Nondestructive testing method for bubble mixed light soil embankment

A non-destructive testing, lightweight soil technology, applied to the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, instruments, and analysis materials, etc., it can solve problems such as attenuation, physical and mechanical performance degradation, and unfavorable embankment stability. Simple operation and remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

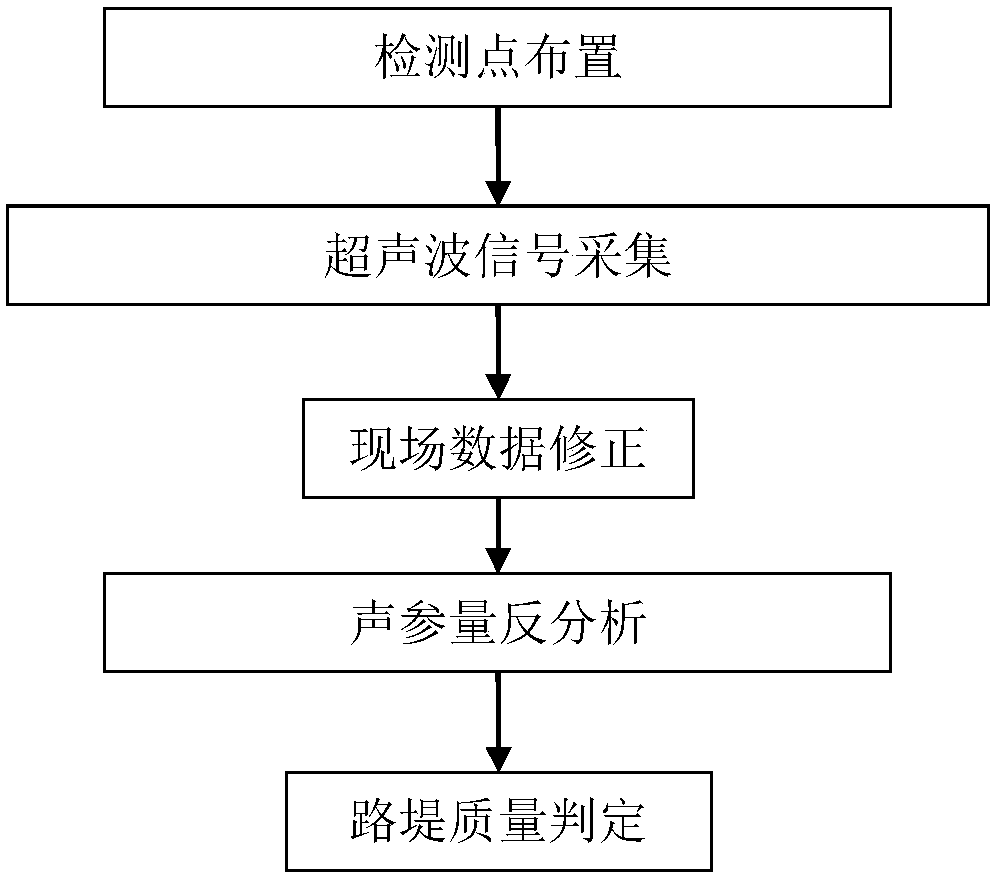

[0038] A kind of air bubble mixed light soil embankment field non-destructive testing method of the present invention, it comprises the following steps:

