Material drying device

A drying device and material technology, applied in the direction of drying gas arrangement, wood drying, drying solid materials, etc., can solve the problems of uneven drying degree of finished products, inability to dry effectively, and different sizes, etc., to achieve fast drying speed and uniform drying The effect of thorough correction of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0014] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

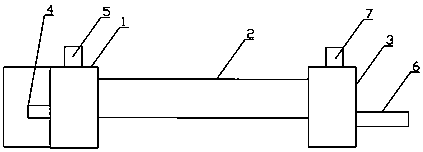

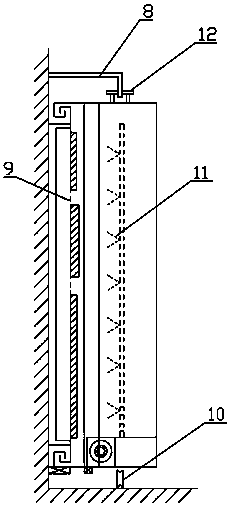

[0015] Such as figure 1 , 2 As shown, the material drying device includes a feed box 1, a drying box 2, and a discharge box 3. The top of the feed box 1 is provided with an air inlet, and the side of the feed box 1 is integrally provided with a feed port 4 , be provided with hot air blower 5 at air inlet; A slide rail 8 is provided between the feed box 1 and the drying box 2, between the drying box 2 and the discharge box 3, and a material placement platform 9 is provided on the slide rail 8 between the feed box 1 and the drying box 2 , the bottom of the material placement platform 9 is fixed with casters 10 and the casters 10 reciprocally slide o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com