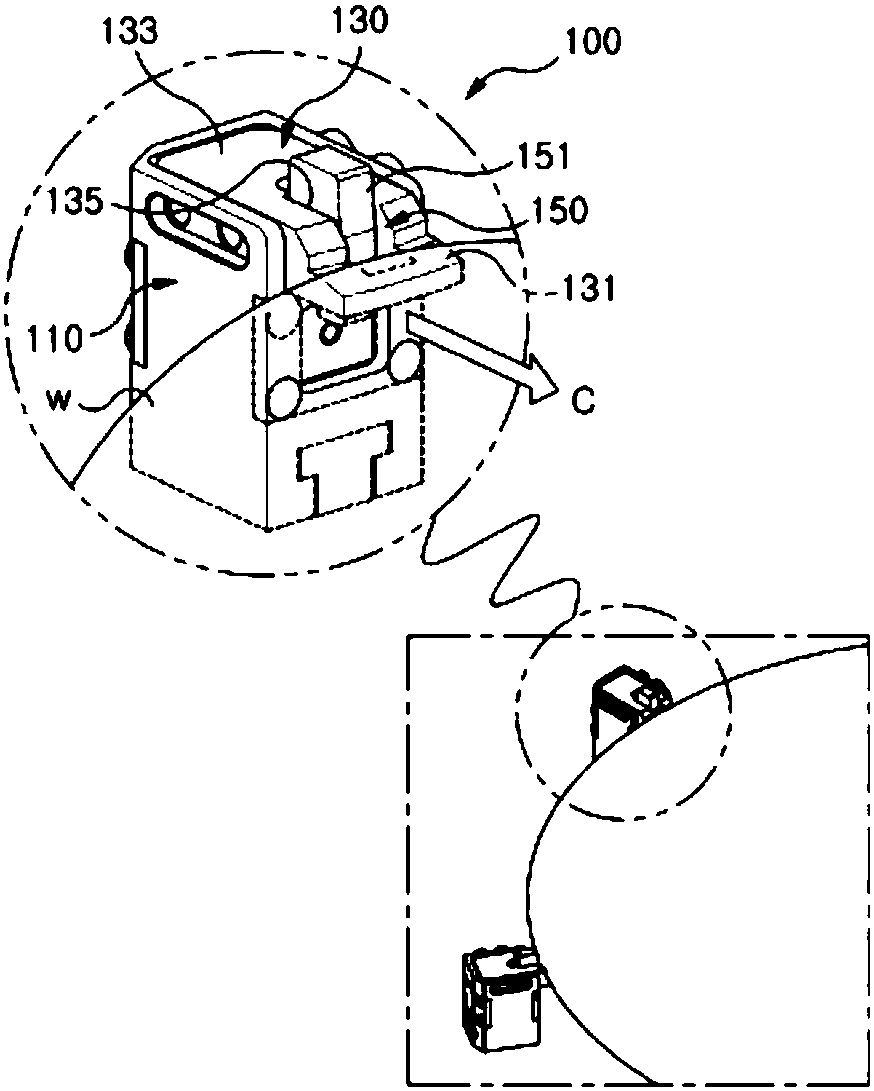

[0027] figure 1 It is a perspective view showing a state in which a wafer W is supported by the wafer centering device 100 for a measuring instrument according to an embodiment of the present invention.

[0028] Referring to the drawings, the wafer centering apparatus 100 may have a body unit 110 , a guide unit 130 and a shift unit 150 .

[0029] The body unit 110 is installed on the CMP equipment. A guide unit 130 and a displacement unit 150 are provided on the body unit 110 .

[0030] The guide unit 130 supports the wafer W, and guides the operation of the shift unit 150 . Specifically, the guide unit 130 may have a support part 131 , a mounting part 133 and a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com