Core adjusting bracket

A core-adjusting and hole-adjusting technology, applied in the field of brackets, can solve the problems of inability to align end faces, cumbersome and complicated work of end face alignment, time-consuming and labor-intensive, etc., and achieves the effect of concrete structure and convenient industrialized processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

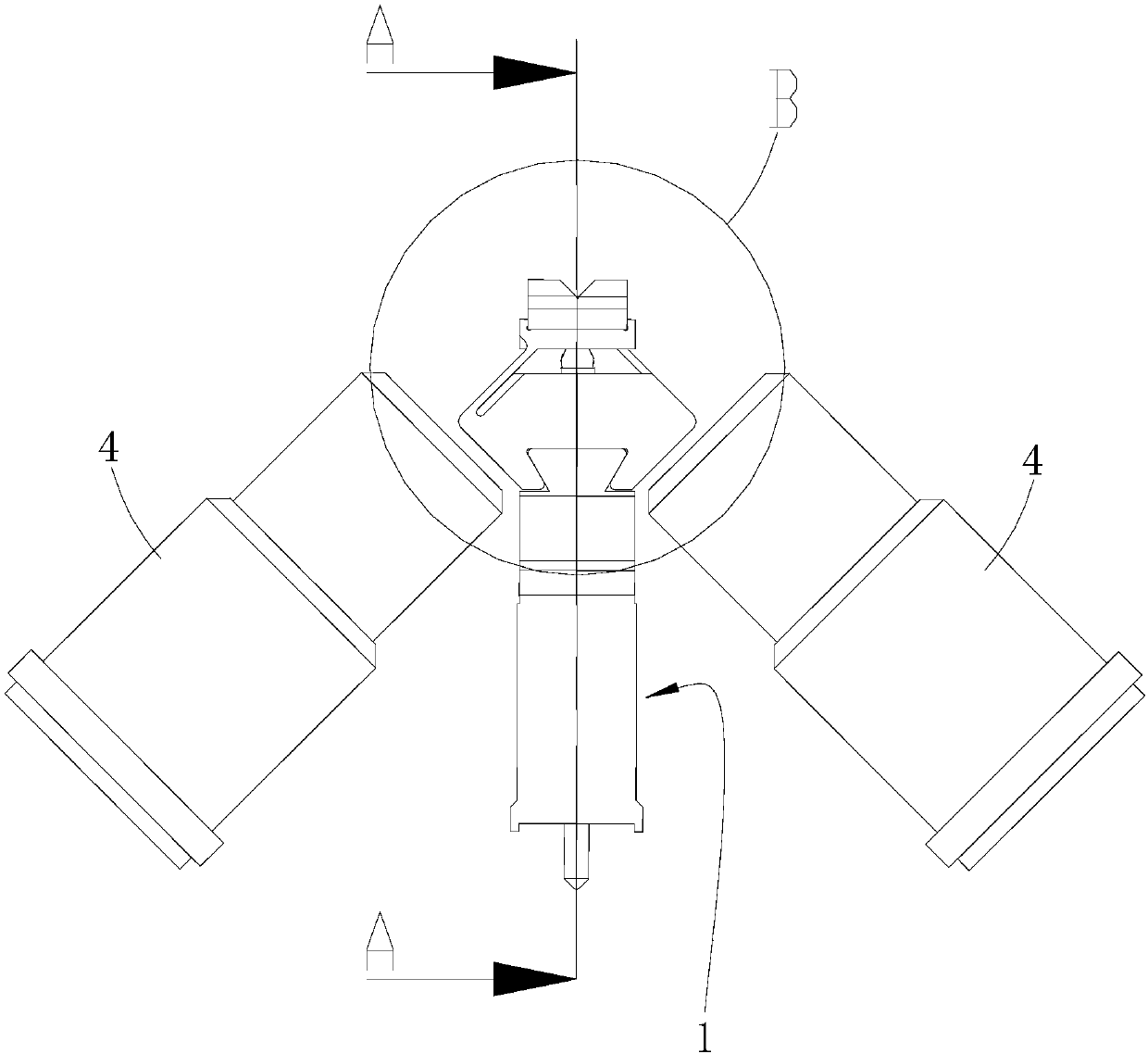

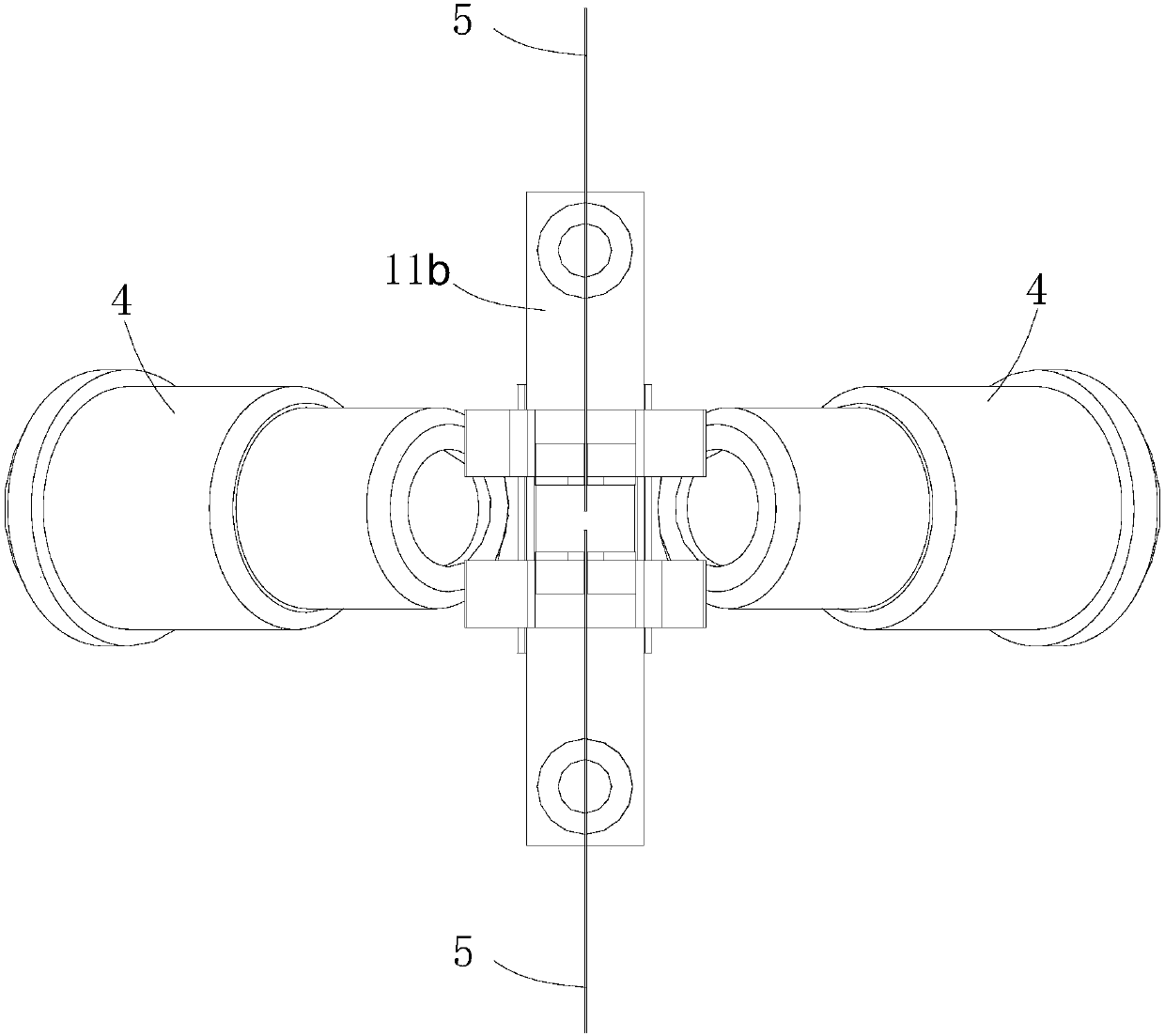

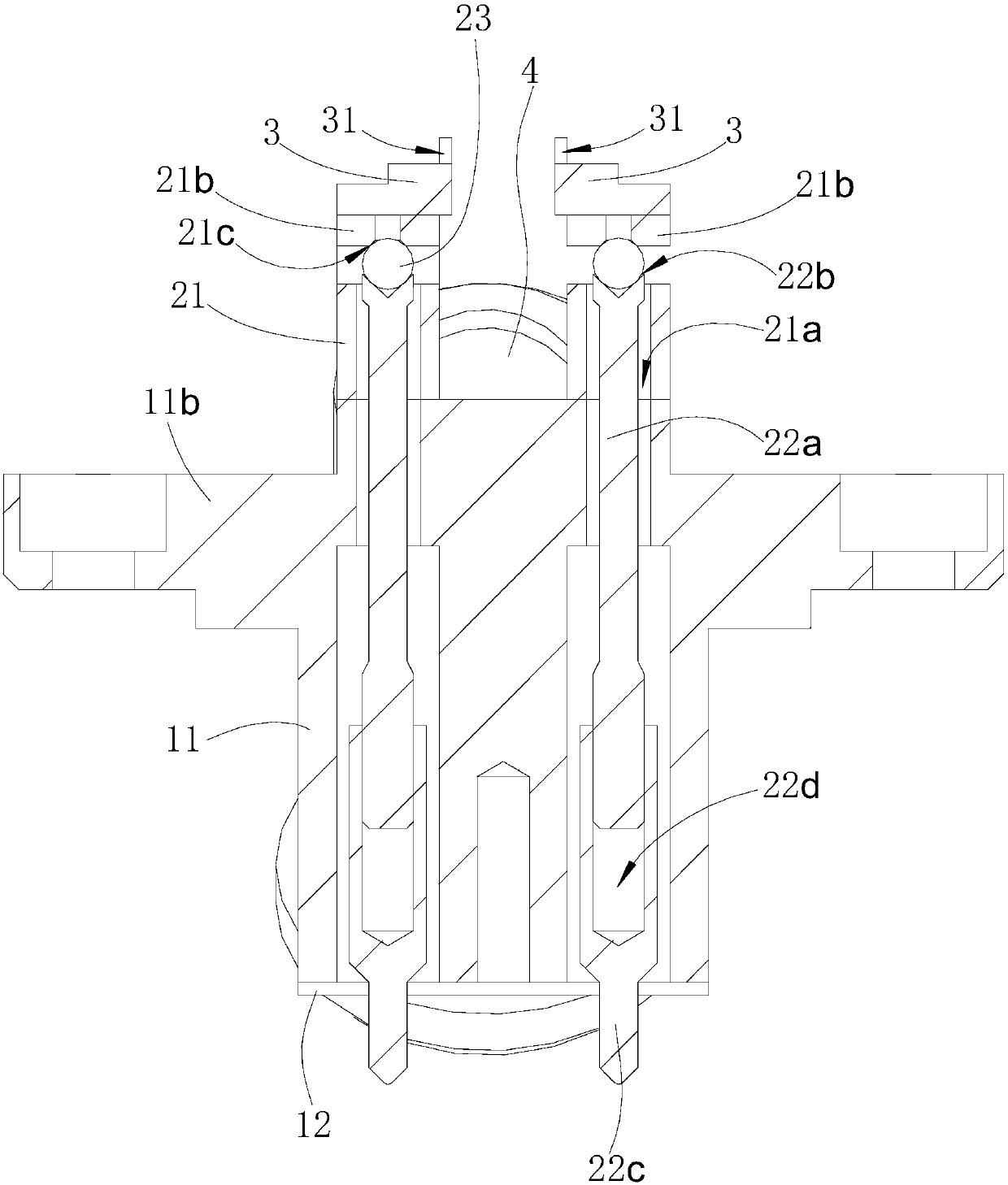

[0019] Such as Figures 1 to 5 as shown ( Figure 5 The section direction of image 3 same section direction)

[0020] The alignment bracket includes a housing 1 , two sets of adjustment components and two sets of optical fiber positioning blocks 3 .

[0021] The housing 1 includes a housing body 11 and an installation baffle 12. The housing body 11 is provided with two first adjustment stage holes 11a that pass through its upper and lower end surfaces. The installation baffle 12 corresponds to the position of the first adjustment stage hole 11a of the housing body 11. There are two second adjustment stage holes 12a, and the installation baffle 12 is at the lower part of the shell body 11 through fastening screws (not shown in the figure), and the first adjustment stage hole 11a of the shell body 11 corresponds to the first adjustment stage 12 of the installation baffle 12 The two adjustment stage holes 12a together form the adjustment hole of the housing 1, and the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com