High-speed stacking machine for bagged feed and stacking method thereof

A stacker and stacking technology, applied in the field of bagged feed high-speed stacker, can solve the problems of insufficient automation control, large occupied area and complex conveying line structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

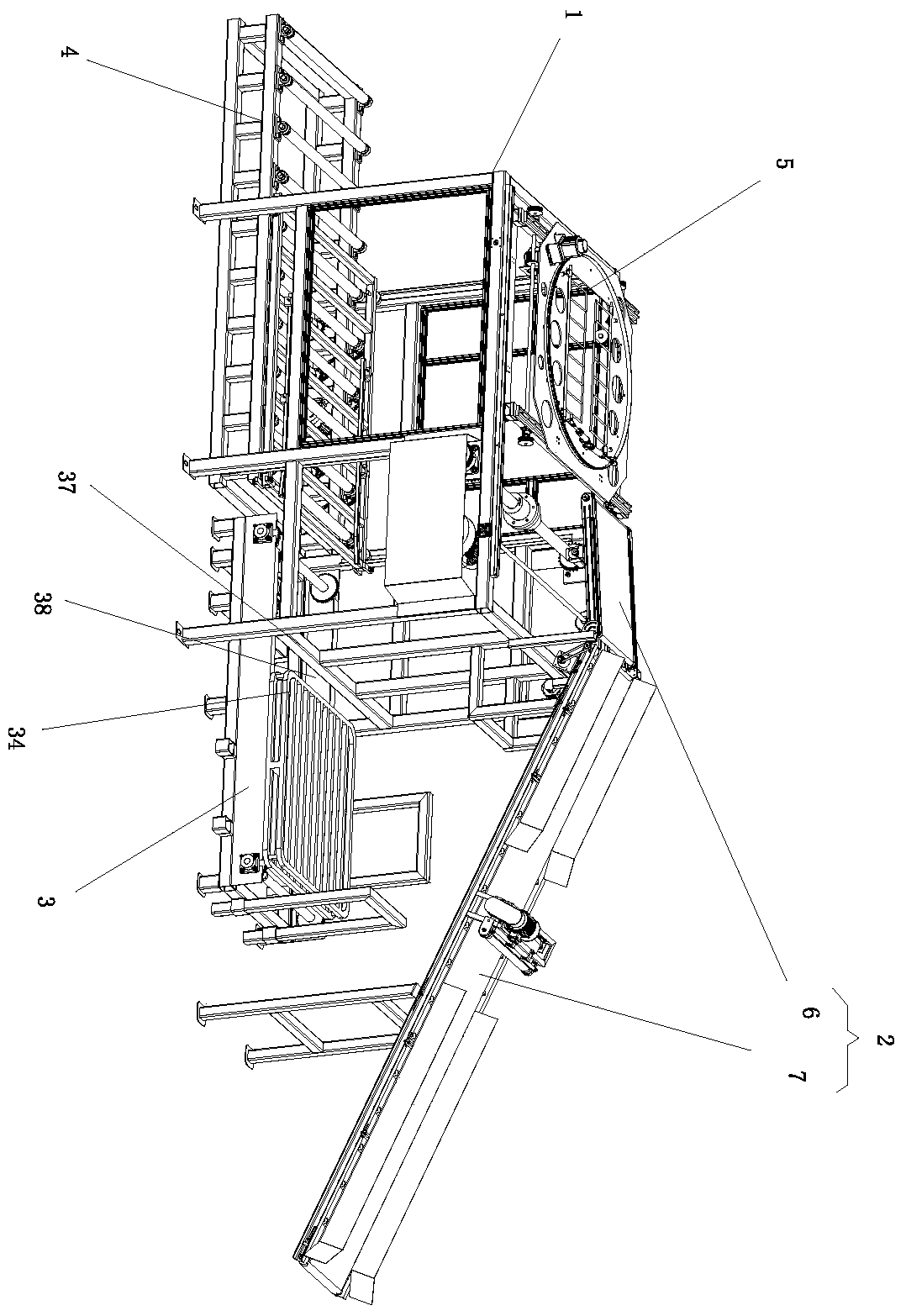

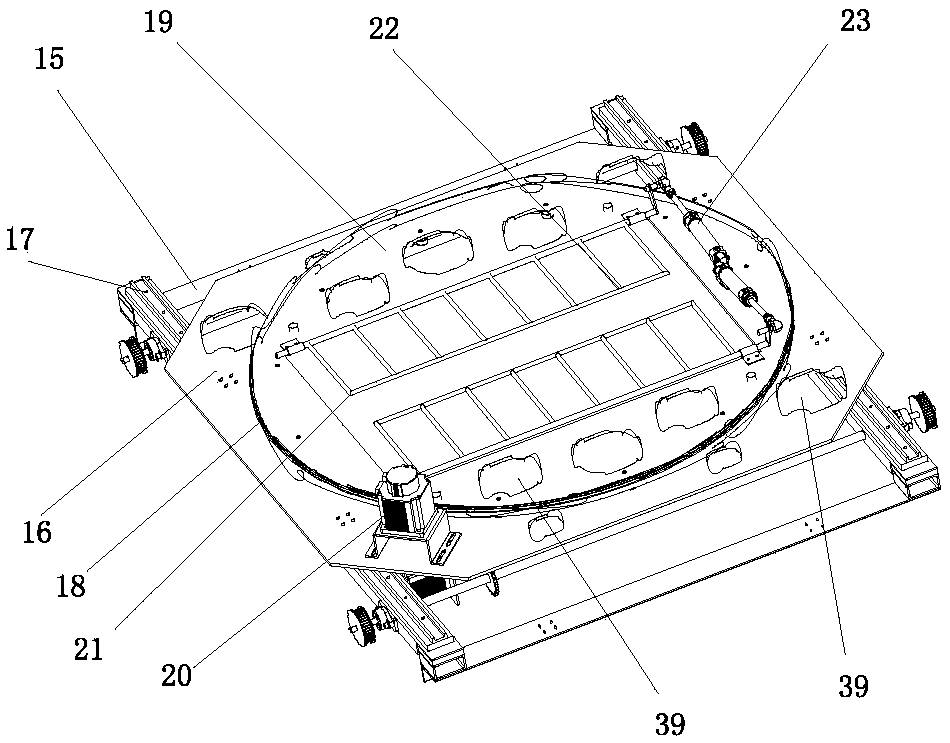

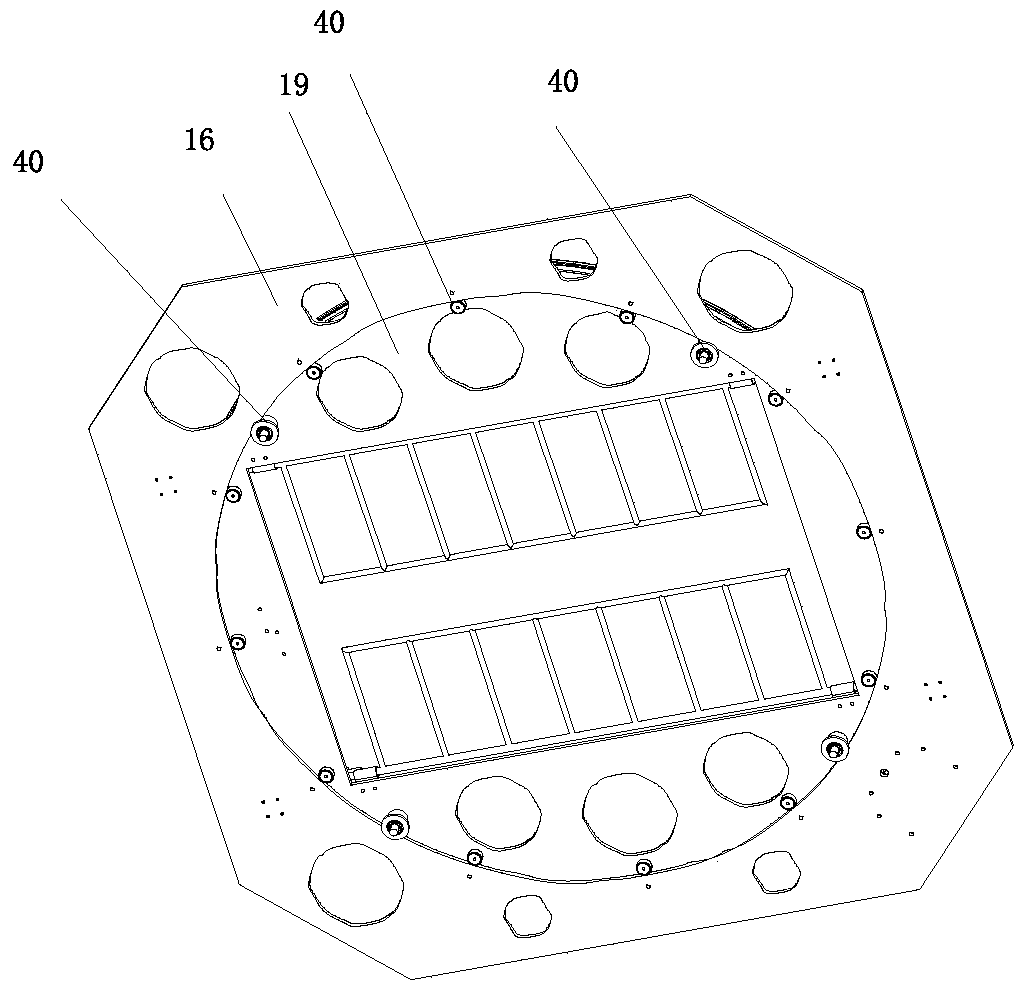

[0027] Depend on Figure 1 to Figure 7As shown, the present invention comprises a stacker frame 1, an automatic slideway device 2, an automatic pallet changing device 3 and an automatic pallet handling device 4, and the automatic slideway device 2 is connected with the stacker frame 1, and is stacked The upper end of the machine frame 1 is provided with a stacking mechanism 5, and the automatic slideway device 2 includes a first slideway body 6 and a second slideway body 7, the first slideway body 6 and the second slideway body 7 are in the form of V-shaped setting, the slideway outlet position of the first slideway body 6 is above the stacking mechanism 5, and a pressing device is provided on the second slideway body 7, and the pressing device includes a pressing material bracket 8. The binder bracket 8 is provided with a connecting frame 9, and the connecting frame 9 is provided with two second rollers 10 arranged in parallel, the two second rollers 10 are covered with a bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com