Blast furnace slag liquid surface crust breaking device

A technology for crushing crusts and blast furnace slag, which is applied in the field of metallurgy and chemical industry, which can solve the problems of insufficient slag breaking force, inability to clean up heavy hammer residue, inaccurate slag breaking position, etc., to improve slag breaking force, facilitate maintenance and repair, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

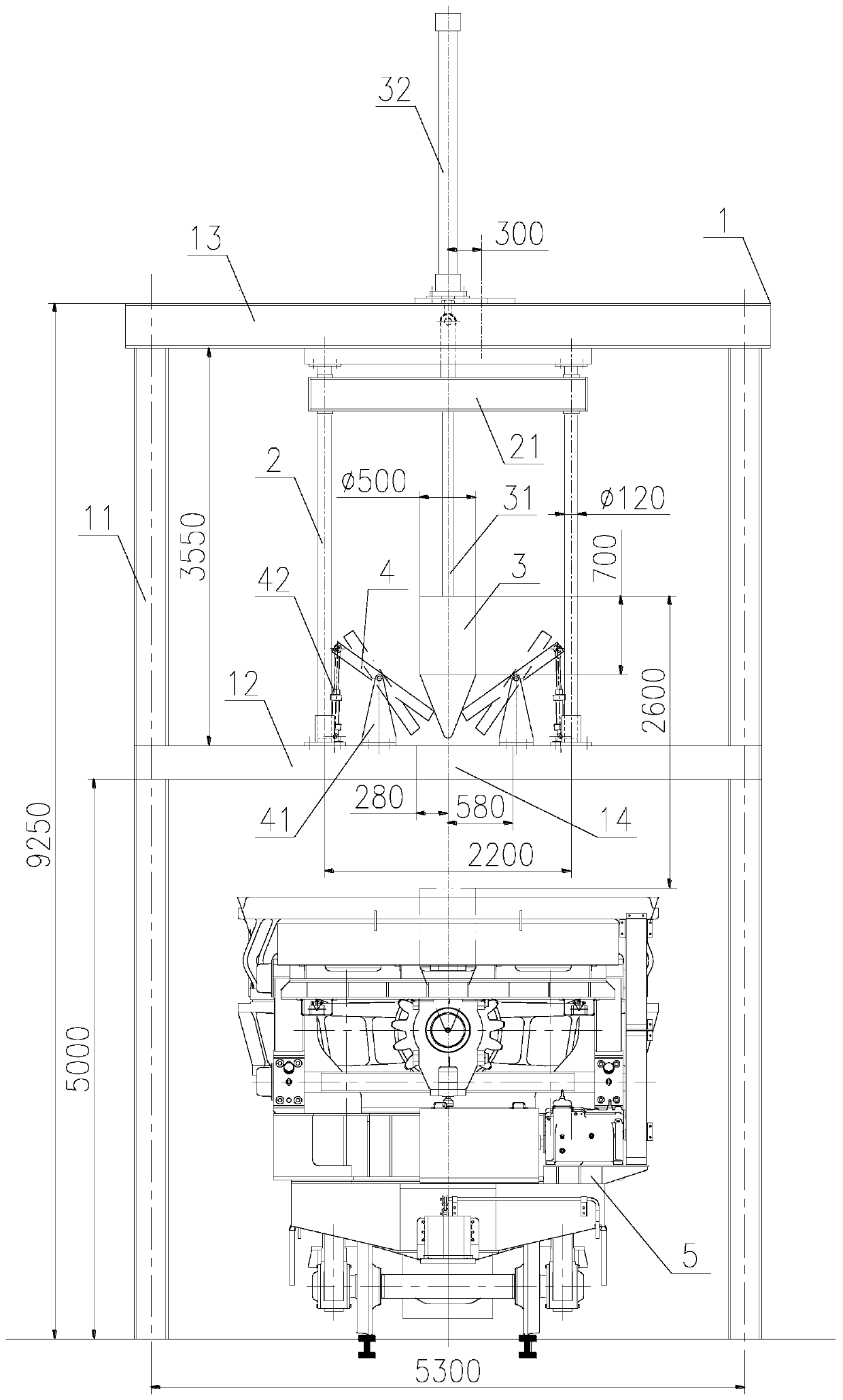

[0016] like figure 1 As shown, the blast furnace slag liquid surface crust breaking device of the present invention includes a support frame 1, a guide rod 2, a weight 3 and a slag cleaning plate 4, the support frame 1 includes a column 11 and a cross bar 13 connecting the top of the column 11, and the support frame A slag breaking platform 12 is set in the middle of the column 11 of 1. The slag-breaking platform 12 is used for installing the slag-breaking devices such as the guide bar 2 and the slag-cleaning plate 4 and as a platform for manual operation. Two guide rods 2 are vertically arranged between the cross bar 13 and the slag-breaking platform 12. In addition, more than two guide rods 2 can also be provided. A horizontal connecting rod 21 is set between the two guiding rods 2, and the horizontal connecting rod 21 Can slide up and down along the guide rod 2.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com