Outdoor optical cable welding emergency overhaul room

A technology for maintenance rooms and optical cables, applied in industrial buildings and other directions, can solve problems such as inability to operate in the field, and achieve the effects of flexible and convenient telescopic adjustment, improved working environment, and flexible height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but this does not constitute a limitation to the protection scope of the claims of the present invention.

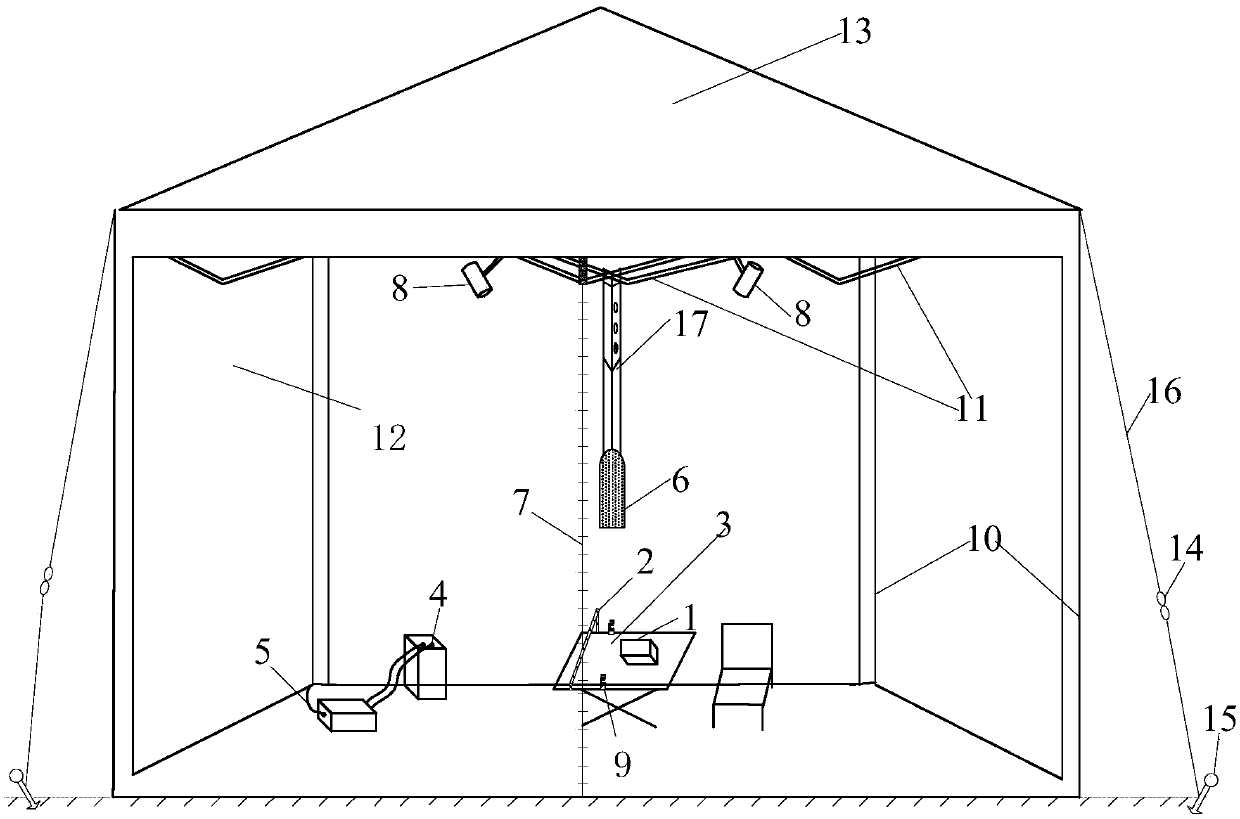

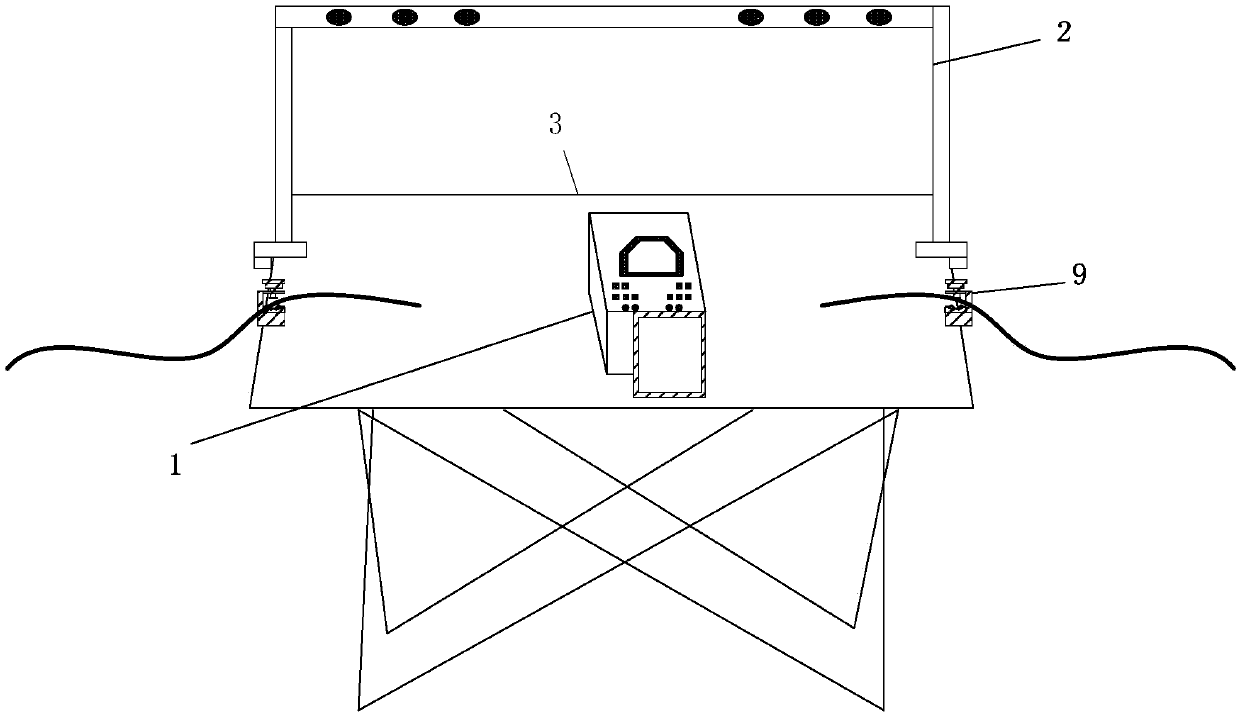

[0026] Such as figure 1 As shown, the outdoor optical cable fusion emergency maintenance room of the present invention is a detachable portable emergency maintenance room, including the following components:

