Linear-type guide horizontal position assembly for bag-sewing machine

A kind of sewing machine, linear technology, applied in the field of sewing machine, can solve the problem of forming line position deviation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

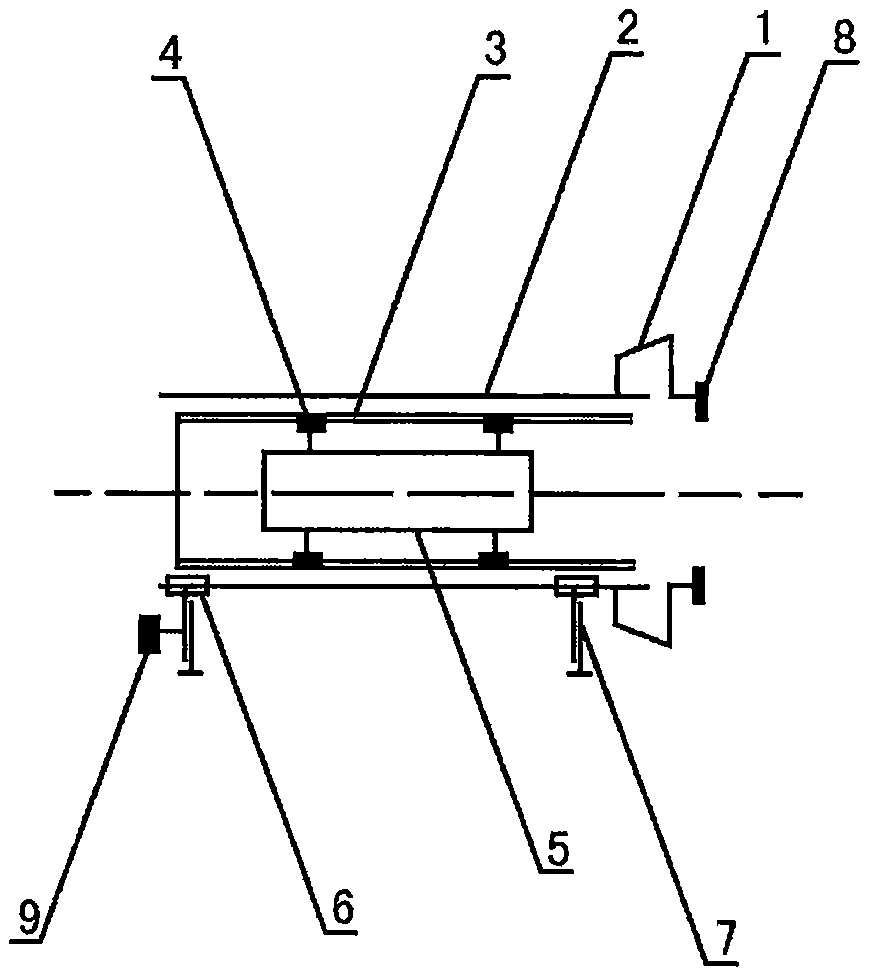

[0012] Embodiment: as shown in the accompanying drawing. A linear guide leveling assembly for a bag sewing machine, comprising a frame body (1), the frame body (1) is designed in a horizontally parallel structure as a whole, and includes a clamping plate device (2), an inner rail device (3), a guide module (4 ), the positioning card slot (5), the bottom is provided with lifting parts including the regulator (6), the telescopic bracket (7), the buckle device (8) is located at the front end of the frame body (1), and the bag mouth is horizontally clamped into the frame when in use Inside the body (1), clamp and locate after adjusting the corresponding depth. At this time, the seam end of the bag sewing machine is located in the positioning slot (5), and the operator can perform parallel or longitudinal linear sewing according to the convenience of the operation.

[0013] A linear guiding and leveling assembly of a bag sewing machine is provided with a prompting device (9), which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com