Fuel composition

A composition and fuel technology, applied in the direction of fuel, fuel additive, liquid carbon-containing fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

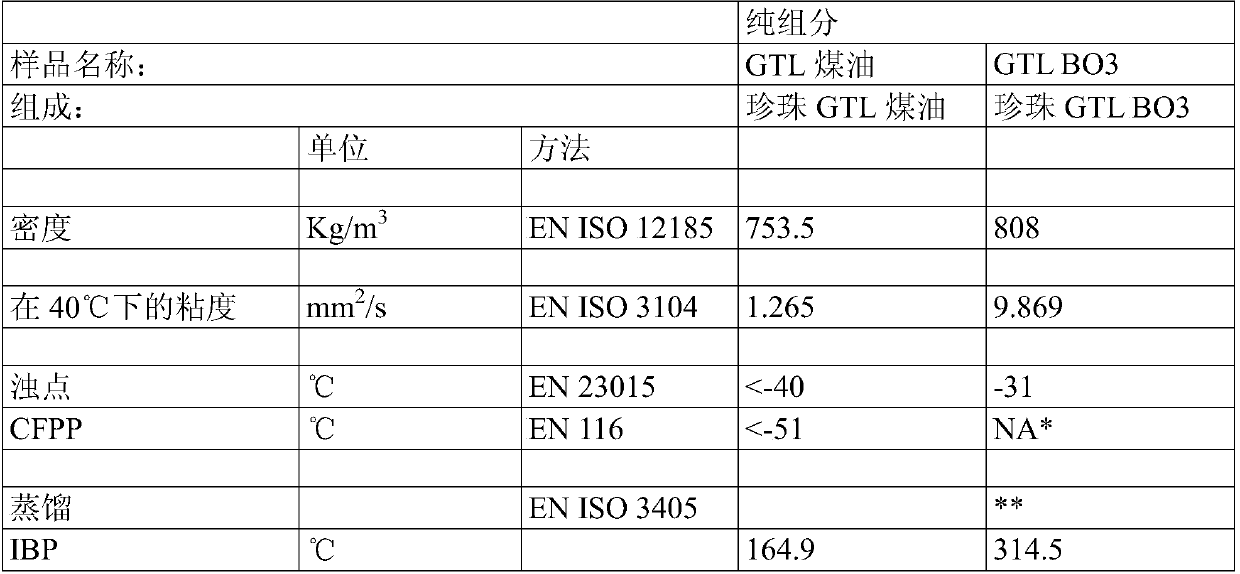

[0075] Various fuel blends were produced with the compositions shown in Table 2 below. Table 1 shows the physical characteristics of the GTL kerosene and GTL base oil (GTL BO3) used in the blend. Both GTL kerosene and GTL base oil (GTL BO3) were obtained from Pearl GTL, Ras Laffan (Pearl GTL, Ras Laffan) and are commercially available from the Shell / Royal Dutch group of companies. The physical characteristics of the conventional diesel fuel (Diesel B0) used in the blend are shown in Table 2. "Diesel B0" as used herein means a diesel base fuel containing 0% biofuel components.

[0076] Various measurements of the final blends were made using the test methods set forth in Table 2, including density, viscosity, cloud point, and CFPP measurements.

[0077] Table 1

[0078]

[0079]

[0080] *The viscosity of GTL BO3 is outside the range of CFPP test.

[0081] **For GTL BO3, distillation data are from simulated distillation (GC) instead of EN ISO 3405.

[0082] Table...

example 1

[0087] As can be seen from Table 2, in order to lower the cloud point of diesel B0, 20% of GTL kerosene (blend 1) was added. This lowered the cloud point from -4.6°C to -7.7°C. However, the density has also been reduced to 823.7kg / m 3 And the viscosity is reduced to 2.149mm 2 / s. These are close to 820kg / m 3 density and 2mm 2 The EN 590 specification minimum requirement for a viscosity of / s. If further addition of GTL kerosene is required to further lower the cloud point, the density and viscosity of the blend is further reduced and falls below the minimum specification requirements - see Blend 2 with 30% GTL kerosene. If instead of adding 30% GTL kerosene, 10% GTL BO3 plus 20% GTL kerosene is added (blend 5), then a lower cloud point is obtained than blend 1 (-8.4°C vs -7.7°C), but the density and viscosity Stay above the minimum specification requirements.

example 2

[0089] As can be seen from Table 2, in order to lower the cloud point of diesel B0, 20% kerosene was added (blend 1). This lowered the cloud point from -4.6°C to -7.7°C. However, the density has also been reduced to 823.7kg / m 3 And the viscosity is reduced to 2.149mm 2 / s. These are close to 820kg / m 3 density and 2mm 2 The specification minimum requirement for a viscosity of / s. If instead of adding 20% GTL kerosene, 13.33% GTL kerosene plus 6.66% GTL BO3 (blend 3) is added, then a similar reduction in cloud point and CFPP is still obtained, but with a significantly higher viscosity, which can provide the power benefits of a diesel engine .

[0090] The present invention has the key advantage of allowing cloud point and CFPP properties to be improved while maintaining other properties such as viscosity and density within diesel fuel specification requirements (eg EN590).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com