Automatic assembling and detecting device and technological method for FPC connector

A technology for automatic assembly and testing equipment, applied in the assembly/disassembly, connection, circuit/collector parts and other directions of contacts, which can solve the problems of frequent safety accidents, low qualification rate, low production efficiency, etc. Safety accidents, simple process flow, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

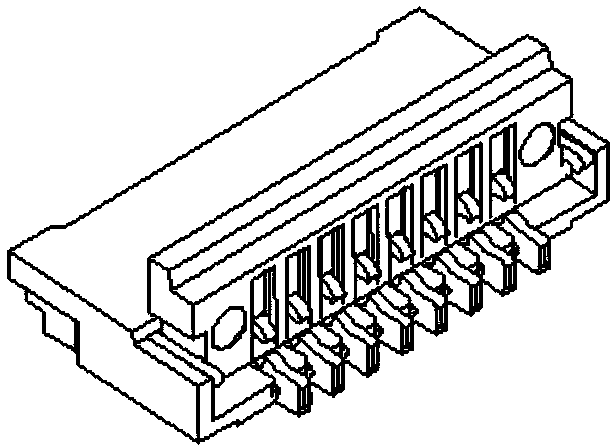

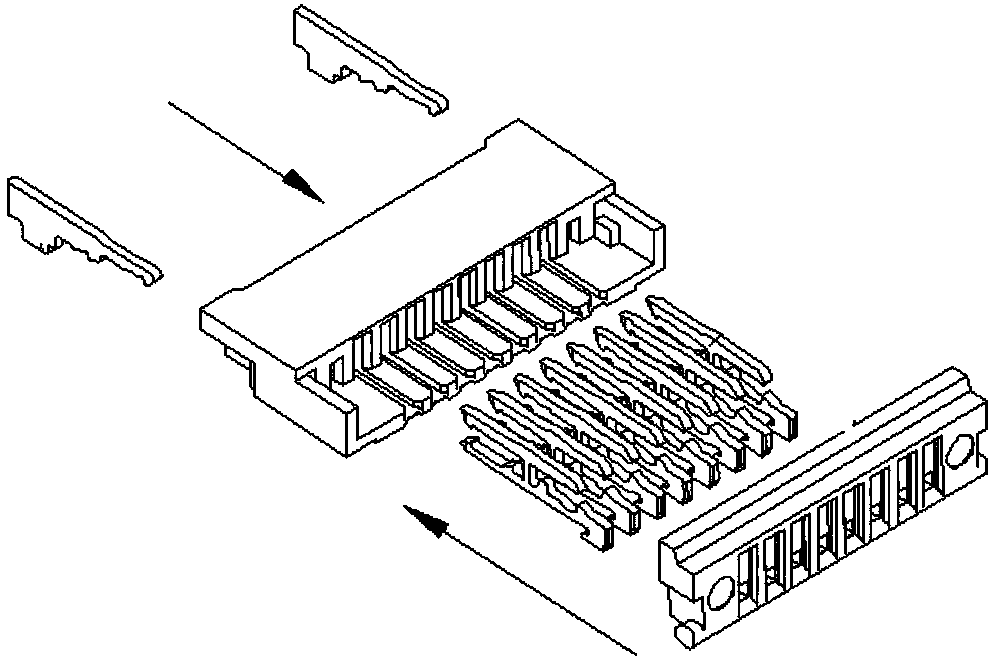

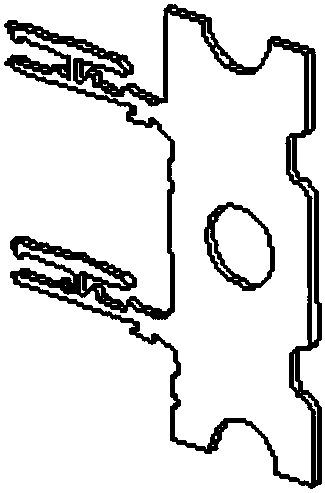

[0039] Combine Figure 1-16 , The FPC connector automatic assembly testing equipment of the present invention includes:

[0040] The first workbench 10 and the second workbench 11, one side of the first workbench 10 and the second workbench 11 are hinged, and the first workbench 10 is provided with a main body feeding device 1, a quick-plug terminal device 2, The plug-in cover device 3, the quick-insertion buckle device 4, and the workpiece transfer device 7, the main body feeding device 1, the quick-insertion terminal device 2, the plug-in cover device 3, and the quick-insertion buckle device 4 respectively pass through the workpiece transfer device 7 in sequence. The second workbench 11 is sequentially connected with a cover turning device 5, a visual inspection device 6 and a braid packaging device 8, and one end of the cover turning device 5 is connected with the workpiece transfer device 7. The first workbench 10 and the second A control display device 9 is also provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com