Paper overturning machine and paper feeding mechanism thereof

A feeding mechanism and feeding technology, applied in the direction of turning objects, thin material processing, object supply, etc., can solve the problems of different paper sizes and weights, difficult paper transmission, and inability to overcome paper weight, etc., to achieve transmission efficiency and transmission. The effect of guaranteeing stability, improving production quality and improving the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

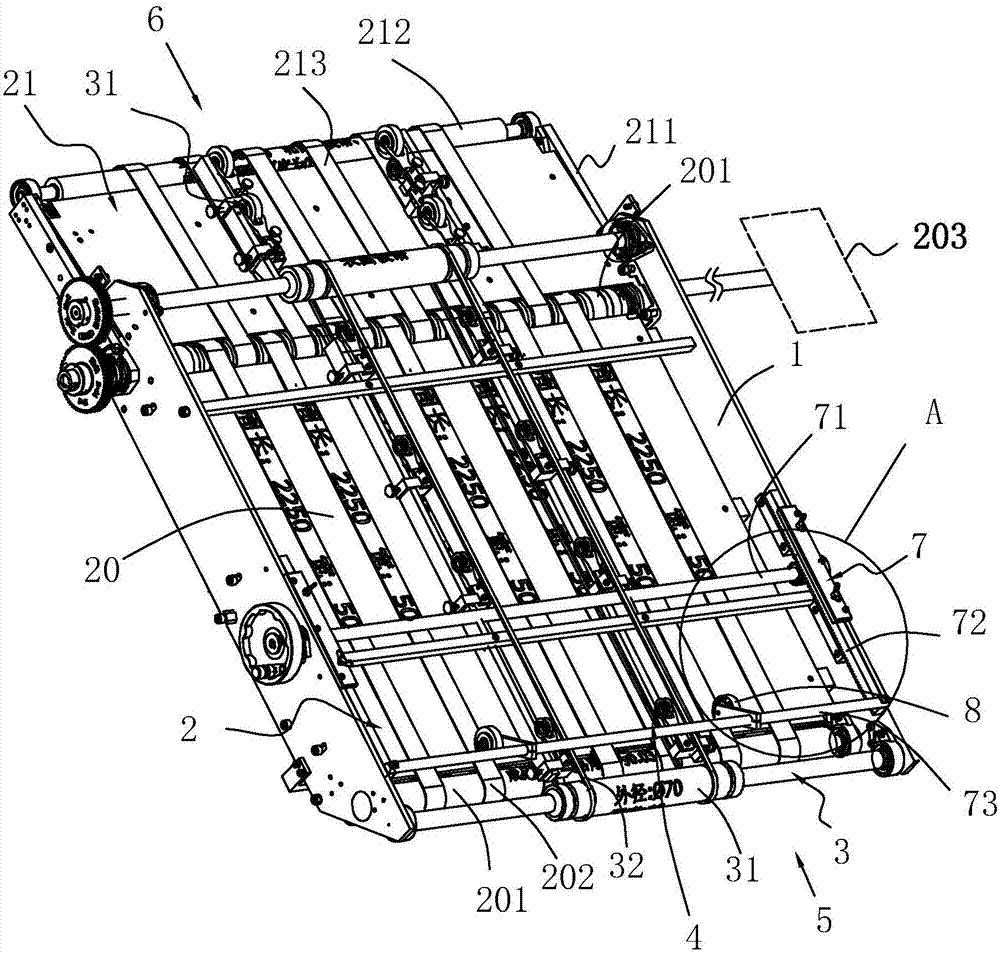

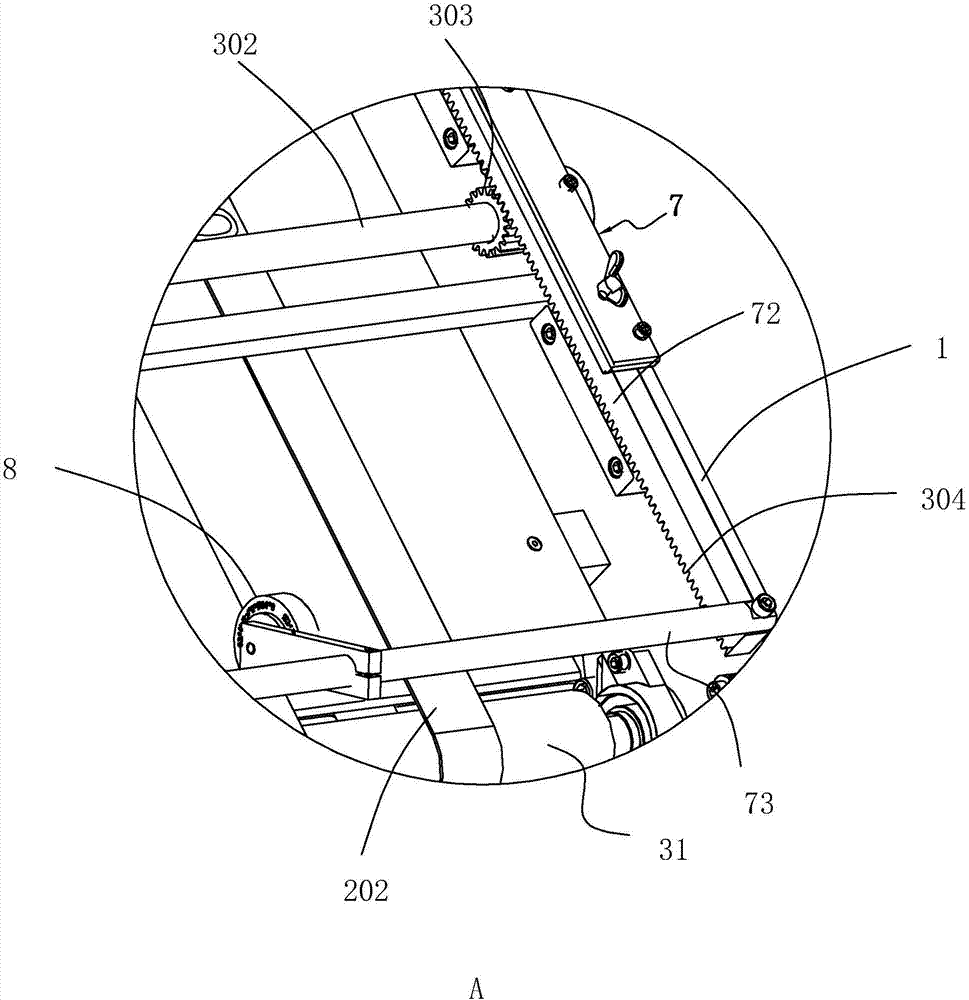

[0049] A paper feeding mechanism, see figure 1 , including a feed frame 1, a feed main transmission part 2 and a feed secondary transmission part 3 are installed in the feed frame 1, the feed secondary transmission part 3 is located above the feed main transmission part 2, and the feed main transmission part 2 and the feed auxiliary transmission part 3 will form a feed gap 4, and the two ends of the feed gap 4 are the paper feed end 5 and the paper discharge end 6 respectively; the paper enters the feed gap 4 from the paper feed end 5, and the paper The upper surface of the paper will be squeezed by the feeding auxiliary conveying part 3, and the lower surface of the paper will also be squeezed by the feeding main conveying part 2, and through the joint action of the feeding main conveying part 2 and the feeding auxiliary conveying part 3 , the paper will be transported from the paper input end 5 to the paper output end 6 in one direction.

[0050] Wherein, the feeding main c...

Embodiment 2

