Automobile interior ceiling with high strength and high sound absorption performance and preparation method thereof

A car roof and polyurethane technology, applied in chemical instruments and methods, vehicle parts, lamination, etc., can solve the problems of high cost, low sound absorption performance and other problems, achieve enhanced absorption, improve air permeability and sound absorption performance, and improve qualified products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, for better understanding and implementation, the following specific embodiments are given in conjunction with the accompanying drawings to describe the present invention in detail; the given embodiments are only used to explain the present invention, and are not intended to limit the scope of the present invention.

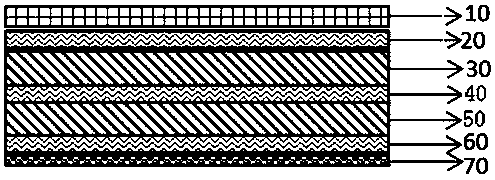

[0024] Example 1, see figure 1 , High-strength and high-sound-absorbing polyurethane car roof is prepared by the following process:

[0025] (1) Glue rolling: take the glass fiber mat and roll the glue on the glue rolling machine to make the glue glass layer. The glass fiber felt is a wet felt with a weight of 80g / m 2 ; The temperature of the rubber roller is 40°C, the height of the rubber roller is 1.5mm, and the amount of rubber rolled on each layer of glue glass is: the first layer is 17-23g / m 2 , the second layer 25-30 g / m 2 , the third layer 30-35g / m 2 ;The glue is environment-friendly moisture curing polyurethane glue;

[0026] (2) S...

Embodiment 2

[0032] Embodiment 2, same as embodiment 1, the difference is that the temperature of the rubber roller in the rubber rolling step is 15°C, and the height of the rubber roller is 1mm; the mold temperature in the pressing molding step is 100°C, the molding pressure is 9 MPa, and the molding dwell time 45s; the setting time of the cooling setting step is 30s; the cutting pressure of the robot water jet cutting step is 2500 Pa.

Embodiment 3

[0033] Embodiment 3, same as embodiment 1, the difference is that the temperature of the rubber roller in the rubber rolling step is 45°C, and the height of the rubber roller is 3mm; the mold temperature in the pressing molding step is 140°C, the molding pressure is 8 MPa, and the molding dwell time 30s; the setting time of the cooling setting step is 45s; the cutting pressure of the robot waterjet cutting step is 3500 Pa.

[0034] A high-strength and high-sound-absorbing polyurethane car roof and its preparation method according to the present invention, the plastic glass layer is made of glass fiber felt coated with environmental-friendly moisture-curing polyurethane glue of different grammes, and the density of the first PU layer is greater than that of the second PU layer Density, different densities can absorb noise in different frequency bands, effectively enhancing the sound absorption and noise reduction effect of the ceiling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com