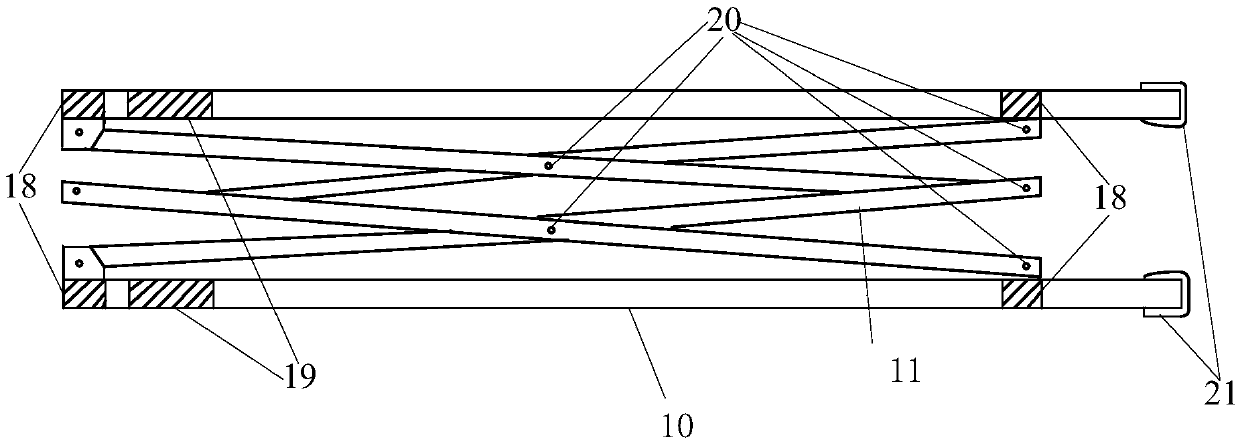

[0027] The main structure of the emergency maintenance room: the main structure of the maintenance room is a support frame, which is composed of a top frame 11 connected to four columns 10 respectively. The top frame 11 adopts a foldable scissor structure. Buckle-type positioning telescopic, can realize the three-level height adjustment of 2 meters, 1.8 meters, 1.5 meters in the maintenance room, to meet the needs of operators of different heights. Velcro 19 is provided on the outside of the column 10, and the bottom of the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com