[0059] A paper turning machine, see Figure 4 , including a frame 9, a drive unit 10, a paper turning mechanism 11, a transport mechanism 18, a paper transport mechanism 22, and a paper feeding mechanism as in Embodiment 1. The paper feeding mechanism is located on one side of the paper turning mechanism 11, and the paper feeding The feeding mechanism transmits the paper to be turned over to the paper turning mechanism 11, and the paper turning mechanism 11 turns over the paper to be turned over one side, the transport mechanism 18 is located under the paper turning mechanism 11, and the paper transport mechanism 22 is located at the position where the transport mechanism 18 is away from the paper turning mechanism. Below the mechanism 11, the feeding mechanism transfers the overturned paper to the paper turning mechanism 11, and the paper will be passed out from the paper turning mechanism 11, and the paper transmission mechanism 22 will place the paper on the transport mechan...

Embodiment 3

[0075] Embodiment three: the difference with embodiment two is:

[0076] see Figure 4 as well as Figure 10 , on the second conveying belt 183, be provided with the contact area 19 that is used to catch the paper that falls from the discharge end 17 at the first time, and the horizontal sliding table 26 is provided with the damping wheel 30, and the damping wheel 30 It is used to resist against the lower belt wall of the second transmission belt 183 opposite to the contact area 19 and close to the paper turning mechanism 11; during use, when the paper falls on the contact area 19 of the second transmission belt 183, the damping wheel 30 is also just in place. Against the lower belt surface of the second transmission belt 183 , sufficient supporting force of the second transmission belt 183 can be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com