One-time punching and forming equipment for automobile roof sunshade and production method thereof

A technology for sun visors and roofs, which is applied in the field of one-time punching and forming equipment for car roof sun visors, which can solve the problems of large investment in production equipment, high maintenance costs, and high manufacturing costs of roof sun visors, so as to reduce production costs , high production efficiency, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

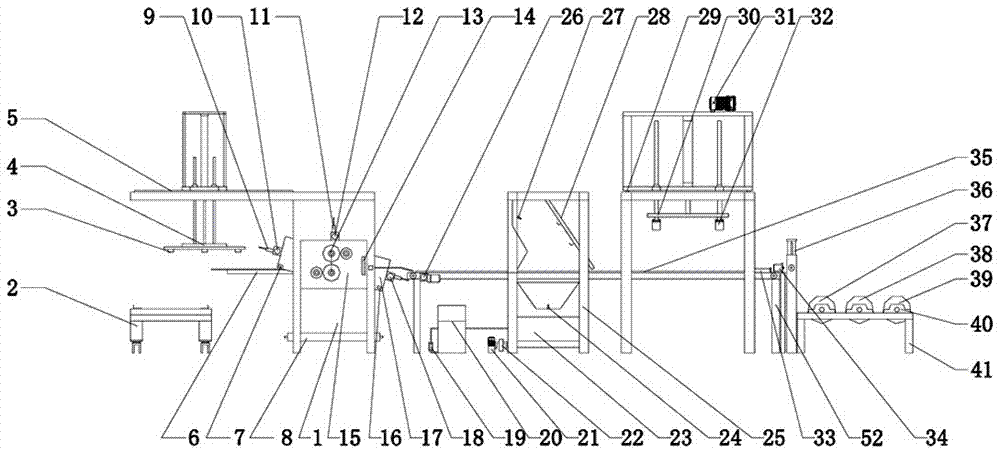

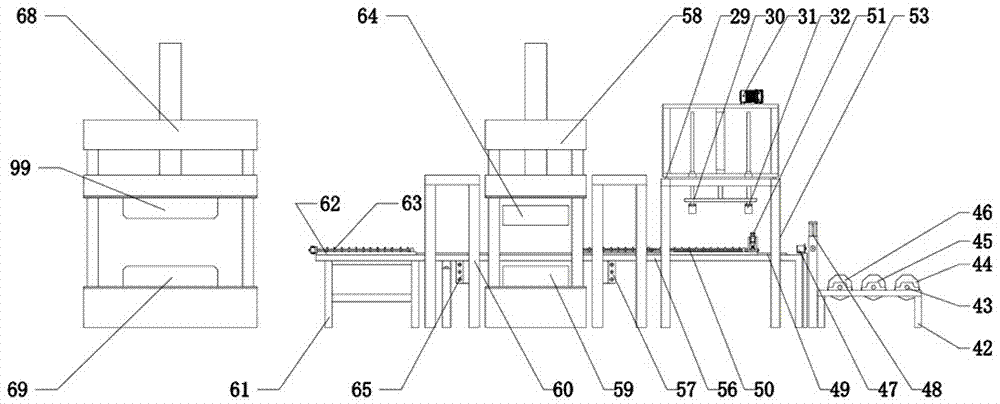

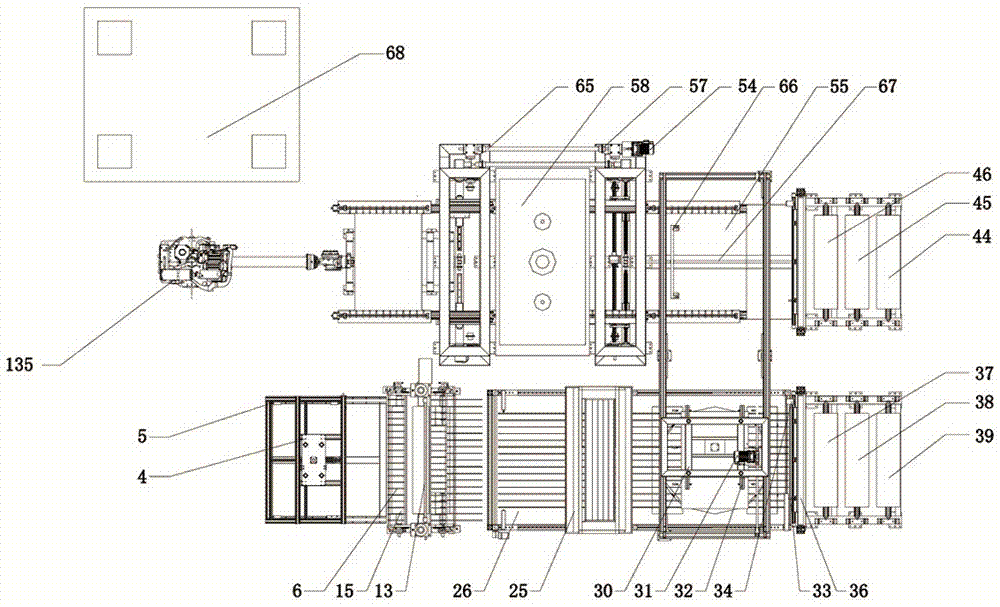

[0028] like Figure 1~13As shown, a car roof sun visor one-time punching and forming equipment includes two first production lines and a second production line arranged side by side. One end of the first production line is provided with a gluing device 1, and the other end is provided with a device for placing coiled materials. The loading frame A41 of A, the feeding side of the gluing device 1 is provided with a loading trolley 2 for placing PU foam and a grabbing device A3 for grabbing the PU foam on the loading trolley 2 to the gluing device, lifting Mechanism A4 is connected to grasping device A3 and can move vertically up and down, and slideway A5 carries lifting mechanism A4, which can move lifting mechanism A4 to a designated position laterally; the first production line is provided with a spray room 25 and coils A and The combined PU foam composed of PU foam is transferred to the grabbing device B32 of the second production line. The grabbing device B32 is used to grab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com