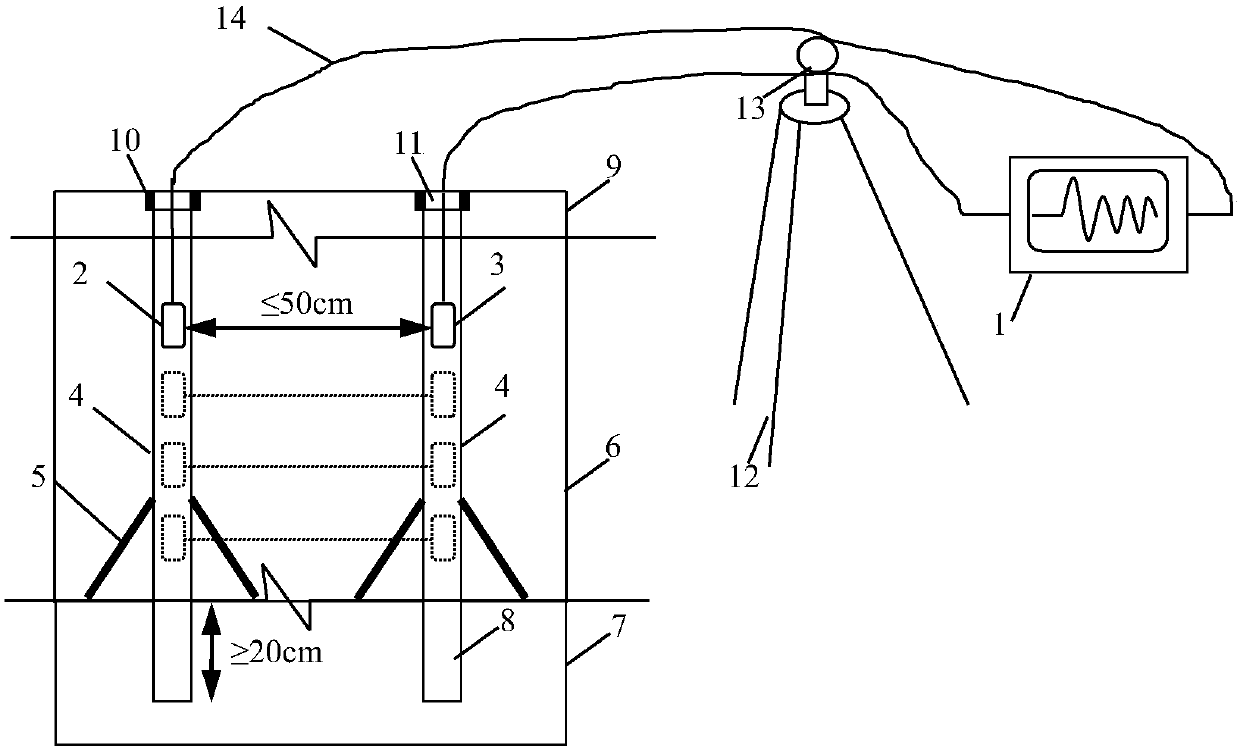

[0039] Check point layout. Such as figure 1 with figure 2 As shown, the air bubble mixed light soil embankment 6 is installed on the embankment before pouring. Acoustic tubes should be installed along the vertical section of the future operating road with the largest traffic flow, and a group should be installed every 50-100m. Each group of measuring points contains two acoustic tubes 4, and the maximum distance between the acoustic tubes shall not exceed 50cm. The acoustic tube should be inserted into the soil layer 7 at the bottom of the embankment for more than 20cm, and filled with cement mortar 8 to the bottom of the light soil embankment. When installing the acoustic tube 4 upwards, install three metal acoustic tube brackets 5 outside each acoustic tube 4 to maintain its verticality and stability, so as not to cau...

Embodiment 2

[0047] For a foam light soil road of an expressway, in order to sample the quality of its pouring, an inspection point was set at the exit of a ramp. The design thickness of the light soil embankment at the test point is 1.75m, and the temperature of the day is 35°, and the water content is 15%. The method of the present invention is used to carry out sampling inspection on the air bubble mixed light soil embankment. The construction mix ratio of air bubble mixed light soil embankment to be tested is: cement: water: air bubble group = 350(g): 215(g): 672.1(L). After the pavement is completed, the measuring point is drilled to bury the acoustic tube. The distance between the two acoustic tubes at the site is 50cm. The test is performed every 10cm within the range of 1.75m. A total of 17 test sections are obtained. Ultrasonic velocity of light soil embankment, see the table below.

[0048] The measured value of ultrasonic wave velocity of air bubble mixed light soil embankment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com